Technology for efficiently purifying glycol obtained through oxalate hydrogenation

A technology for purifying oxalate and ethylene glycol, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of destroying the marine ecological environment, unscientific utilization, and consumption of natural gas resources, so as to reduce energy consumption, Reduce negative impact and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

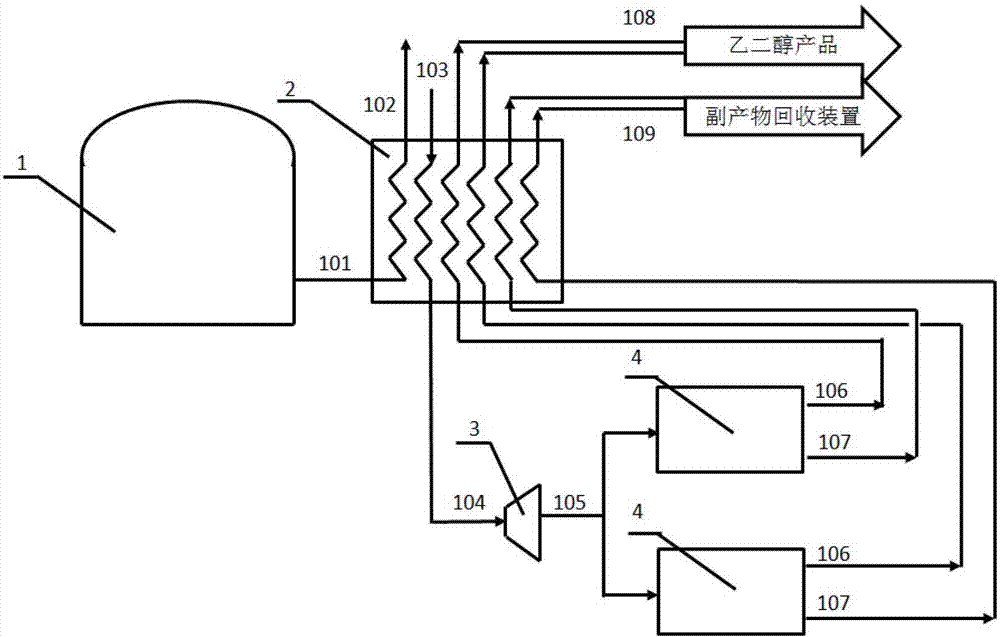

[0021] figure 1 It is a process flow diagram of the present invention, with reference to figure 1 As shown, the apparatus used includes a heat exchange unit 2, a supplemental refrigeration unit 3, and a separation unit 4 for ethylene glycol, 1,2-propanediol and 1,2-butanediol. The heat exchange unit 2 is connected to the LNG storage tank 1 through a pipeline 101, and the LNG cryogenic liquid at -162°C is heated up to room temperature and vaporized through the heat exchange unit 2. The gasified natural gas is transported by the natural gas pipeline 102 to the natural gas usage place outside the boundary area. The temperature is 180°C, the pressure is 30bar, and the crude product of ethylene glycol is produced by hydrogenation of oxalate (the mass fraction of ethylene glycol is 70%, the mass fraction of 1,2-propanediol is 15%, and the mass fraction of 1,2-butanediol is The mass fraction is 15%) enters the heat exchange unit 2 through the crude product delivery pipeline 103 at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com