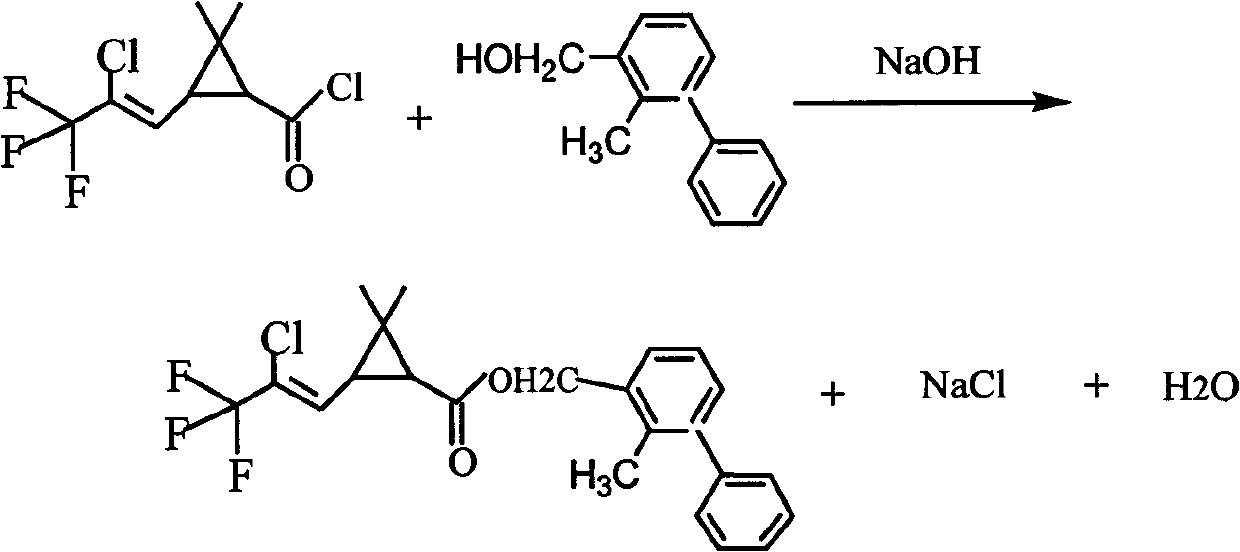

Method for preparing bifenthrin

A technology of bifenthrin and bifenthrin, which is applied in the field of preparing bifenthrin, can solve the problems of increasing the difficulty and workload of wastewater treatment, failing to meet discharge standards, and high ammonia nitrogen content, so as to reduce raw material consumption and lighten the The effect of labor intensity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In a 250ml four-necked flask equipped with stirring, thermometer, condenser, and dropping device, first add 100.0 grams of toluene and 30.0 grams (0.1498 mol) of biphenyl alcohol, and start stirring. Raise the temperature to 50°C, stir and dissolve for 0.5 hours, cool down to 10°C, and then add 6.3 grams of sodium hydroxide (96.0% content, 40 grams of water, and 0.1 grams of catalyst tetrabutylammonium chloride.

[0032] Raise the temperature to 18°C, start to slowly add 40.0 grams (0.1514mol) of trifluorochrysanthemum acid chloride dropwise, the dropwise addition time is 4 hours, measure the pH of the reaction solution after the dropwise addition is 8.5, keep the reaction at 18°C for 0.5-1.0 hours, Sampling was carried out for central control (gas chromatography area normalization method), the content of biphenyl alcohol was detected to be 0.8%, and the stirring was stopped.

[0033] Let the reaction materials stand for 0.5-1.0 hours, separate layers, wash the upper ...

Embodiment 2

[0035] In a 250ml four-necked flask equipped with stirring, thermometer, condenser, and dropping device, first add 100.0 grams of toluene and 30.0 grams (0.1498 mol) of biphenyl alcohol, and start stirring. Raise the temperature to 53°C, stir and dissolve for 0.8 hours, then cool down to 13°C, then add 8.82 grams of potassium hydroxide, 40 grams of water, and 0.1 grams of catalyst tetrabutylammonium chloride.

[0036] Raise the temperature to 19°C, start to slowly add 40.0 grams (0.1514mol) of trifluorochrysanthemum acid chloride dropwise, the dropwise addition time is 4.5 hours, measure the pH of the reaction solution after the dropwise addition is 10.6, keep the reaction at 19°C for 0.5-1.0 hours, Sampling was carried out for central control (gas chromatography area normalization method), the content of biphenyl alcohol was detected to be 1.5%, the temperature was raised to 45-50° C., stirred for another 1.0 hour, and the stirring was stopped.

[0037] Let the reaction mater...

Embodiment 3

[0039] In a 250ml four-necked flask equipped with stirring, thermometer, condenser, and dropping device, first add 100.0 grams of toluene and 30.0 grams (0.1498 mol) of biphenyl alcohol, and start stirring. Raise the temperature to 55°C, stir and dissolve for 1.0 hour, then cool down to 15°C, then add 8.0 g of sodium carbonate, 40 g of water, and 0.1 g of catalyst tetrabutylammonium chloride.

[0040] Raise the temperature to 20°C, start to slowly add 40.0 grams (0.1514mol) of trifluorochrysanthemum acid chloride dropwise, the dropwise addition time is 5 hours, measure the pH of the reaction solution after the dropwise addition is 7.6, keep the reaction at 20°C for 0.5-1.0 hours, Sampling was carried out for central control (gas chromatography area normalization method), the content of biphenyl alcohol was detected to be 1.35%, the temperature was raised to 45-50° C., stirred for another 1.0 hour, and the stirring was stopped.

[0041] Subsequent steps are the same as in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com