Novel process for synthesizing N-vinyl pyrrolidone (NVP)

A technology of vinylpyrrolidone and pyrrolidone, which is applied in the new process field of NVP synthesis of N-vinylpyrrolidone, can solve the problems of flammability and explosion of acetylene, and achieve the effects of low reaction temperature, increased heat transfer area and stable solution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

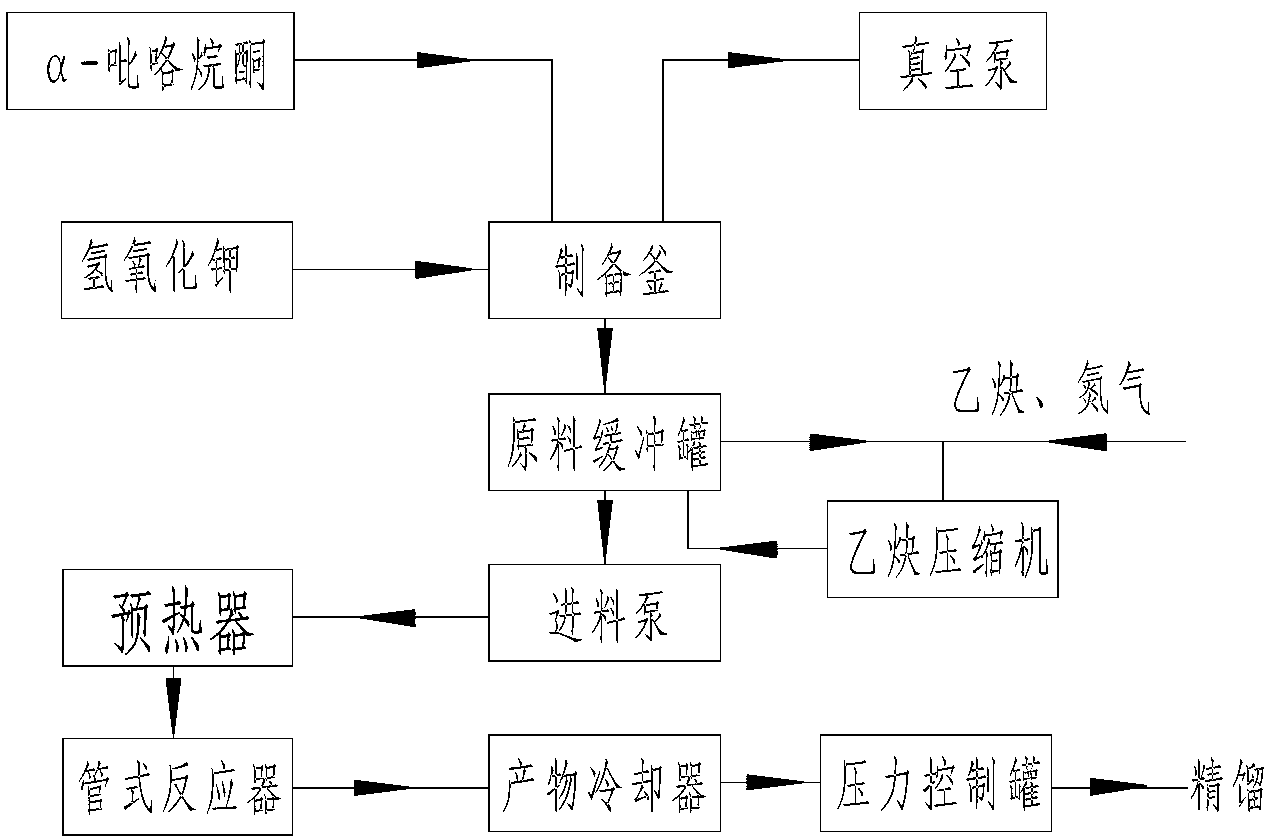

[0042] Add 1000 kg of α--pyrrolidone and 15 kg of potassium hydroxide to the preparation kettle, keep the pressure at -0.095 Mpa, raise the temperature to 110°C to make potassium pyrrolidone, and mix acetylene and nitrogen at a flow rate of 120 L / h at a pressure of 1.5 Mpa and 30°C, dissolve potassium pyrrolidone and put it into the raw material buffer tank. The material passes through the bottom of the raw material buffer tank to the feeding pump to pressurize to 1.5Mpa, and is sent to the preheater at a flow rate of 200L / h to raise the temperature to the reaction temperature of 130°C. After the heater, it is sent into the casing reactor formed by connecting 3-stage reactors with an inner diameter of ¢50 mm and a length of 60 meters in series. The reaction temperature is maintained at 180° C., and the reaction residence time is 1.5 hours. After the reaction is completed, the cooler is cooled to normal temperature, the cooled crude product enters the pressure control tank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com