Grafting treatment apparatus and grafting treatment method for battery diaphragm material

A technology for battery separators and processing equipment, which is applied to fiber processing, battery components, circuits, etc., and can solve problems such as high production cost, expensive equipment, waste of grafted monomer solution, etc., to reduce equipment investment and reduce Comprehensive cost and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

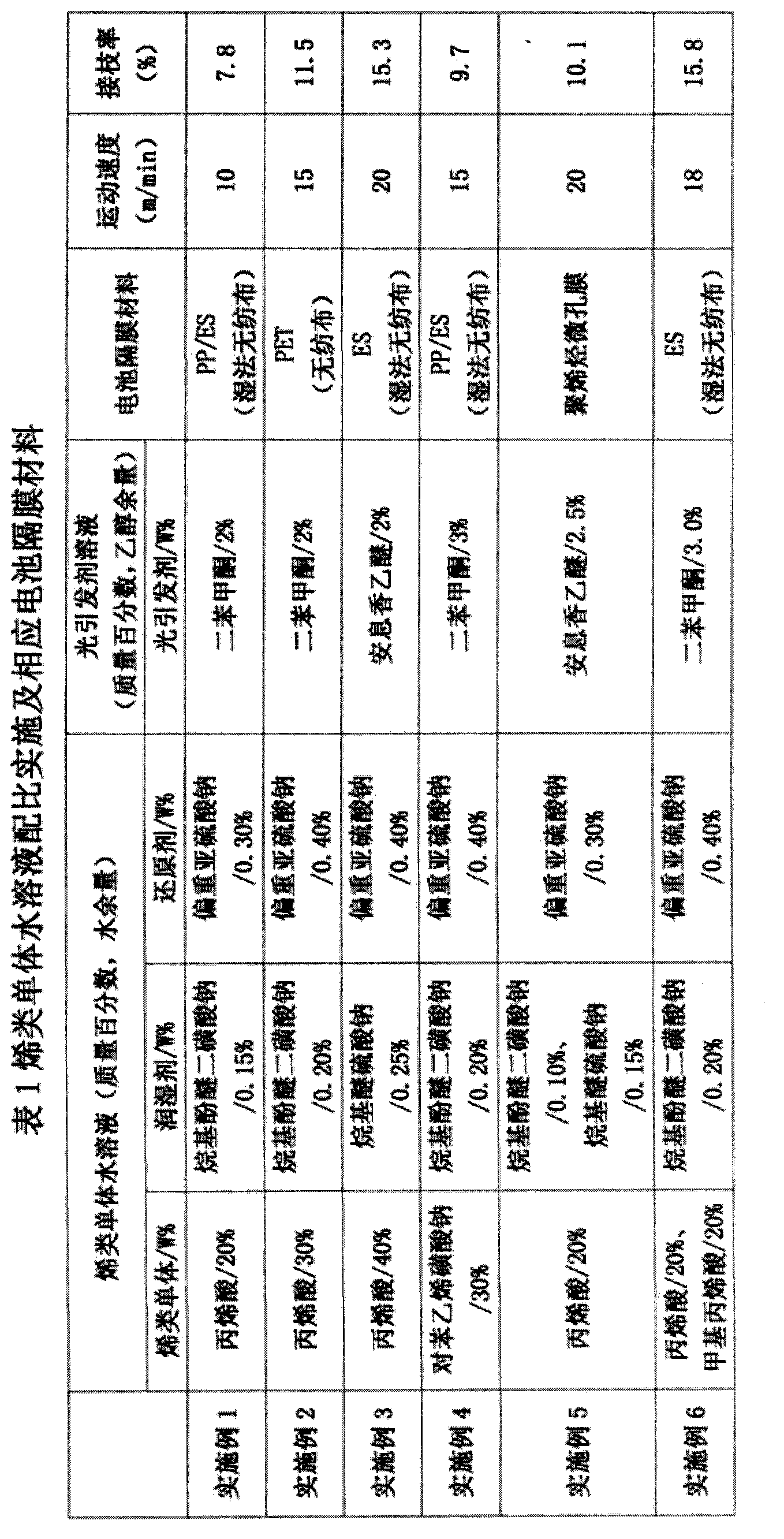

[0029]The specific operations used in the examples are selected by those skilled in the art within a certain range of conventional techniques, and can be adjusted for different products. For details, please refer to the cited documents, which are common technical means in the field.

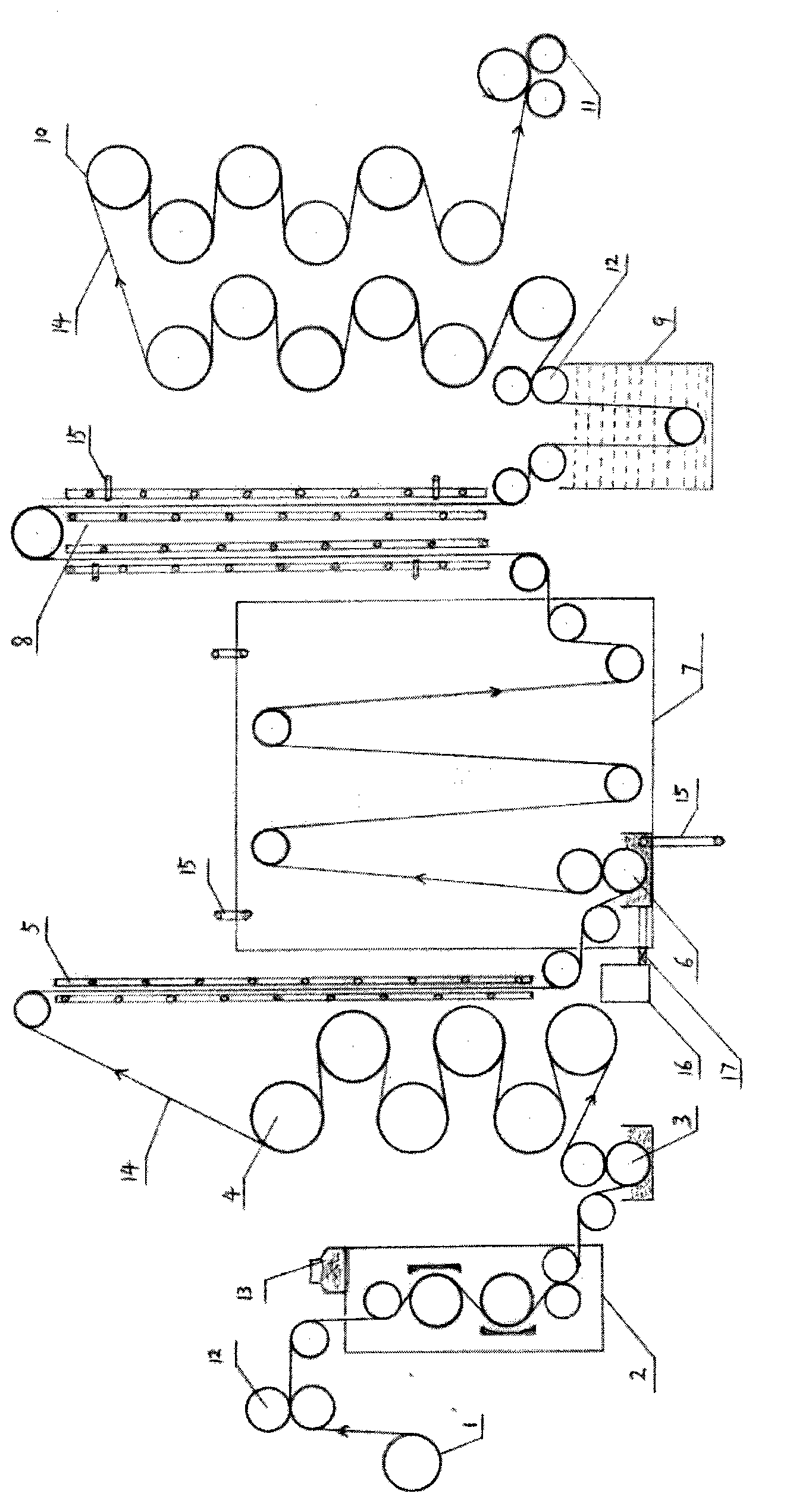

[0030] like figure 1 As shown, a battery separator material graft treatment equipment mainly includes a battery separator material 14 unwinding device 1, a corona treatment machine or a normal temperature plasma treatment machine 2, a photoinitiator impregnating device 3, a photoinitiator drying device 4, an ultraviolet Light irradiation device 5, grafting reaction device 7 containing ethylenic monomer solution dip coating device 6, ultraviolet irradiation grafting device 8, water washing device 9, drying device 10, winding device 11, and each part is sequentially penetrated The guide device 12 and the guide roller that got up. The corona treatment machine or the normal temperature plasma treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com