Preparation method for PET-substrate rubber pressure-sensitive adhesive tape and adhesive tape

A pressure-sensitive tape, rubber-type technology, applied in adhesives, film/sheet adhesives, coatings, etc., to achieve the effects of avoiding pollution, improving adhesion, long-term fixing or protecting objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

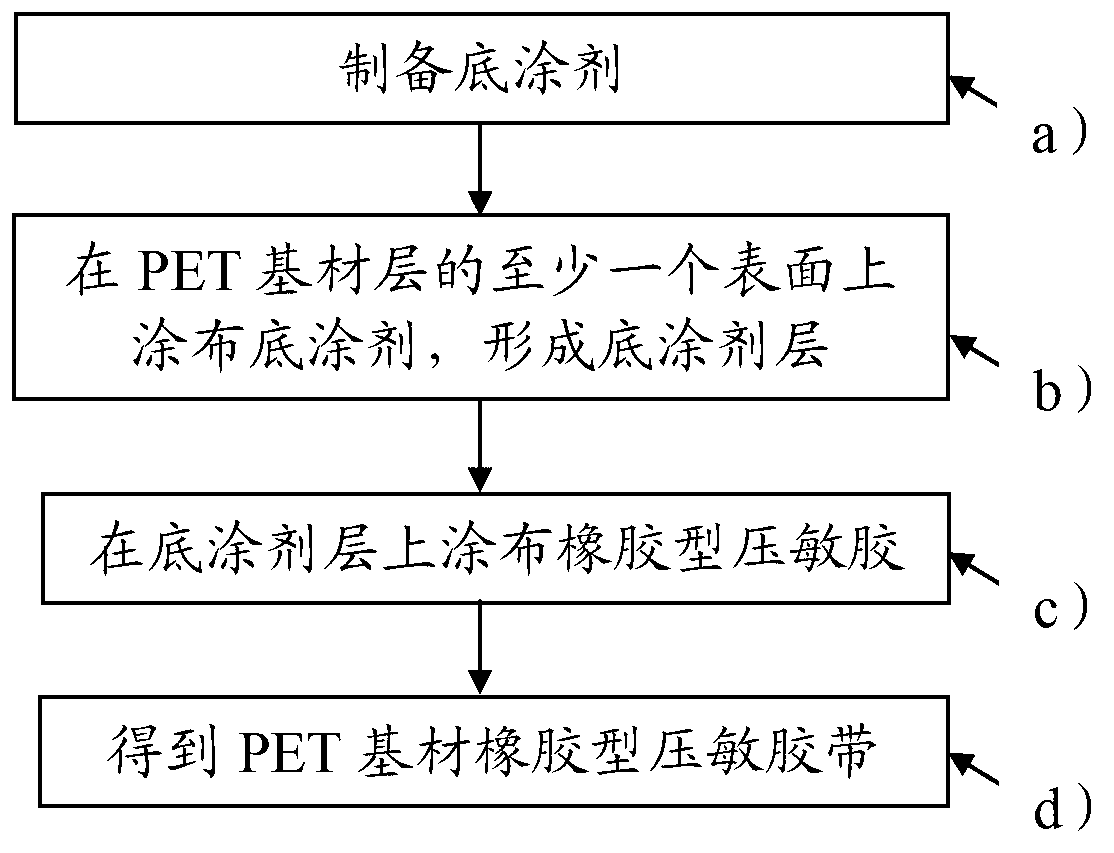

[0042] The embodiment of the present invention discloses a method for preparing a PET-based rubber-type pressure-sensitive adhesive tape, the operation steps of which include:

[0043] a), prepare primer;

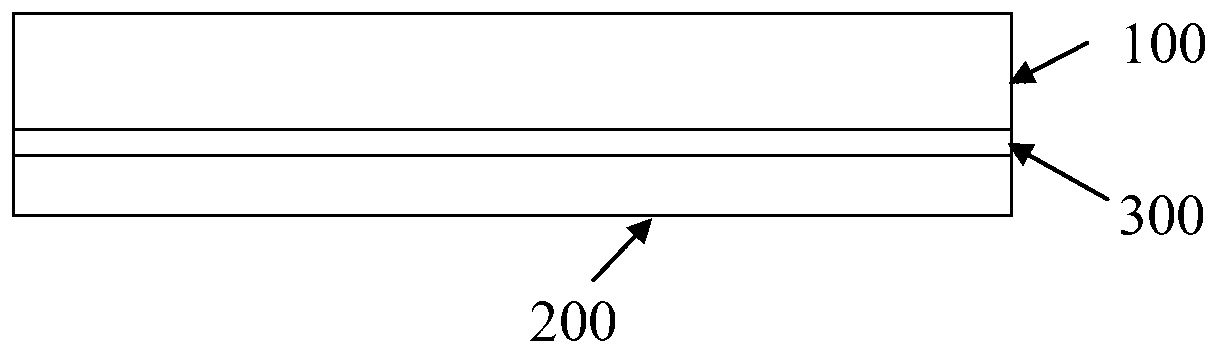

[0044] b), coating a primer on at least one surface of the PET substrate layer to form a primer layer;

[0045] c) Coating rubber-type pressure-sensitive adhesive on the primer layer;

[0046] d) Obtain a PET-based rubber-type pressure-sensitive adhesive tape;

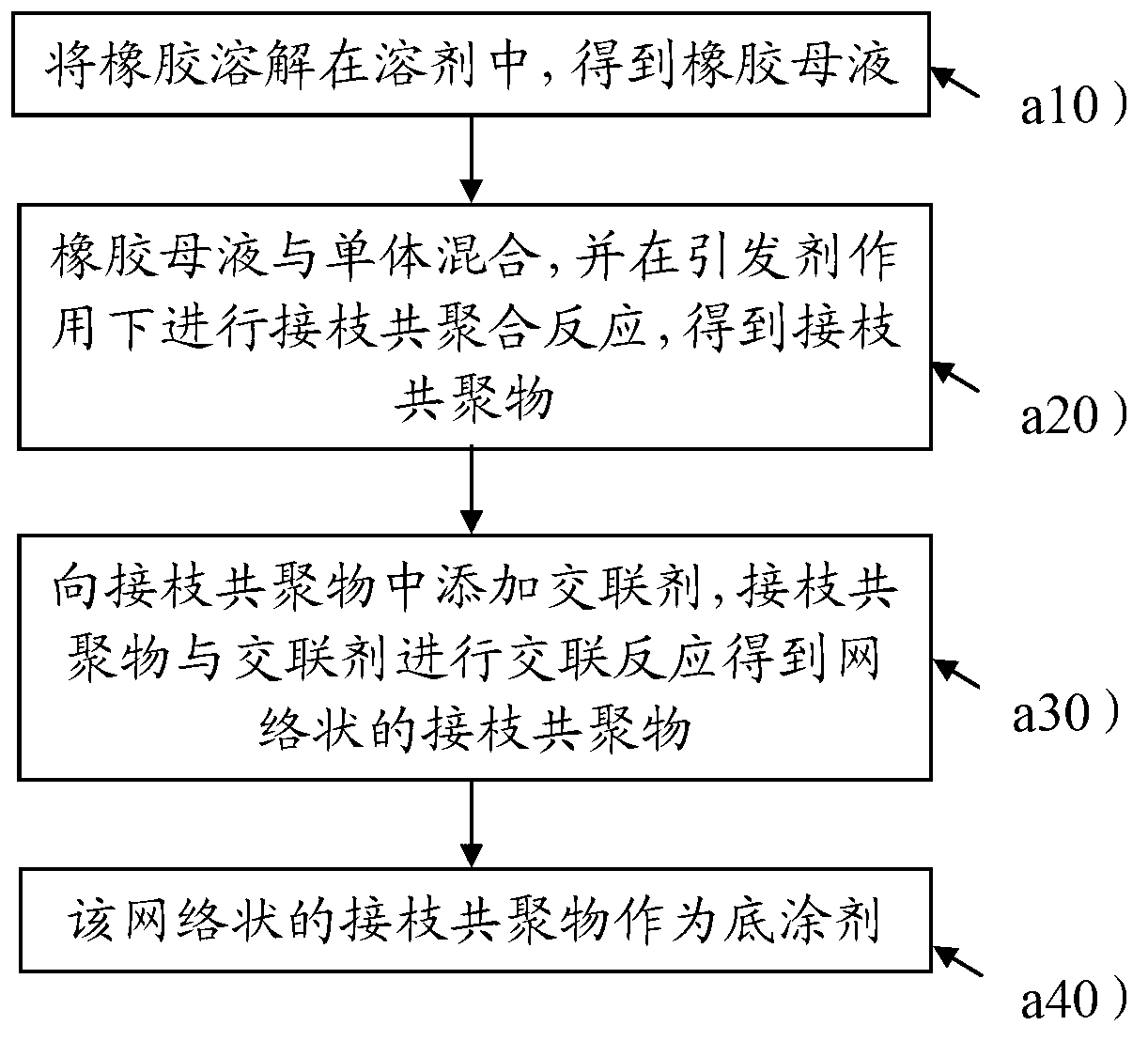

[0047] Wherein, the primer is a graft copolymer, and the graft copolymer includes a rubber main chain and a polar graft polymerized side chain.

[0048] Preferably, step a) includes:

[0049] a10), dissolving the rubber in a solvent to obtain a rubber mother liquor;

[0050] a20), in the reaction device, mix the rubber mother liquor obtained in the above step a10) with the monomer, and carry out the graft copolymerization reaction under the action of the initiator;

[0051] a30), after the graft copolymerizatio...

Embodiment 1

[0069] See figure 1 , figure 2 and image 3 Shown, a kind of preparation method of PET substrate rubber type pressure-sensitive adhesive tape, its operation step comprises:

[0070] a), prepare primer, specifically include:

[0071] a10) Add 400g of toluene and 100g of natural rubber into a 1L four-necked reaction flask equipped with a stirring device, a condenser, a thermometer, a dropping funnel, and nitrogen gas, and stir evenly. After the rubber is completely dissolved, the rubber mother liquor is obtained;

[0072]a20), in the reaction bottle, add 0.057g of acrylic acid, 2.4g of butyl acrylate, 5.74g of methyl methacrylate (three mixed monomers) and 0.03g of benzoyl peroxide to the rubber mother liquor in the above step a10). (initiator), stirred and heated to 78°C for 2 hours, then added dropwise 0.14g of acrylic acid, 5.86g of butyl acrylate, 14g of methyl methacrylate (three kinds of mixed monomers) and 0.07g of benzoyl peroxide (initiator Add the mixture of agent...

Embodiment 2

[0082] See also figure 1 , figure 2 and image 3 Shown, a kind of preparation method of PET substrate rubber type pressure-sensitive adhesive tape, its operation step comprises:

[0083] a), prepare primer, specifically include:

[0084] a10) Add 400g of toluene and 100g of natural rubber into a 1L four-necked reaction flask equipped with a stirring device, a condenser, a thermometer, a dropping funnel, and nitrogen gas, and stir evenly. After the rubber is completely dissolved, the rubber mother liquor is obtained;

[0085] a20), in the reaction bottle, add 0.11g of acrylic acid, 7.9g of methyl methacrylate (two mixed monomers) and 0.03g of benzoyl peroxide (initiator) to the rubber mother liquor in the above step a10), and stir Raise the temperature to 80°C for 2 hours, then add dropwise a mixture of 0.2g of acrylic acid, 19.7g of methyl methacrylate (two mixed monomers) and 0.07g of benzoyl peroxide (initiator), and complete the dropwise addition within 2 hours , under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com