Method for producing cationic type composite cotton yarn imitation threads

A cationic and production method technology, applied in the field of textile fibers, can solve the problems of poor anti-pilling performance, insufficient compactness, high production cost, etc., and achieve the effects of reducing production cost, improving production efficiency and shortening the processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

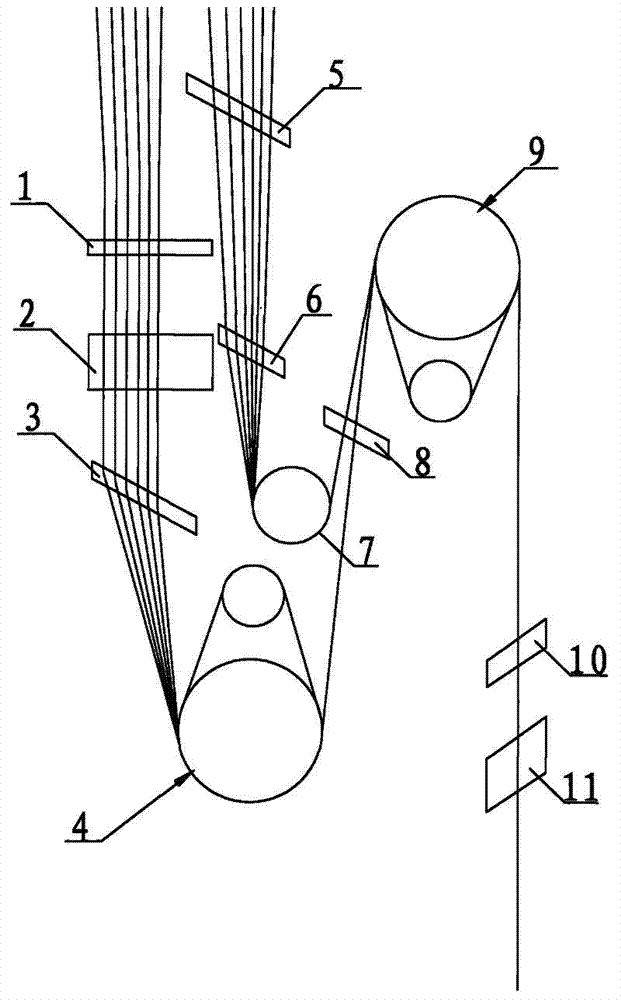

Image

Examples

Embodiment 1

[0025] Cationic polyester (CDP) with an intrinsic viscosity of 0.64dl / g is used as the raw material, and the molar content of the modified unit bishydroxyethyl isophthalate-5-sulfonate (SIPE) relative to terephthalic acid is 5%. TiO 2 The content is 0.3%. Through the POY\FDY composite fiber one-step spinning equipment, 147dtex / 108f POY\FDY composite fiber (ITY) is spun, and the elongation at break is 28%. Among the composite fibers, POY is 83dtex / 72f, the single filament fineness is 1.2dtex, and the cross section is circular; FDY is 64dtex / 36f, the single filament fineness is 1.8dtex, and the cross section is circular; the mass ratio of POY component to FDY component is 1:0.77 .

[0026] False twist the above ITY on a 33H texturing machine, control the draft ratio to 1.05, the temperature of the first hot box is 140°C, the temperature of the second hot box is 130°C, the processing speed is 400m / min, and the pre-screen pressure is 1.8MPa.

[0027] The cationic composite cotto...

Embodiment 2

[0029] The normal pressure dyeable cationic polyester (ECDP) with an intrinsic viscosity of 0.66dl / g and modified units of SIPE and polyether (PEG2000) is used as the raw material, wherein the molar content of SIPE relative to terephthalic acid is 3%, and PEG2000 4% relative to the weight of terephthalic acid, TiO 2The content is 2.5%. Through the POY\FDY composite fiber one-step spinning equipment, 300dtex / 144f POY\FDY composite fiber (ITY) is spun, and the elongation at break is 36.5%. Among the composite fibers, POY is 150dtex / 72f, single filament fineness is 2.1dtex, and cross-section is quatrefoil; FDY is 150dtex / 72f, single filament fineness is 2.1dtex, and cross-section is pentagonal; the mass ratio of POY component to FDY component is 1 :1.

[0030] False twist the above ITY on a 33H texturing machine, control the draft ratio to 1.1, the temperature of the first hot box is 160°C, the temperature of the second hot box is 140°C, the processing speed is 350m / min, and the...

Embodiment 3

[0033] Cationic polyester (CDP) with an intrinsic viscosity of 0.69dl / g is used as the raw material, and the molar content of the modified unit bishydroxyethyl isophthalate-5-sulfonate (SIPE) relative to terephthalic acid is 1.5%. TiO 2 The content is 1.8%. Through the POY\FDY composite fiber one-step spinning equipment, 100dtex / 72f POY\FDY composite fiber (ITY) is spun, and the elongation at break is 40%. Among the composite fibers, POY is 45dtex / 48f, single filament fineness is 0.93dtex, and the cross-section is pentalobal; FDY is 55dtex / 24f, single filament fineness is 2.3dtex, and the cross-section is circular; the mass ratio of POY component to FDY component is 1: 1.2.

[0034] False twist the above ITY on a 33H texturing machine, control the draft ratio to 1.2, the temperature of the first hot box is 150°C, the temperature of the second hot box is 100°C, the processing speed is 480m / min, and the pre-wire pressure is 1.4MPa.

[0035] The cationic composite cotton-like y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com