Grain depot intellectualization integrated control system and application method thereof

A technology of comprehensive control and grain depot, applied in the direction of control/regulation system, comprehensive factory control, comprehensive factory control, etc., can solve the problems of easily corroded electronic components, high maintenance cost, moisture, etc., to avoid corrosion of temperature sensors, improve Effect of monitoring, effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

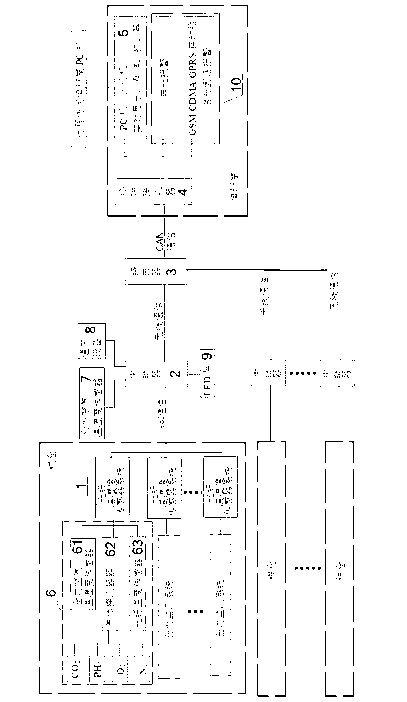

[0069] see figure 1 – Figure 5 , an intelligent integrated control system for grain depots, the system monitors multiple grain bins at the same time, and each grain bin is provided with a repeater 2. Taking a grain bin as an example, its structure is as follows:

[0070] Warehouse air temperature and humidity sensor 61, gas detector 62 (including carbon dioxide detector, phosphine detector, oxygen detector and nitrogen detector), optical fiber temperature sensor 63 (the number included in each optical fiber temperature and humidity sensor system 1 The output end of the fiber optic temperature and humidity sensor system 1 (1-20 pieces) is connected to the input end of the fiber optic temperature and humidity sensor system 1, and the output end of the fiber optic temperature and humidity sensor system 1 and the outside air temperature and humidity sensor 7 are connected to the relay. The input end of the router 2 is connected, the output end of the repeater 2 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com