Forming method of metallic oxide layer in resistive random access memory

A technology of resistive memory and oxide layer, which is applied in the direction of electrical components, etc., can solve the problems that the oxide layer cannot provide a high-quality oxide layer that meets the requirements, and the resistance change performance of the metal oxide layer is greatly affected, so as to improve the quality of the oxide layer, Good uniformity and high oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

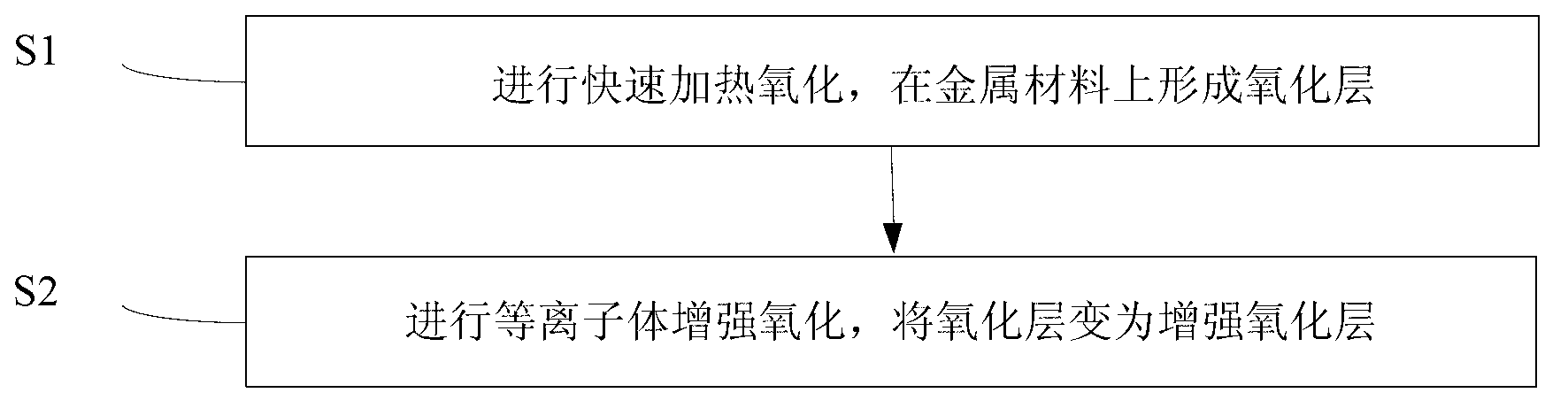

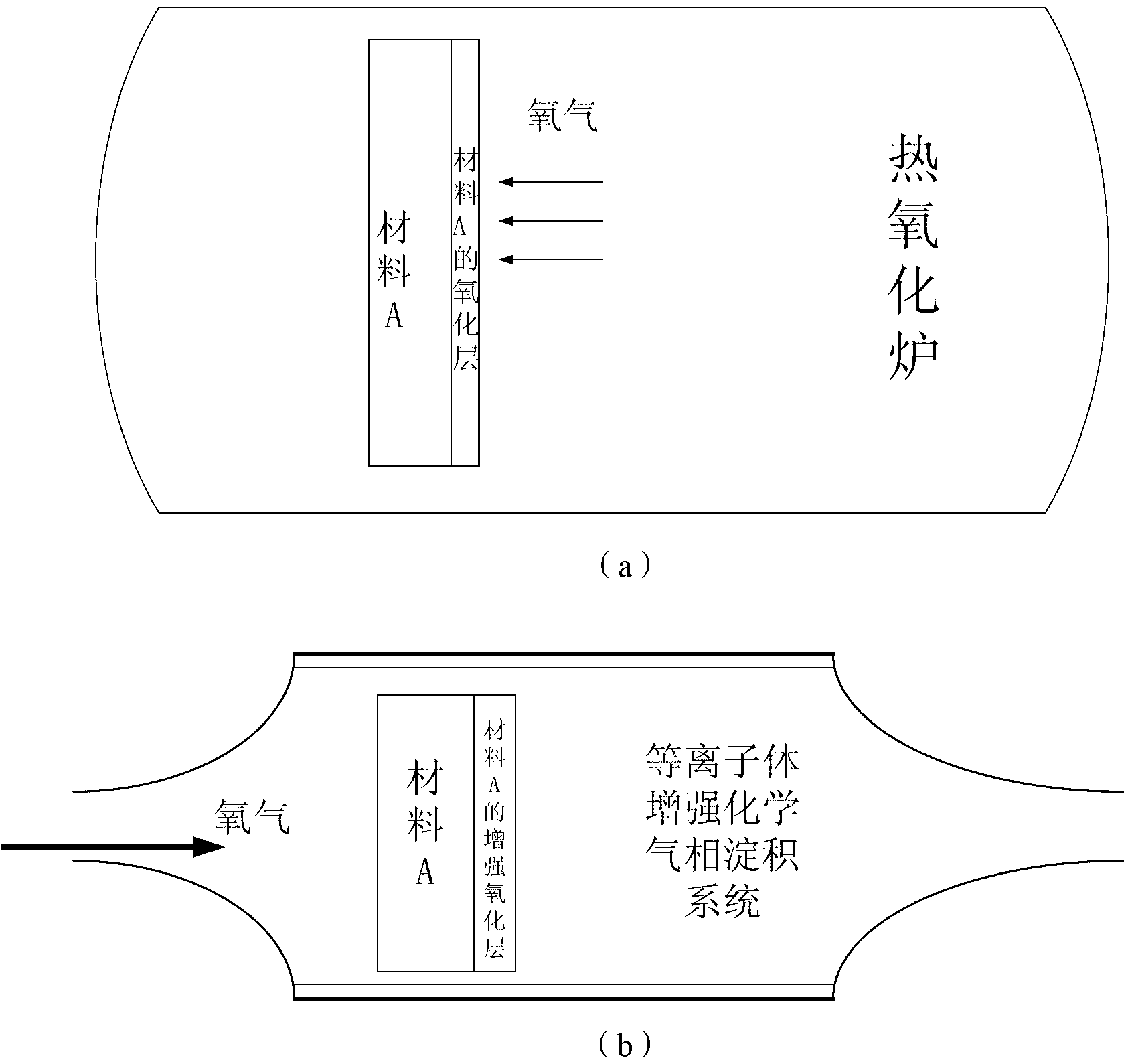

[0026] To enable those skilled in the art to better understand the present invention, the following is combined figure 2 Describe a specific example as follows:

[0027] Such as figure 2 Shown is a schematic diagram of the step-by-step process of the present invention. The first step is the traditional thermal oxidation process. Dry oxygen oxidation of material A is carried out in a thermal oxidation furnace (horizontal / vertical oxidation system). The temperature for rapid heating and oxidation is 400-500℃, 50-200s, according to The oxide layer thickness required by the device design adjusts the process parameters to a certain extent. The common oxide layer thickness is 30-100nm. In the second step, the material is put into the plasma enhanced chemical vapor deposition system (including cold wall parallel plate / hot wall parallel plate / electron cyclotron resonance, etc.), oxygen is introduced to create an oxygen atmosphere, and plasma enhanced chemical vapor deposition is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com