Negative pole of enzymatic biofuel cell as well as preparation method and application of negative pole

A biofuel cell and cathode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of few carbon nanotube chemical binding sites, affecting the application of carbon nanotubes, prone to agglomeration, etc., and achieving a simple and effective preparation method. , good electrical conductivity, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

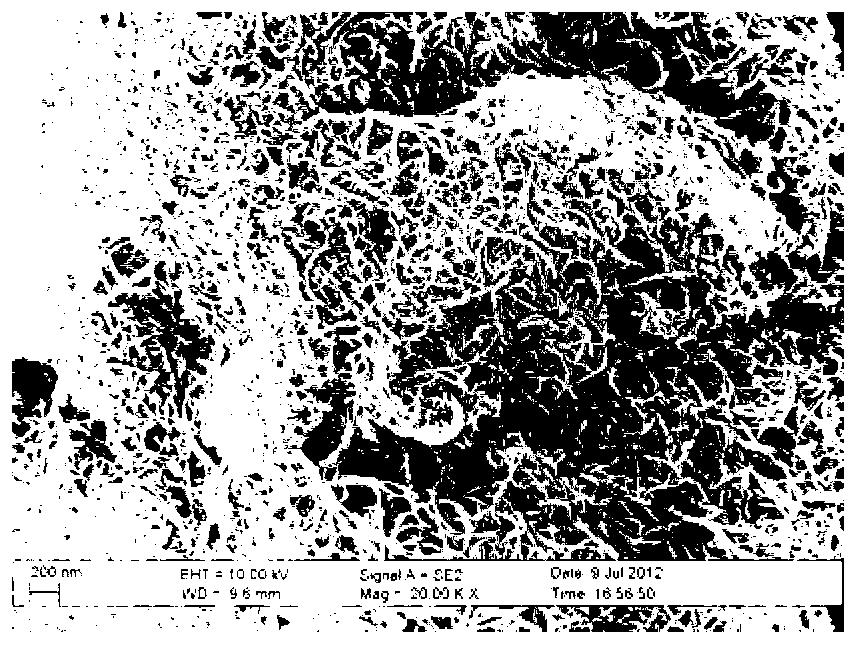

[0057] I. Preparation of bioanode CNT / CB / HRP for enzyme biofuel cell:

[0058] (1) Take 10 mg of carbon nanotubes, soak them in acetone for 30 minutes, then filter, wash with distilled water, and dry; then add the cleaned carbon nanotubes into concentrated H 2 SO 4 / concentrated HNO 3 (The volume ratio is 3:1) Ultrasound at 30°C and 100Hz for 6h in the mixed acid solution, filter, clean with distilled water, and dry in a vacuum oven at 100°C for 4h to obtain treated carbon nanotubes;

[0059] (2) Take 4 mg of the carbon nanotubes treated in step (1) and add them to an aqueous solution containing 1 mmol / L Cymbal blue. After ultrasonication at 40 °C and 100 Hz for 6 h, stir the solution continuously, add 1 g of NaCl, react at 60 °C for 1 h, and then Add 0.1g Na 2 CO 3 , reacted at 80°C for 8h to obtain the mixture; the mixture was centrifuged and dialyzed to remove unfixed Cymbal blue, then dried in a vacuum oven at 80°C, and ground to obtain a multi-walled carbon nanotube / ...

Embodiment 2

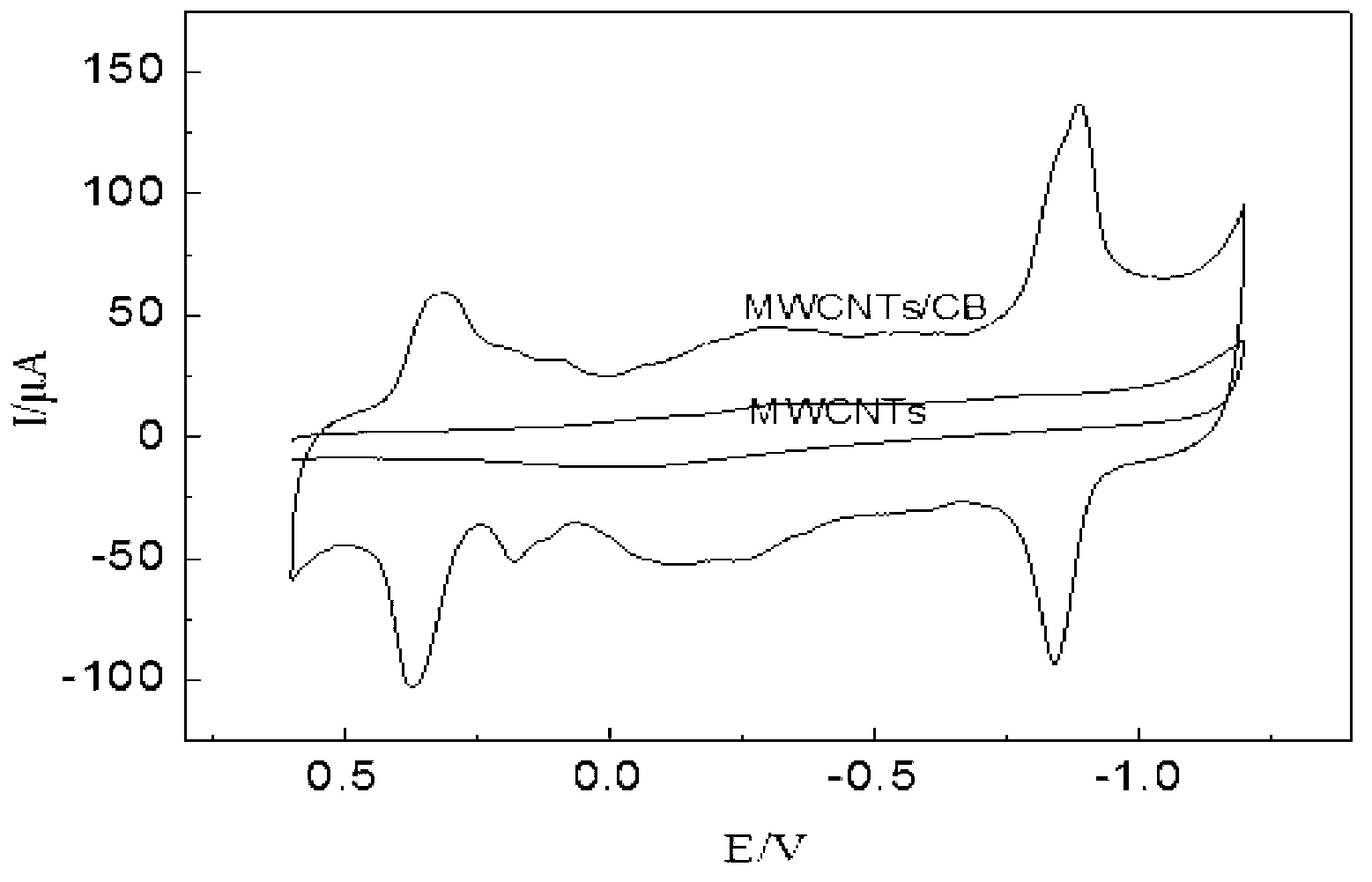

[0072] I. Preparation of biocathode CNT / CB / HRP for enzyme biofuel cell:

[0073] The preparation method of the biocathode CNT / CB / HRP of the enzyme biofuel cell is the same as that in Example 1.

[0074] II. Anode manufacturing method and battery assembly test:

[0075] Anode and anode chamber solution are with embodiment 1;

[0076] The cathode chamber solution is 0.2mol / L, PBS phosphate buffer solution with pH=7.0, which contains 0.2mol / L tert-butanol peroxide;

[0077] The battery assembly method is the same as in Example 1.

[0078] It is detected that the maximum power density of the enzyme biofuel cell obtained in this embodiment is 58 μW / cm 2 .

Embodiment 3

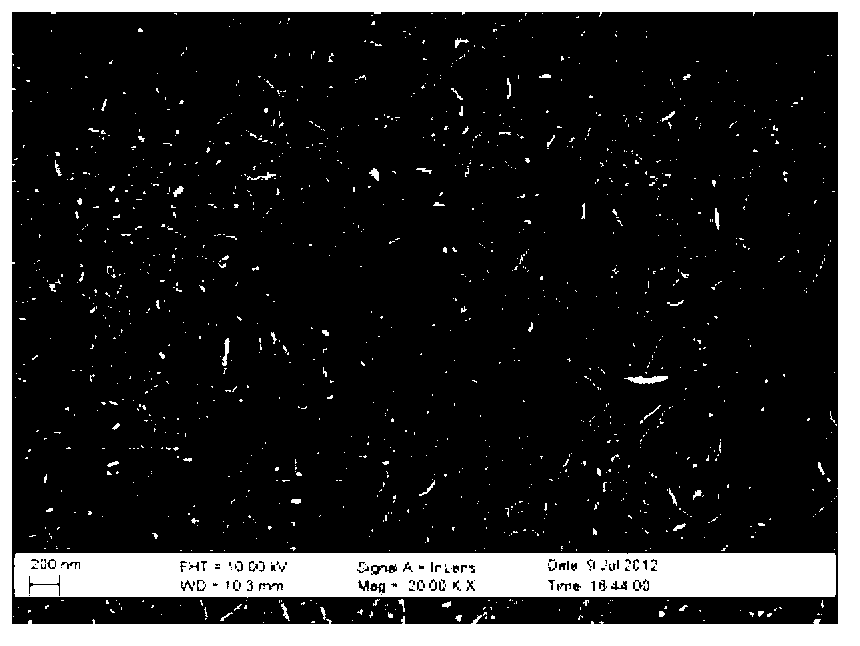

[0080] I. Preparation of raw cathode CNT / HRP for enzyme biofuel cell:

[0081](1) Take 10 mg of carbon nanotubes, soak them in acetone for 30 minutes, then filter, wash with distilled water, and dry; then add the cleaned carbon nanotubes into concentrated H 2 SO 4 / concentrated HNO 3 (The volume ratio is 3:1) Ultrasound at 30°C and 100Hz for 6h in the mixed acid solution, filter, clean with distilled water, and dry in a vacuum oven at 100°C for 4h to obtain treated carbon nanotubes;

[0082] (2) Take 4 mg of carbon nanotubes treated in step (1) and add them to the aqueous solution. After ultrasonication at 40°C and 100Hz for 6 hours, stir the solution continuously, add 1g NaCl, react at 60°C for 1 hour, and then add 0.1g NaCl 2 CO 3 , reacted at 80°C for 8h to obtain a mixture; centrifuge the reacted mixture, then dry it in a vacuum oven at 80°C, and grind it to obtain a multi-walled carbon nanotube material. Dispersion liquid, 40 ℃, 100Hz ultrasonic 2h;

[0083] (3) Tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com