Cobalt-based metal ceramic alloy powder dedicated to laser cladding of stamping die

A technology of laser cladding and stamping dies, which is applied in the field of alloy powder, can solve the problems of high cost of stamping dies, achieve the effects of prolonging service life, improving wear resistance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix 120g of silicon carbide, 3g of carbon, 40g of calcium fluoride, 40g of silicon nitride, 10g of boron, 220g of chromium, 3g of vanadium, 50g of iron, 120g of molybdenum, 10g of manganese, and 384g of cobalt to obtain 100-200 mesh cobalt-based metals Ceramic alloy powder.

Embodiment 2

[0023] Mix 140g of silicon carbide, 5g of carbon, 60g of calcium fluoride, 60g of silicon nitride, 30g of boron, 270g of chromium, 7g of vanadium, 70g of iron, 180g of molybdenum, 14g of manganese and 164g of cobalt to obtain 100-200 mesh cobalt base Cermet alloy powder.

Embodiment 3

[0025] Mix 130g of silicon carbide, 4g of carbon, 50g of calcium fluoride, 50g of silicon nitride, 20g of boron, 250g of chromium, 5g of vanadium, 60g of iron, 150g of molybdenum, 12g of manganese, and 269g of cobalt to obtain 100-200 mesh cobalt-based metals Ceramic alloy powder.

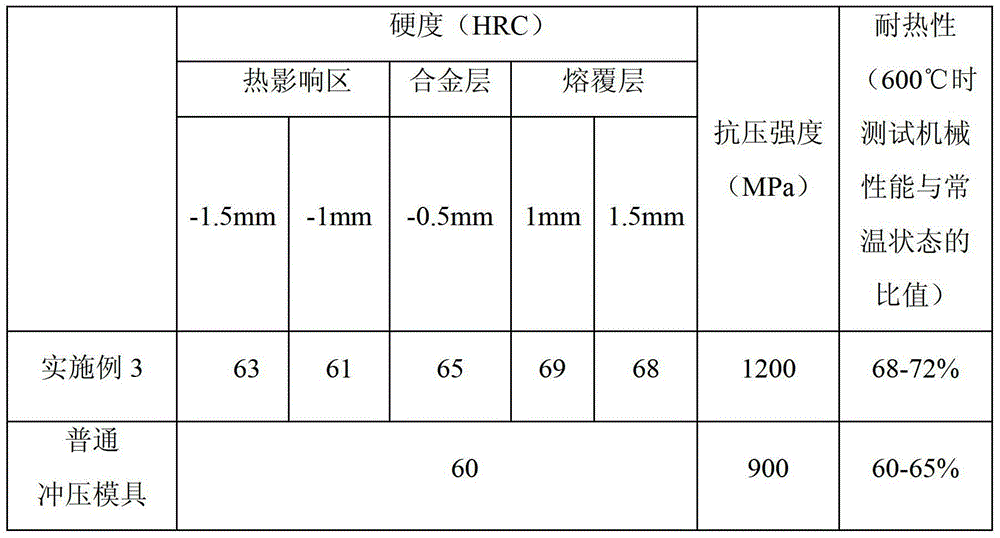

[0026] The cermet alloy powder mixed in this embodiment 3 is evenly ejected from the powder injection hole of the laser head, the powder feeding direction of the cermet alloy powder is coaxial with the laser beam, the laser wavelength of the laser is 1.06um, and the output power is 4000W , the running speed is 3m / min, and the single track width is 2mm. The parts of the stamping die that need to be laser clad are generally the working surfaces such as the shearing part of the stamping die, the forming surface, and the cavity. The stamping die obtained by laser cladding is mechanically inspected to obtain the following data: (the distance in the table below is based on the bottom surface of the clad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com