Anaerobic granular sludge expanded bed-gravity flow membrane filter sewage treatment system and method utilizing same to treat sewage

An anaerobic granular sludge and treatment system technology, applied in the field of sewage and wastewater treatment systems, can solve the problems of high energy consumption, large floor space, and poor energy recovery, and achieve low energy consumption, reduced floor space, and energy saving consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

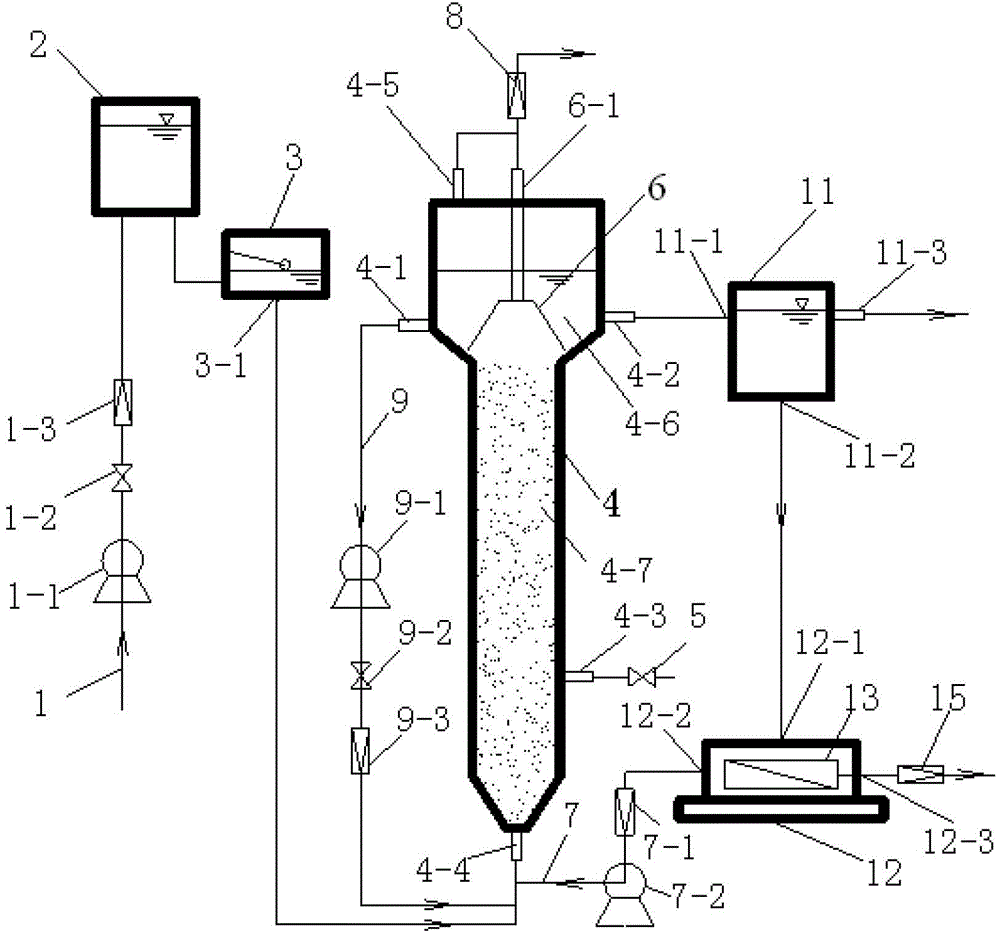

[0022] Specific Embodiment 1: In this embodiment, the sewage and wastewater treatment system of anaerobic granular sludge expanded bed-gravity flow membrane filtration consists of a water inlet pipe 1, a sewage lifting pump 1-1, a water inlet valve 1-2, and a water inlet flowmeter 1 -3. High level water tank 2. Float valve constant position device 3. Anaerobic granular sludge expanded bed 4. Sludge discharge valve 5. Three-phase separator 6. Internal circulation pipe 7. Internal circulation flow meter 7-1. Internal circulation pump 7-2. Wet flow meter 8, return pipe 9, return pump 9-1, return valve 9-2, return flow meter 9-3, constant overflow device 11, gravity flow membrane filtration device 12, membrane module 13 Composed of outlet flowmeter 15;

[0023] Among them, the water inlet pipe 1 is connected with the high-level water tank 2, and the sewage lifting pump 1-1, the water inlet valve 1-2 and the water inlet flowmeter 1-3 are arranged sequentially on the water inlet pip...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the carrier inside the anaerobic granular sludge expanded bed 4 sludge area 4-7 is powdered activated carbon, granular activated carbon or zeolite, and the particle size is controlled to be 0.1 mm ~ 2mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the material of the membrane module 13 is polyvinylidene fluoride, polyvinyl chloride, polyether sulfone, polyacrylonitrile or polypropylene ultrafiltration membrane; The diameter of the membrane hole is 0.01 μm-0.1 μm; the shape of the membrane module 13 is flat plate or hollow fiber. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com