Utilize the method for solid acid-base catalyzed synthesis of vinpocetine

A technology of acid-base catalysis and solid acid, which is applied in the chemical industry, can solve the problems of a large amount of acid-base wastewater, consume large acid-base, and environmental protection pressure, and achieve the effects of promoting esterification and dehydration reactions, good environmental protection, and promoting synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

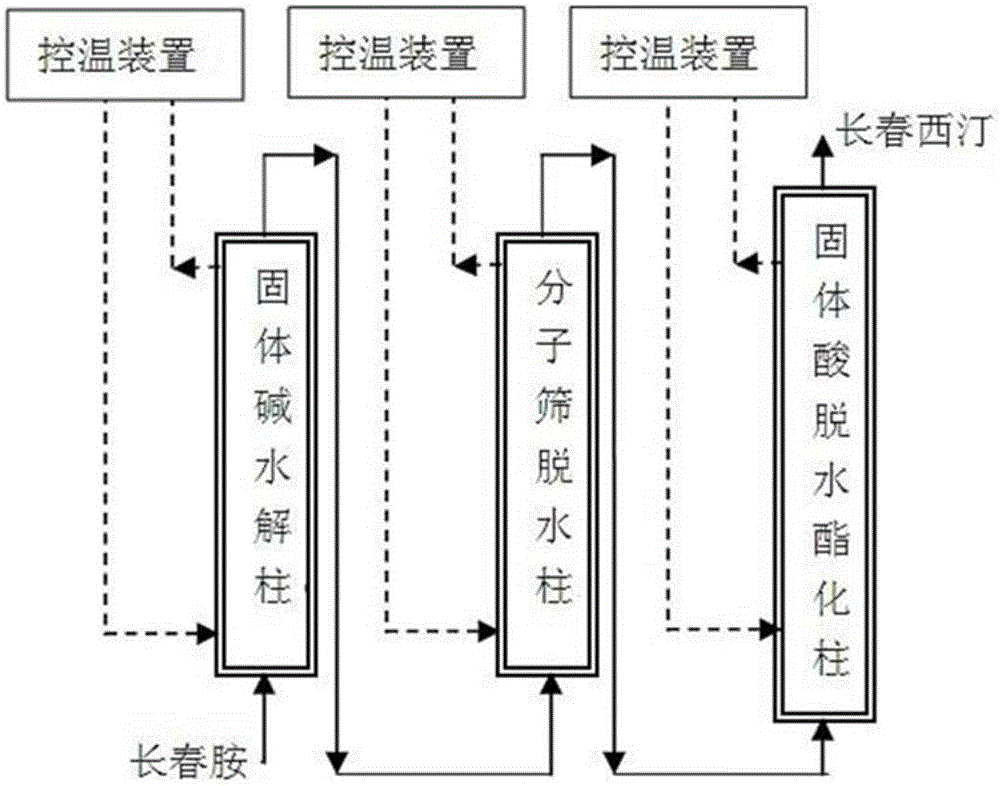

[0028] The present embodiment relates to a kind of method utilizing solid acid-base catalysis to synthesize Vinpocetine, and described method comprises the steps:

[0029] Step 1, solid alkali hydrolysis: vincamine and dehydrated alcohol are 1:10 to prepare vincamine ethanol solution by weight ratio, and described vincamine ethanol solution is sent into aluminoxomonosodium (particle size is 0.1mm) hydrolysis column for hydrolysis reaction, the column temperature is 60°C.

[0030] Step 2, molecular sieve dehydration: pass the hydrolyzed vincamine ethanol solution through a 3A molecular sieve dehydration column at a flow rate of 30 ml / hour to perform a dehydration reaction, and the column temperature is 60°C.

[0031] Step 3, dehydration and esterification of solid acid: the feed liquid after dehydration enters at a rate of 30 ml / hour to contain 1% 3A molecular sieve packing and a particle size of 0.1 mm solid acid SO 4 2- / TiO 2 -Fe 2 o 3 Fill the solid acid dehydration es...

Embodiment 2

[0035] The present embodiment relates to a kind of method utilizing solid acid-base catalysis to synthesize Vinpocetine, and described method comprises the steps:

[0036] Step 1, solid alkali hydrolysis: vincamine and dehydrated alcohol are 1:20 to prepare vincamine ethanol solution by weight ratio, and described vincamine ethanol solution is sent into aluminoxomonosodium (particle size is 2mm) hydrolysis column for hydrolysis reaction; column temperature is 180°C;

[0037] Step 2, molecular sieve dehydration: the hydrolyzed vincamine ethanol solution is passed through a 3A molecular sieve dehydration column at a flow rate of 3 liters per hour, and the column temperature is 180°C.

[0038] Step 3, dehydration and esterification of solid acid: the feed liquid after dehydration enters at a speed of 3 liters / hour to contain 10% 3A molecular sieve packing and a particle size of 2 mm solid acid SO 4 -2 / ZrO 2 Fill the solid acid dehydration esterification column with solid acid...

Embodiment 3

[0042] The present embodiment relates to a kind of method utilizing solid acid-base catalysis to synthesize Vinpocetine, and described method comprises the steps:

[0043] Step 1, solid alkali hydrolysis: vincamine and absolute ethanol are prepared vincamine ethanol solution at a weight ratio of 1:20, and the vincamine ethanol solution is fed into monosodium aluminoxide, dialuminum oxide with a flow rate of 2 liters / hour. The mixture of sodium (particle size is 1mm) is hydrolyzed on the column, and the hydrolysis reaction is carried out, and the column temperature is 100°C.

[0044] Step 2, molecular sieve dehydration: the hydrolyzed vincamine ethanol solution is passed through a 3A molecular sieve dehydration column at a flow rate of 2 liters per hour, and the column temperature is 100°C.

[0045] Step 3, dehydration and esterification of solid acid: the feed liquid after dehydration enters at a speed of 2 liters / hour to contain 20% 3A molecular sieve packing and a particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com