Preparation method and application of modified polyester stretch yarn with special-shaped section

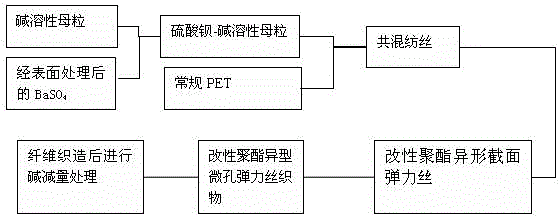

A special-shaped cross-section, modified polyester technology, applied in the field of spinning, can solve the problems of low end breakage rate, polyester fiber can not meet the moisture absorption and perspiration performance, etc., achieve low end breakage rate, good moisture absorption and perspiration effect, machine Use efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of alkali-soluble masterbatch: 16.9kg (100mol) of purified terephthalic acid (PTA), 7.13kg (115mol) of ethylene glycol (EG), 240g (2% of the molar content of ethylene glycol) 5.87g of isoprene glycol and polymerization catalyst antimony trioxide were mixed together and added to the reaction system, and esterified at 250-260°C under normal pressure. After esterification finishes, add 8mol isophthalic acid-5-sodium sulfonate, after stirring, add 2kg average molecular weight and be the polyethylene glycol (PEG) of 6000 and 1.92g antioxidant 1010, mix at the low temperature of 0.1kpa Vacuum, after pre-condensation at 270°C for 120 minutes, the temperature of the reaction system was maintained at 270°C, and the vacuum degree was 50pa for final polycondensation to obtain 22Kg of alkali-soluble masterbatches (theoretical value is 19.2kg, which is based on the fact that the polymerization product is only PET calculation). The prepared alkali-soluble masterbatch...

Embodiment 2

[0041] (1) Preparation of alkali-soluble masterbatch: 16.9kg (100mol) of purified terephthalic acid (PTA), 7.13kg (115mol) of ethylene glycol (EG), 480g (4% of the molar content of ethylene glycol) 5.76 g of isopentyl glycol and polymerization catalyst antimony trioxide were mixed together and added to the reaction system, and esterified at 250-260° C. under normal pressure. Add 8mol of isophthalic acid-5-sodium sulfonate after the esterification is finished, after stirring evenly, add 2kg of polyethylene glycol (PEG) with an average molecular weight of 8000 and add 5.70g of antioxidant 1076, mix it in a low vacuum 0.1 kpa, after pre-condensation at 260°C for 90 minutes, heat the temperature of the reaction system to 270°C, and carry out final polycondensation at a vacuum of 50pa or below to obtain an alkali-soluble masterbatch of 22.3Kg (theoretical value is 19.2kg, which is based on the polymerization Products calculated for PET only). The prepared alkali-soluble masterbatc...

Embodiment 3

[0048] (1) Preparation of alkali-soluble masterbatch: 16.9kg (100mol) of purified terephthalic acid (PTA), 7.13kg (115mol) of ethylene glycol (EG), 240g (2% of the molar content of ethylene glycol) 5.76 g of isopentyl glycol and polymerization catalyst antimony trioxide were mixed together and added to the reaction system, and esterified at 250-260° C. under normal pressure. Add 8mol of isophthalic acid-5-sodium sulfonate after the esterification is finished, stir evenly, add 2kg of polyethylene glycol (PEG) with an average molecular weight of 1000 and add 4.6g of phosphite and 5g of antioxidant 1076, mix well After pre-condensation at a low vacuum of 0.1kpa and a temperature of 280°C for 120 minutes, the temperature of the reaction system was lowered to 270°C, and the final polycondensation was carried out at a vacuum degree of 50pa or below to obtain an alkali-soluble masterbatch of 21.8Kg (theoretical value is 19.2kg, This theoretical value is calculated based on the fact t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com