Hydraulic power generation system

A technology of generators and control systems, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as not being vigorously developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

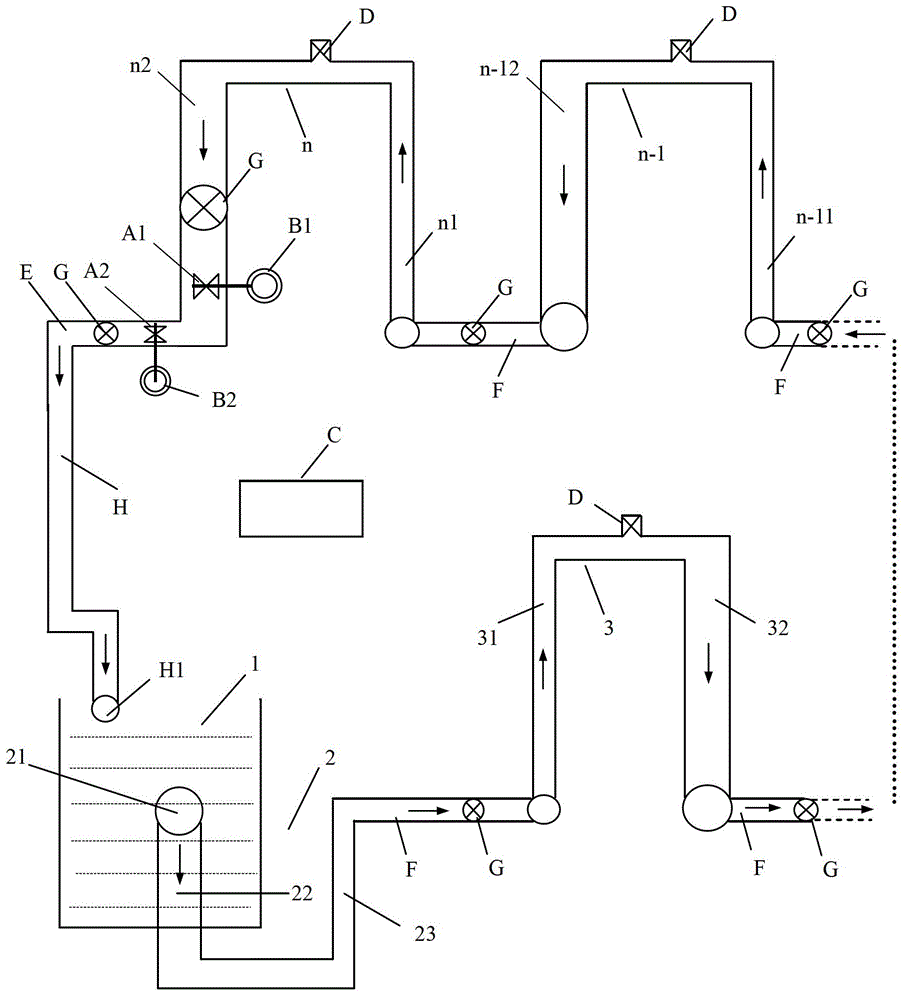

[0033] see figure 1 , the embodiment of the present invention is provided with water source 1, n-level U-shaped pipe, main water turbine A1, auxiliary water turbine A2, main generator B1, auxiliary generator B2, power transmission and control system C; The water outlet 21 is set in the water source 1 below the water surface of the water source by 2m, and the diameter of the first-stage water inlet pipe (thick pipe) 22 is larger than the diameter of the first-stage water outlet pipe (thin pipe) 23, so as to enhance the water pressure; The diameter of the second-stage water inlet pipe 31 of the second-stage U-shaped pipe 3 is smaller than the diameter of the second-stage water outlet pipe 32, which is used to convert the water pressure difference into a weight difference. By analogy, the n-level U-shaped tubes are connected in series in sequence. In addition to the U-shaped pipe 2 of the first stage, each U-shaped pipe is equipped with a water injection port D with safety press...

Embodiment 2

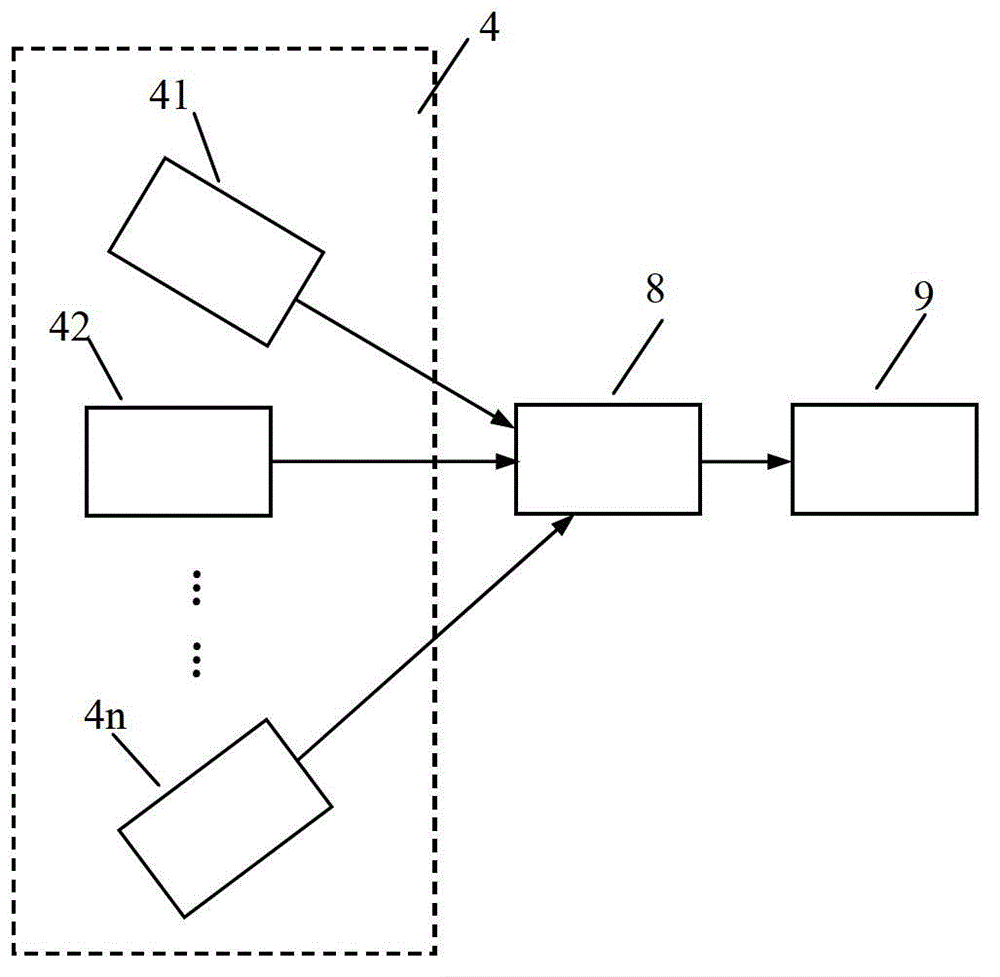

[0042] see figure 2 , similar to Embodiment 1, the difference is that n-level U-shaped tubes are connected in parallel to the frame 4 structure, and after n-level U-shaped tubes 41, 42, ..., 4n are connected in parallel, the n-level U-shaped tubes are connected in parallel The water flow in frame 4 is collected to the water flow collection pipe 8 connected in parallel with n-stage U-shaped pipes. As long as the diameter and mouth size of the n-level U-shaped pipes connected in parallel are appropriately increased, the collection of large water flows can be realized to meet the high-power power generation requirements of the power station 9; or for each U-shaped pipe in parallel Power stations 9 are respectively installed for multi-station grid-connected power generation to realize high-power power generation and power supply.

Embodiment 3

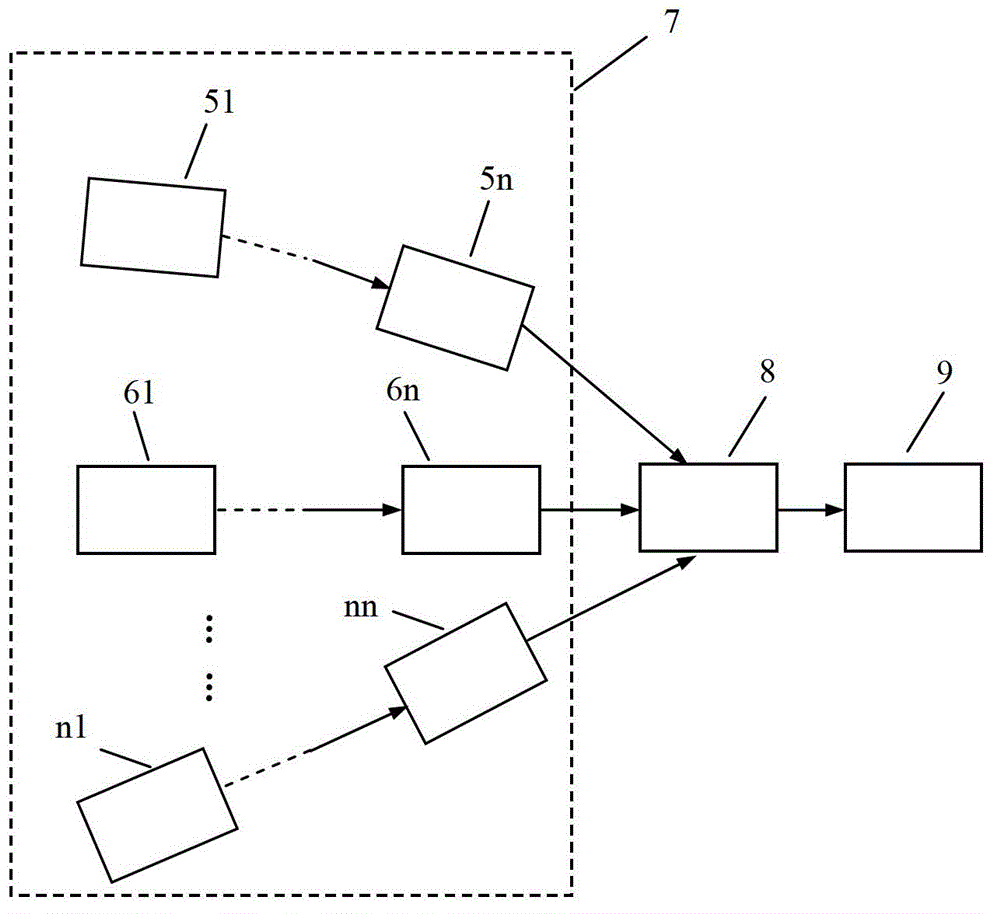

[0044] see image 3 , embodiment 3 is a combination of embodiment 2 and embodiment 1, the difference is that the n-level U-shaped tubes 51~5n, 61~6n, ..., n1~nn are arranged in a similar manner figure 1 The method for forming n-level U-shaped tubes is connected in series, and then the n-level U-shaped tubes 51~5n, 61~6n, ..., n1~nn are connected in a similar manner figure 2 The method is used to form a parallel connection to form a series structure of n-level U-shaped tubes and a parallel structure of n-level U-shaped tubes to form a mixed structure frame 7 . The water flow in the mixed structure frame 7 formed by the series structure of the n-level U-shaped tubes and the parallel structure of the n-level U-shaped tubes is collected to the water flow collection pipe 8 in which the n-level U-shaped tubes are mixed. As long as the diameter of the n-level U-shaped pipes connected in parallel is appropriately increased, the water collection pipe 8 can generate a domino effect to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com