Determination method of iron content in coating of alloying hot galvanized plate

A hot-dip galvanized sheet and alloying technology, applied in thermal excitation analysis, material excitation analysis, etc., can solve the problems of low precision and long iron content detection cycle, and achieve high accuracy, fast analysis speed, and reliable analysis data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

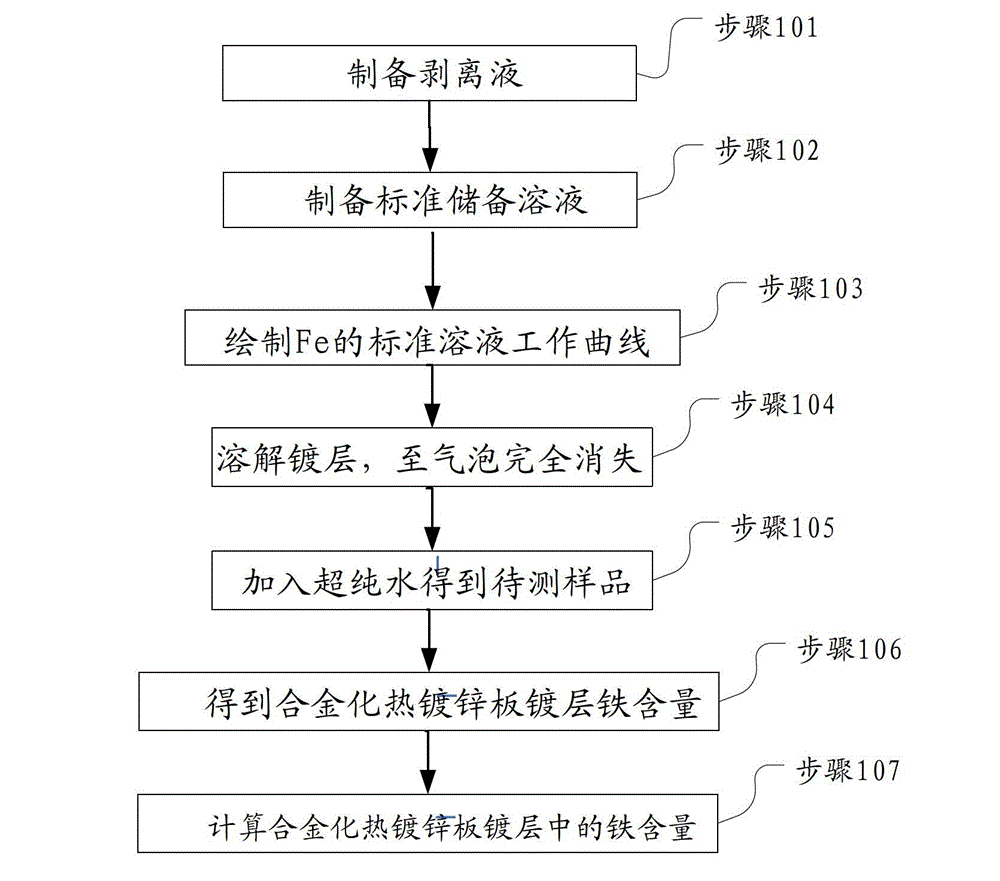

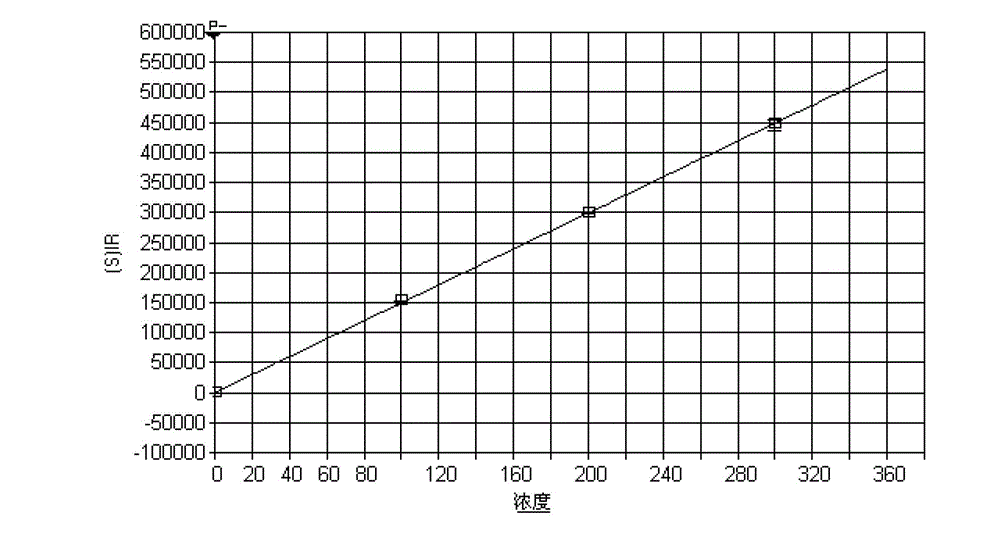

[0029] see figure 1 , a method for determining the iron content in the coating of galvanized alloyed steel sheet provided by the embodiment of the present invention uses an ICP6300 inductively coupled plasma emission spectrometer from Thermo Company of the United States, and iTEVA software (version 2.8.0.89). According to the characteristics of the sample, the setting parameters of the inductively coupled plasma emission spectrometer are determined as follows: RF high-frequency generator power 1150W, pump speed 50rpm, auxiliary gas flow 0.5L / min, flushing pump speed 50rpm, vertical observation height 15mm. The analysis wavelength used by the inductively coupled plasma atomic emission spectrometer for the standard Fe element is 259.94nm, and the number of poles is 130.

[0030] Step 101: Prepare stripping solution and prepare for analysis

[0031] Reagent preparation:

[0032] Prepare 1000ug / ml iron standard solution, hydrochloric acid with a density of 1.19g / ml, hexamethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com