III-nitride-based device structure containing multi-layer back-barrier

A device structure and back barrier technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of increasing the leakage of the buffer layer, the effect of the breakdown voltage is limited, and the composition is not too high, so as to improve the breakdown voltage, The effect of increasing the withstand voltage of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

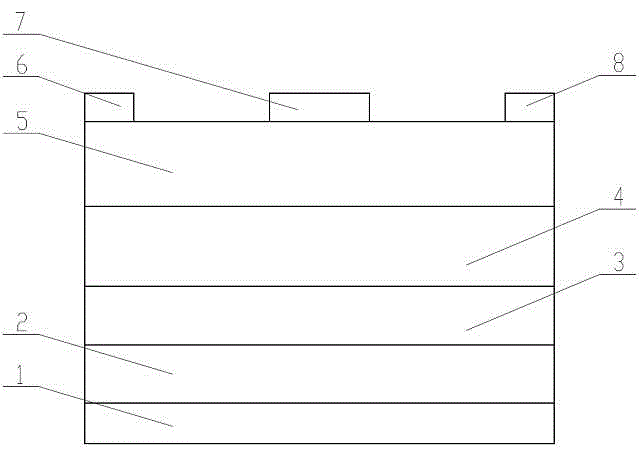

[0020] Depend on figure 1 It can be seen that Embodiment 1 is a multi-layer back barrier high electron mobility transistor HEMT based on Group III nitride materials, including a substrate layer 1, a back barrier structure layer, a channel layer 4 and a barrier layer from bottom to top 5. A source metal 6 , a gate metal 7 and a drain metal 8 are arranged on the barrier layer 5 . The back potential barrier structure layer is made up of the first back potential barrier 2 and the second back potential barrier 3, and the first back potential barrier 2 and the second back potential barrier 3 are Al x GaN (0<x<1), the Al composition in the same back barrier remains unchanged.

[0021] The substrate layer 1 is Si or sapphire; the channel layer 4 is GaN or Al x Ga 1-x N (0x al y Ga 1-x-y N (0≤x≤1, 0≤y≤1, x+y≤1).

[0022] The Al composition of the back barrier structure layer gradually increases linearly along the direction from the channel layer 4 to the substrate layer 1, that i...

Embodiment 2

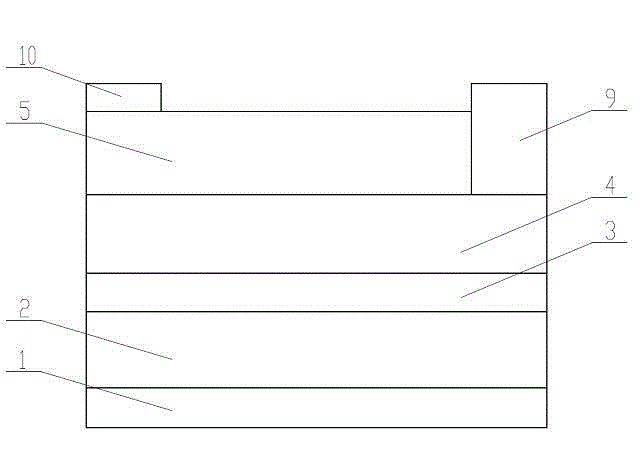

[0025] Depend on figure 2 It can be seen that Embodiment 2 is a multilayer back barrier Schottky diode SBD based on III-nitride materials, including a substrate layer 1, a back barrier structure layer, a channel layer 4 and a barrier layer 5 from bottom to top , an anode metal 10 is provided on the barrier layer 5 , and a cathode metal 9 is provided on the channel layer 4 . The back barrier structure layer is composed of a first back barrier 2 and a second back barrier 3 . The first back potential barrier 2 and the second back potential barrier 3 are Al x GaN (0<x<1), the Al composition in the same back barrier remains unchanged.

[0026] The substrate 1 is SiC or GaN or diamond; the channel layer 4 is GaN; the barrier layer 5 is In x al y Ga 1-x-y N (0≤x≤1, 0≤y≤1, x+y≤1).

[0027] The Al composition of the back barrier structure layer gradually increases nonlinearly along the direction from the channel layer 4 to the substrate layer 1 . That is, the Al composition of ...

Embodiment 3

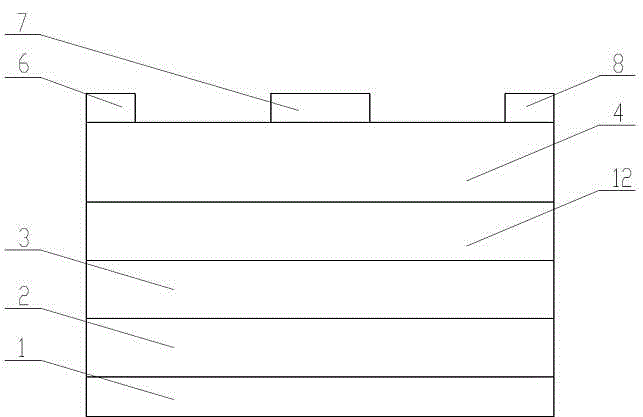

[0030] Depend on image 3 It can be seen that Embodiment 3 is a multi-layer back barrier Schottky barrier field effect transistor MESFET based on Group III nitride materials, including a substrate layer 1, a back barrier structure layer, and a channel layer 4 from bottom to top. A source metal 6 , a gate metal 7 and a drain metal 8 are disposed on the channel layer 4 . The back potential barrier structure layer is made up of the first back potential barrier 2, the second back potential barrier 3 and the third back potential barrier 12, the first back potential barrier 2, the second back potential barrier 3 and the third back potential barrier 12 for Al x GaN (0<x<1), the Al composition in the same back barrier remains unchanged.

[0031] The substrate layer 1 is Si or sapphire or SiC or GaN or diamond; the channel layer 4 is GaN or Al x Ga 1-x N (0<x<1).

[0032] The Al composition of the back barrier structure layer gradually increases nonlinearly along the direction fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com