Anti-PID effect solar cell and fabrication method thereof

A technology for solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as increasing the production cost of solar cells, and achieve the goal of eliminating PID effects, reducing production costs, and improving minority carrier life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

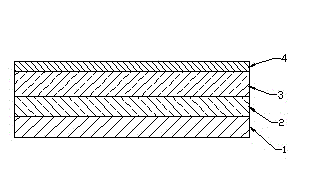

[0018] Such as figure 1 As shown, the solar cell of the present invention includes a crystalline silicon substrate 1 , and a passivation layer 2 , a light-transmitting layer 3 and an anti-PID effect layer 4 sequentially deposited on the crystalline silicon substrate. The preparation process is carried out on the tubular direct method silicon nitride coating equipment, which specifically includes the following steps:

[0019] Step 1, preheating, the crystalline silicon substrate enters the reaction chamber and is heated at a constant temperature to reach the set reaction temperature, and the temperature is set at 450°C;

[0020] Step 2, constant pressure, filling the reaction chamber with reaction gas NH 3 and SiH 4 , SiH 4 Flow 780 sccm / min, NH 3 Flow rate 3500 sccm / min, pressure range 1.7 Torr;

[0021] Step 3, passivation layer deposition, the radio frequency power is turned on, the radio frequency power is 7000 W, at the reaction temperature, the active radicals in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com