Cover planting method of biodegradable plastic film in semi-arid area

A technology for degrading plastic film and planting methods, applied in the fields of botanical equipment and methods, plant protection cover, climate change adaptation, etc., can solve the problems affecting agricultural mechanized farming, soil quality decline, threatening the health of feeding animals, etc., and achieve crop yield. and water use efficiency, increase and maintain soil water content, and reduce the effect of soil water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: a kind of covering planting method of biodegradable mulch film in semi-arid area, following steps:

[0066] (1) Field design; since the biodegradable mulch is easily broken, the coverage is required to be flat.

[0067] (2) Land preparation and ridging, and ground leveling: 7 days before crop sowing, soil preparation and ridging are carried out; the time for soil preparation, ridging and film covering is March 10-April 20; Under rainfall conditions, the initial runoff efficiency of the soil ridge was 8‐10%, and after one year of rainfall erosion and the formation of soil crusts, the runoff efficiency of the soil ridge was 20‐38%.

[0068] (3) Fertilization: Superphosphate 350‐420kg hm ‐2 and urea 220‐300kg hm ‐2 As a base fertilizer, the two kinds of fertilizers are mixed and sprinkled on the soil surface before sowing, and then poured into the soil, and the fertilization depth is 20-30cm; it is not allowed to mix crop seeds and urea to avoid burning see...

Embodiment 2

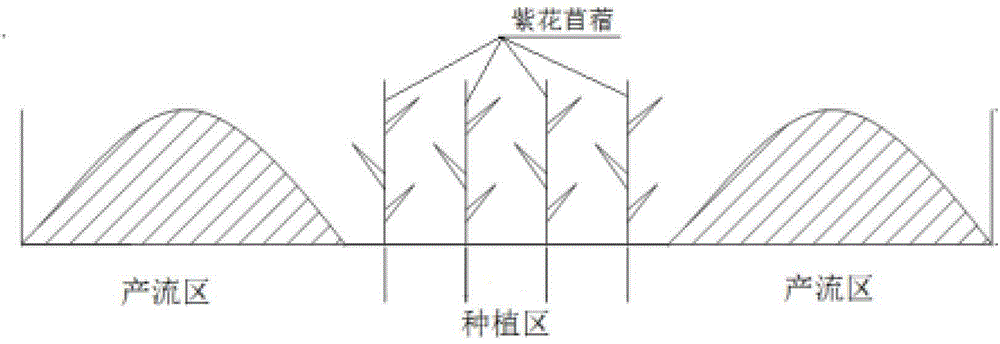

[0085] Embodiment 2: The method of covering planting (full coverage of furrows and ridges) of biodegradable plastic film in the semi-arid area also includes the following steps:

[0086] The step 1) field design, designing the micro-topography between large ridges and small ridges in the field;

[0087] Step 2) Arranging the land and raising the ridge; the width and height of the large ridge are 60-70cm and 20-25cm respectively, the angle between the ridge surface and the ground is 40-45°, and the top of the ridge is arc-shaped; the width and height of the small ridge 40-50cm and 10-15cm respectively, the angle between the ridge surface and the ground is 35-40°, and the top of the ridge is arc-shaped;

[0088] Step 3) Covering with biodegradable plastic film, after the ridges are raised, compact the soil ridges with tools (shovels) to make the width and height of the soil ridges meet the requirements, and then cover the soil with a biodegradable plastic film with a width of 14...

Embodiment 3

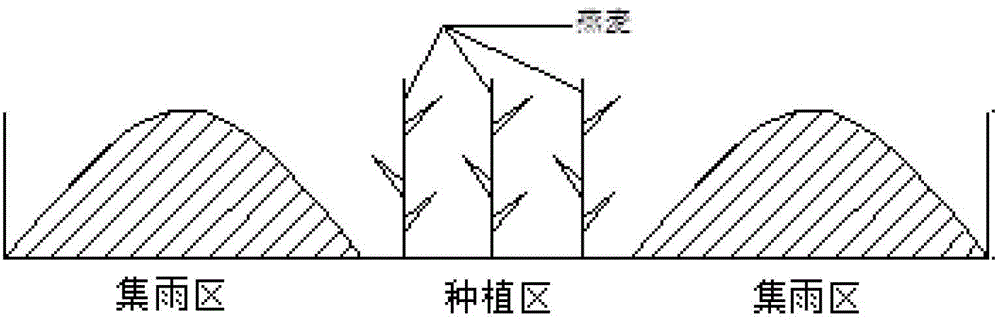

[0091] Embodiment 3: The method for covering planting of biodegradable plastic film in the semi-arid area (covering planting with combination of furrows and ridges) also includes the following steps:

[0092] The step 1) field design, design the micro-topography of furrows and ridges in the field;

[0093] Described step 2) tidy up the land and ridging; the width and height of the ridge are 40-50cm and 15-20cm respectively, and the width of the ditch is 57-63cm; The width and height meet the requirements of step 1);

[0094] In step 3) planting, the crop seeds are sown into the ditch, and the ditch is evenly covered with wheat straw after the crop is sown, and the wheat straw is cut into 3-5cm long fragments, which are evenly covered in the ditch at one time. 7500‐8000kghm ‐2 , then sprinkle 4000‐5000kg hm ‐2 Cover the stalks with crushed soil to prevent the stalks from being blown away by the wind. After harvesting, plow the stalks into the soil at a depth of 20-30cm;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com