Artificial board hot-pressing fast constant-temperature control device and method

A constant temperature control and control device technology, which is applied in the direction of temperature control using electric methods, flat products, household components, etc., can solve problems such as difficult constant temperature control and slow temperature change, achieve rapid cooling, uniform temperature distribution, and shorten heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

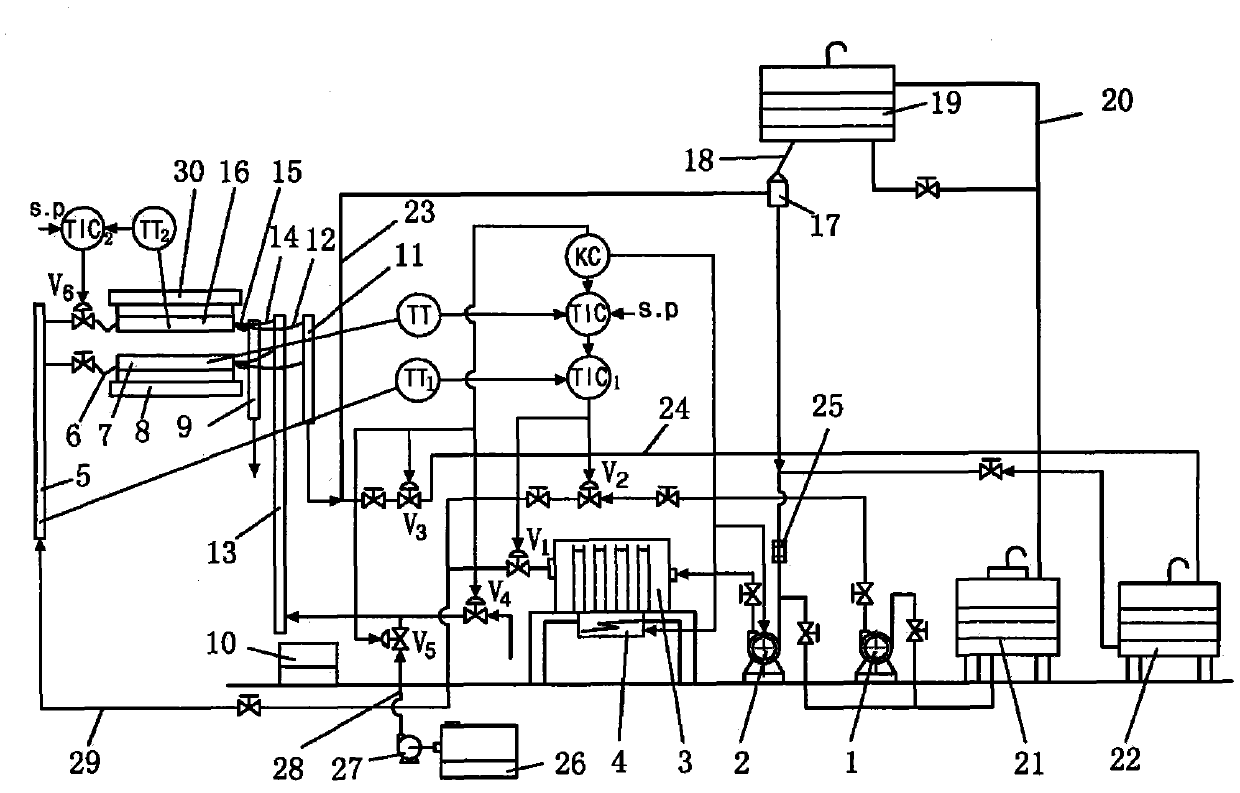

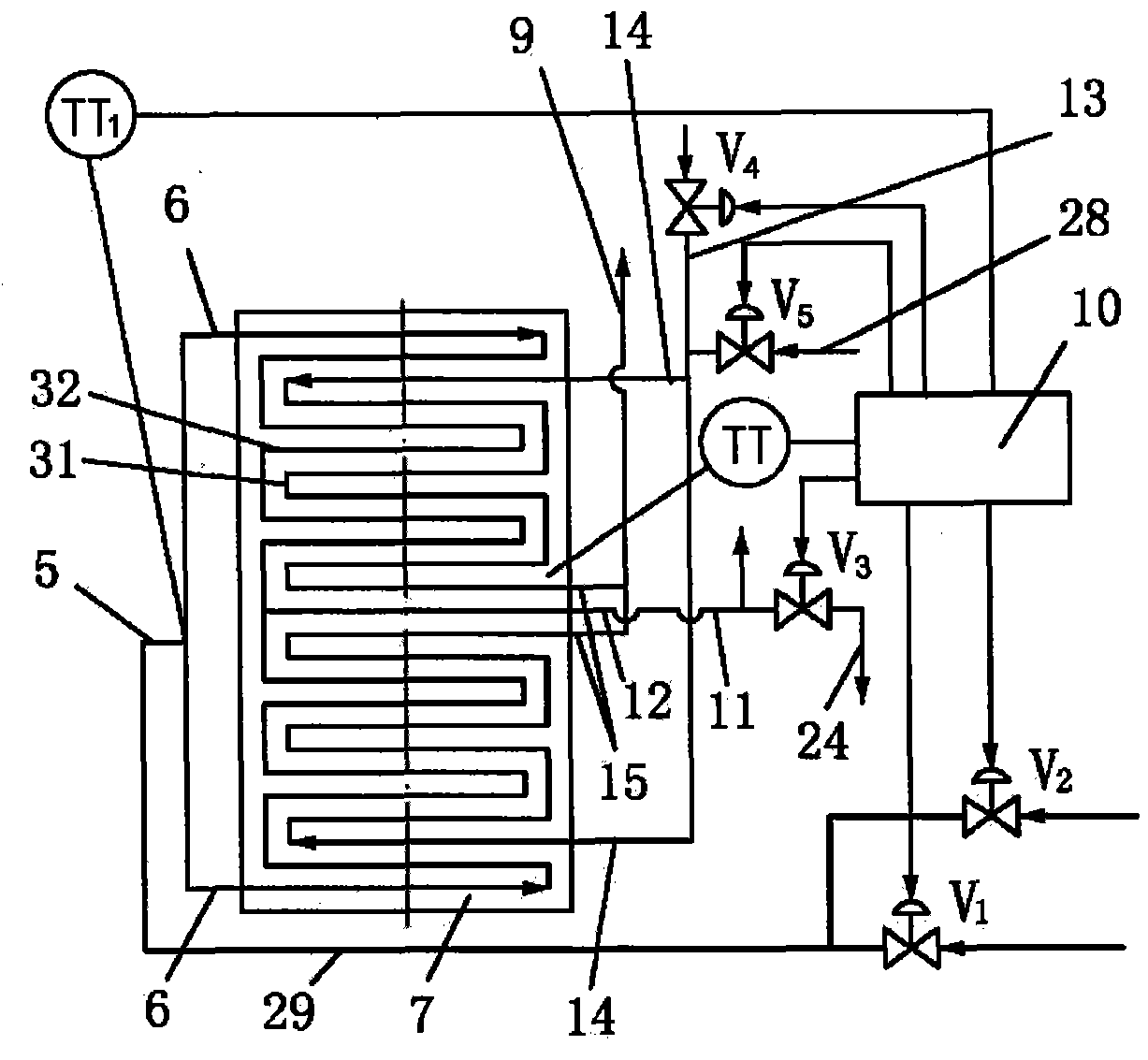

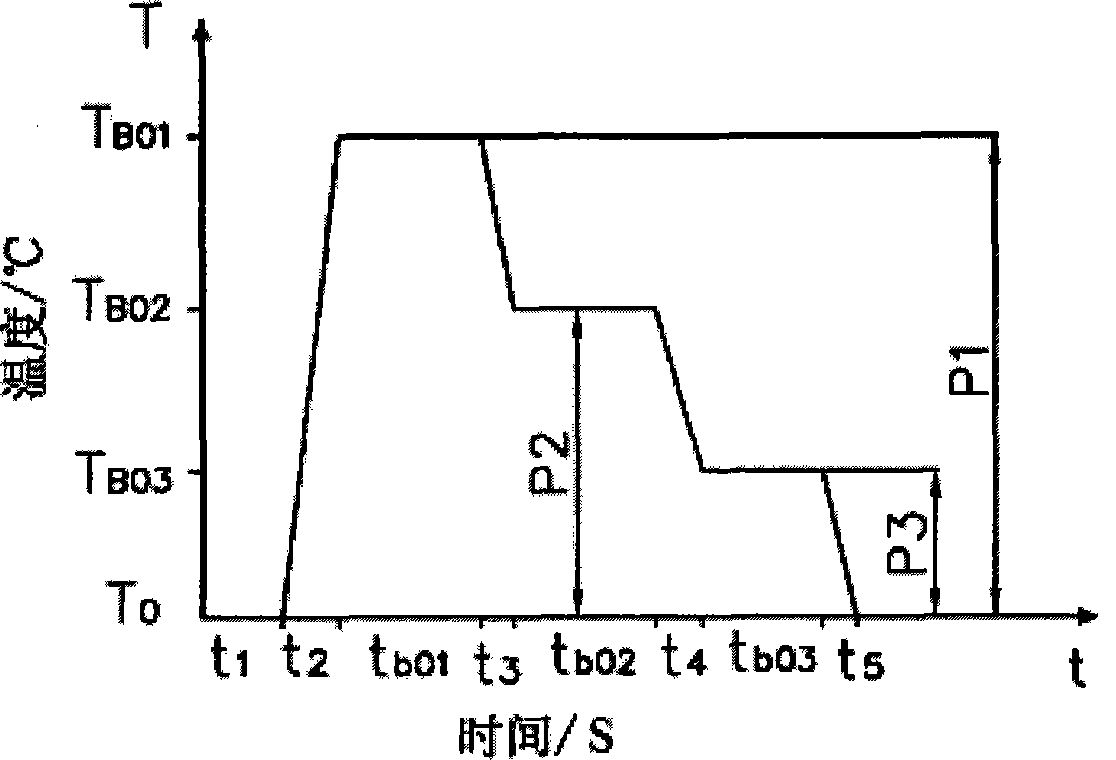

[0017] like figure 1 , 2 As shown, according to the manufacturing and installation procedures of the wood-based panel hot-pressing rapid constant temperature control device, the control device in the heat carrier circulation pipeline system is manufactured and installed, and the control device is manufactured and installed according to the image 3 As shown, taking the hot pressing process corresponding to the typical three-stage depressurization and cooling curve suitable for three boards (plywood, particle board and medium density fiberboard) in wood-based panels as an example, the above-mentioned wood-based board hot-pressing rapid constant temperature control device and control are described in detail. method implementation. according to image 3 Set the hot-pressing process parameters as shown, turn on the power, and close the hot-pressing plate. according to Figure 4 Start hot oil pump b(2), valve V 1 , V 6 Fully open, the heater (4) is energized, and the heat tra...

Embodiment 2

[0019] According to Example 1, in the heat preservation and pressure maintenance process stage, in order to keep the temperature of the hot platen constant quickly, the valve V 1 , V 2 The opening change is detected by real-time temperature T B(i+1) The process setting value T B0(i+1) and its variation range T B0(i+1) ±ΔT B OK, ΔT B is the temperature fluctuation amplitude allowed by the process. When T B(i+1) B0(i+1) -ΔT B When the valve V 1 Open large, valve V 2 Turn down and continue to heat; when T B(i+1) >T B0(i+1) +ΔT B When the valve V 1 closed, the valve V 2 Open big; V 1 , V 2 The change value of the valve opening is the flow change value of the valve and the real-time measured temperature T B(i+1) with its process setting value T B0(i+1) The difference (T B(i+1) -T B0(i+1) Change according to PID rule. The temperature of the upper hot platen (16) is controlled by the control valve V 6 A change in valve opening that passes through the valve V 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com