Preparation method of three-dimensional hollow ultralight structure carbon material and magnetic carbon composite material

A three-dimensional hollow and composite material technology is applied in the field of preparation of carbon materials and magnetic carbon composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

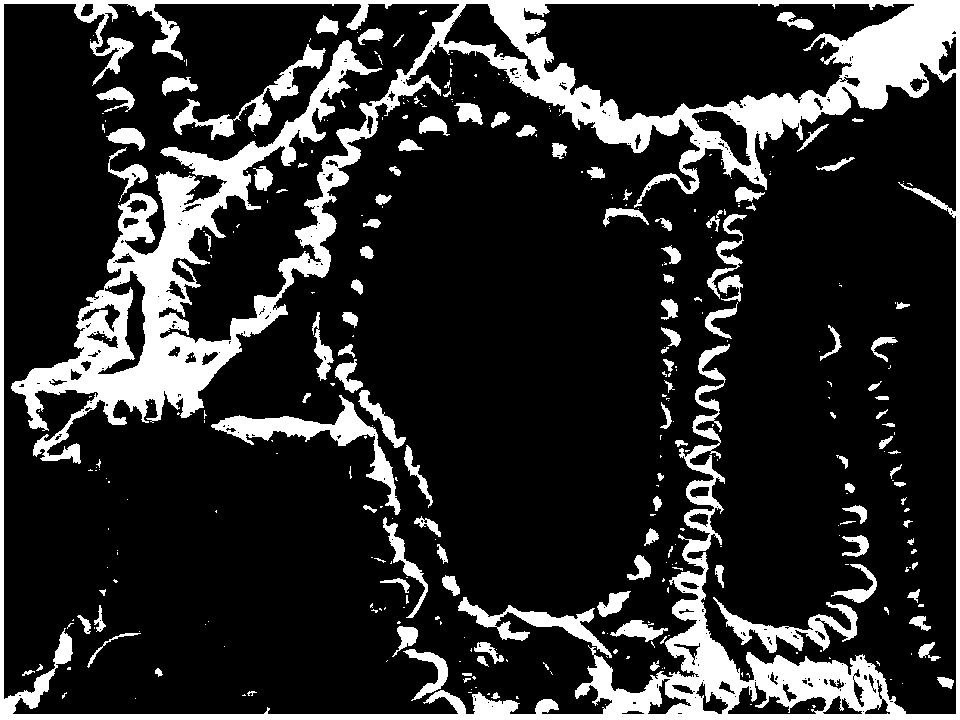

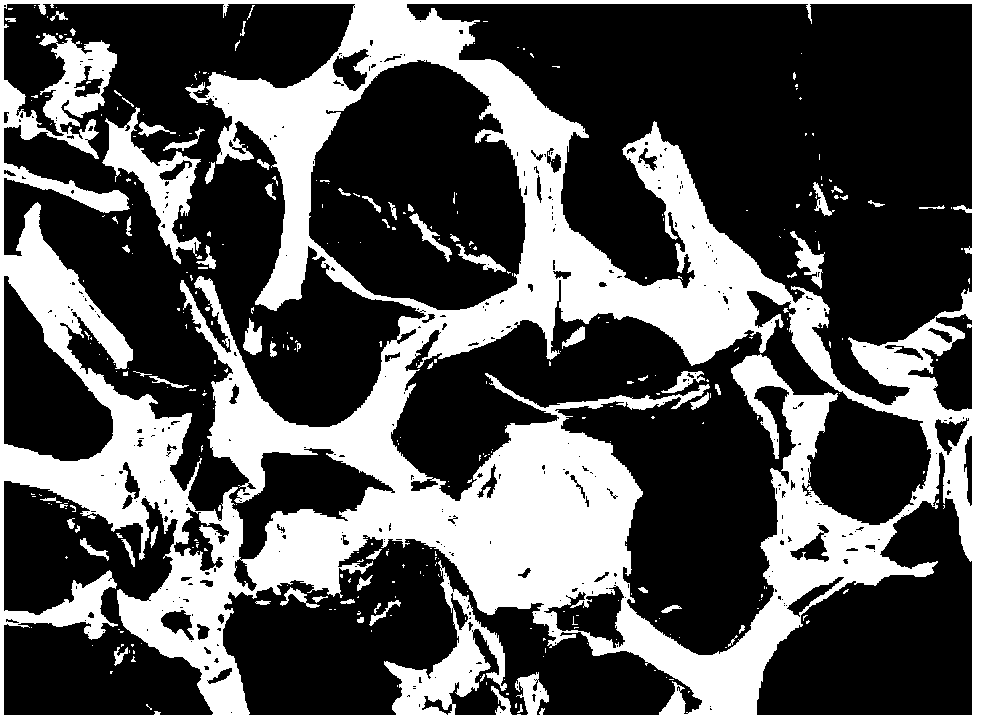

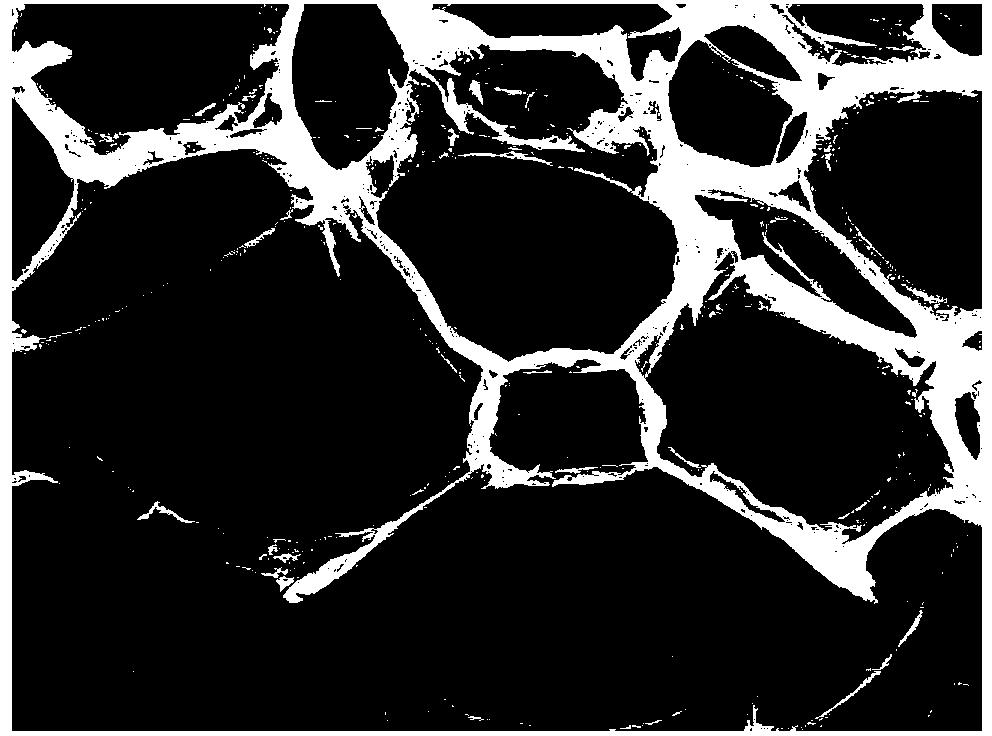

[0025] Specific implementation mode 1: The preparation method of the three-dimensional hollow ultra-light structural carbon material and magnetic carbon composite material in this embodiment is carried out according to the following steps:

[0026] One, prepare grafted polyacrylic acid polyurethane sponge;

[0027] 2. Immerse the grafted polyacrylic acid polyurethane sponge in the electrolyte solution with a concentration of 0.001mol / L~2mol / L for 10s~48h. Sintering at a temperature of 30min to 120h, the three-dimensional hollow ultra-light structure carbon material and magnetic carbon composite material can be obtained;

[0028] The polyurethane sponge described in step 1 is polyether polyurethane or polyester polyurethane;

[0029] The electrolyte solution described in step 2 is ammonium nitrate solution, ammonium acetate solution, ferric acetate solution, ferrous acetate solution, cobalt nitrate solution, cobalt acetate solution, nickel nitrate solution, ferric nitrate solu...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 2, the grafted polyacrylic polyurethane sponge is immersed in an electrolyte solution with a concentration of 0.01 mol / L-1.9 mol / L, and the soaking time is 1 min-40 h. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the grafted polyacrylic polyurethane sponge is immersed in an electrolyte solution with a concentration of 0.1 mol / L for 20 hours. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com