Reaction diffusion connecting method of superhard material aluminum magnesium boron-titanium diboride and metal

A superhard material, titanium diboride technology, applied in the field of reaction diffusion connection between superhard materials and metal materials, can solve the problems of complex process, low connection strength, low production efficiency, etc., achieve easy diffusion and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

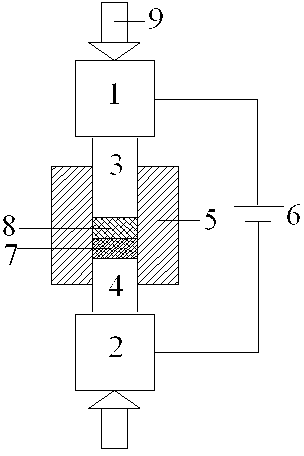

Embodiment approach 1

[0020] The thickness of the Nb plate is 3mm, the mixed powder Mg powder, Al powder and B powder are mixed at an atomic percentage of 1:1:14, and 20% by weight of TiB is added 2 Powder, the mixed powder and Nb plate are pressed into shape by mechanical pressure. according to figure 1 Place the sample in the graphite mold between the electrodes in the manner shown, raise the current to 1300A and keep it for 20min, raise the temperature of the sample to 1400°C, adjust the current and keep it warm for 10min, and finally turn off the power, and the sample is cooled to room temperature with the furnace . The vacuum degree in the furnace during the whole process is about 2×10 -3 Pa, apply a unidirectional pressure of 30MPa, take out the sample from the mold after natural cooling, superhard material AlMgB 14 -TiB 2 The hardness is 3801HV1.0.

[0021] Embodiment 2: (AlMgB 14 -TiB 2 )-Mo linking structure

Embodiment approach 2

[0022] The thickness of the Mo board is 3mm, the mixed powder Mg powder, Al powder and B powder are mixed in a molar percentage of 1:1:14, and 30% TiB is added 2 Powder, the mixed powder and Mo plate are pressed into shape by mechanical pressure. according to figure 1 Place the sample in the graphite mold between the electrodes in the manner shown, increase the current to 1500A and keep it for 20 minutes, raise the temperature of the sample to 1600°C, adjust the current for 5 minutes, and finally turn off the power, and the sample is cooled to room temperature with the furnace . The vacuum degree in the furnace during the whole process is about 2×10 -3 Pa, apply a unidirectional pressure of 60MPa, take out the sample from the mold after natural cooling, superhard material AlMgB 14 -TiB 2 The hardness is 3778HV1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com