Preparation method of molybdenum separation resin

A resin and synthetic resin technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of molybdenum loss, poor fastness of extraction color layer, etc., and achieve the effect of stable structure, good fastness and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

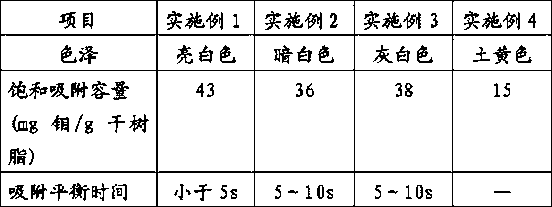

Examples

Embodiment 1

[0022] (1) Prepare dispersant solution: add 0.8g dispersant (polyvinyl alcohol) into 50mL deionized water under stirring, raise the temperature to 50°C to completely dissolve the dispersant, and obtain a dispersant solution;

[0023] (2) Prepare the organic phase containing α-benzoin oxime: add 1g of α-benzoin oxime to 25mL organic solvent mixture of acetone and chloroform (2:1 volume ratio), stir to dissolve α-benzoin oxime, then add 0.1g Tackifier polystyrene, ultrasonically dispersed for 30-40 minutes to obtain an organic phase containing α-benzoin oxime;

[0024] (3) Preparation of styrene-divinylbenzene prepolymer: Mix 40g of styrene, 10g of divinylbenzene and 2g of initiator (dibenzoyl peroxide), stir evenly, heat up to 65-70°C, and make The reactant undergoes a prepolymerization reaction for 30-40 minutes to obtain a styrene-divinylbenzene prepolymer;

[0025] (4) Synthetic resin: Add 50mL of the styrene-divinylbenzene prepolymer obtained in step (3) into 50mL of the d...

Embodiment 2

[0027] Preparation method is the same as embodiment 1, and difference is:

[0028] In the dispersant solution of step (1), oxidized polyvinyl alcohol is used as the dispersant; in step (2), 25 mL of ethyl acetate and acetone (2:1 by volume) are used as organic solvents to dissolve 1 g of α-benzoin oxime, a tackifier Polystyrene is adopted; in the step (3), dibenzoyl peroxide is used as an initiator, and in the step (4), the styrene-divinylbenzene prepolymer, the dispersant solution and the organic phase containing α-benzoin oxime The volumes are 50 mL, 50 mL and 30 mL respectively, and the reaction temperature of the styrene-divinylbenzene prepolymer and the organic phase containing α-benzoin oxime is 85° C. for 15 hours.

Embodiment 3

[0030] Preparation method is the same as embodiment 1, and difference is:

[0031] In the dispersant solution of step (1), polymaleic acid is used as a dispersant; in the organic phase of step (2), ethanol and acetone are used as organic solvents to dissolve α-benzoin oxime, and the tackifier is polyethylene glycol distearic acid Esters; in step (3), potassium persulfate is used as the initiator, and the volumes of the styrene-divinylbenzene prepolymer, the dispersant solution and the organic phase containing α-benzoin oxime in the step (4) are 50mL and 50mL respectively , 30 mL, and the reaction temperature of the styrene-divinylbenzene prepolymer and the extract phase containing α-benzoin oxime is 85° C., and the reaction time is 15 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com