Yellow ceramic ink for ink-jet printing

An inkjet printing, ceramic ink technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of wear, printer nozzle blockage, etc., to achieve good decorative effect, less sedimentation, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

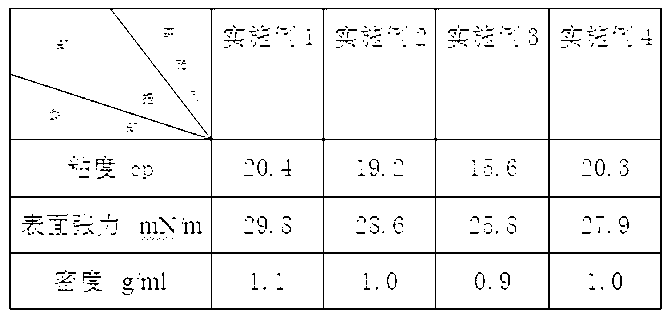

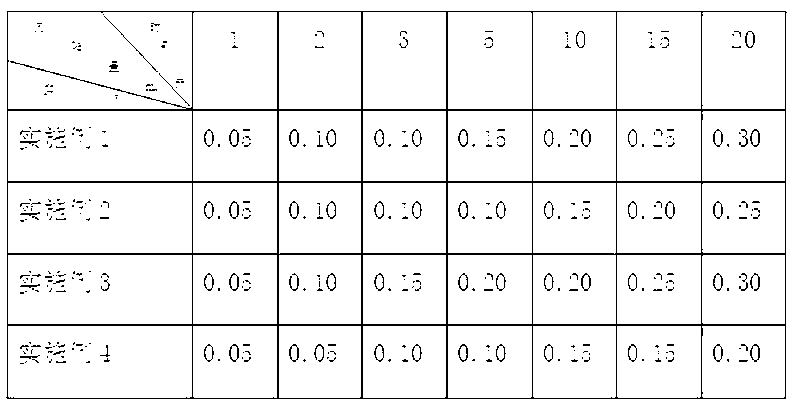

Embodiment 1

[0022] (1) Add 0.5ml oleylamine to 2ml cyclopentane, undecane, petroleum ether mixture and mix evenly, then take 0.4ml mixture and add 2g Pr / ZrSiO 4 , put it into a ball mill tank for ball milling modification for 1h.

[0023] (2) Take 1ml polyethylene glycol stearate and add 10ml cyclopentane, undecane, petroleum ether mixture and mix evenly, then add ball milled modified Pr / ZrSiO 4 In the process, the ceramic ink was obtained after ball milling for 4 hours, and it was placed in a 5ml graduated test tube to observe its sedimentation.

Embodiment 2

[0025] (1) Mix 1ml of deionized water and 9ml of absolute ethanol evenly, adjust the pH to 4.0 with acetic acid, then add 2.5ml of silane coupling agent for hydrolysis for 30min, then take 5ml of the mixture and add 1.5g of Pr / ZrSiO 4 Put it into a ball mill tank for ball milling for 40 minutes, and then put it in an oven at 90°C for 2 hours.

[0026] (2) Mix 9ml dodecane, octane, white oil mixture with 1ml hexanol, then add 1ml lauryl polyethylene glycol ester and mix evenly, then add ball milled modified Pr / ZrSiO 4 In the process, the ceramic ink was obtained after ball milling for 4 hours, and it was placed in a 5ml graduated test tube to observe its sedimentation.

Embodiment 3

[0028] (1) Mix 1ml of deionized water and 9ml of absolute ethanol evenly, adjust the pH to 4.0 with acetic acid, then add 2.5ml of silane coupling agent to hydrolyze for 30min, then take 5ml of the hydrolyzed solution and add 1.5g of Pr / ZrSiO 4 Put it into a ball mill tank for ball milling for 40 minutes, and then put it in an oven at 90°C for 2 hours.

[0029] (2) Add the mixture of 0.5ml nonylphenol polyoxyethylene ether and 0.5ml cocoamine polyoxyethylene ether to the mixture of 10ml absolute ethanol, 1,2-diphenylethane and petroleum ether and mix evenly. Then add ball-milled modified Pr / ZrSiO 4 In the process, the ceramic ink was obtained after ball milling for 4 hours, and it was placed in a 5ml graduated test tube to observe its sedimentation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com