Elastic thermal insulating coating

A thermal insulation coating and elastic thermal insulation technology, applied in the direction of reflection/signal coating, coating, etc., can solve the problems of poor thermal insulation effect, inability to balance thermal insulation performance, water resistance and weather resistance, poor weather resistance, etc., to achieve good environmental friendliness Performance, excellent thermal insulation effect, excellent weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is described in detail:

[0018] All components are commercially available.

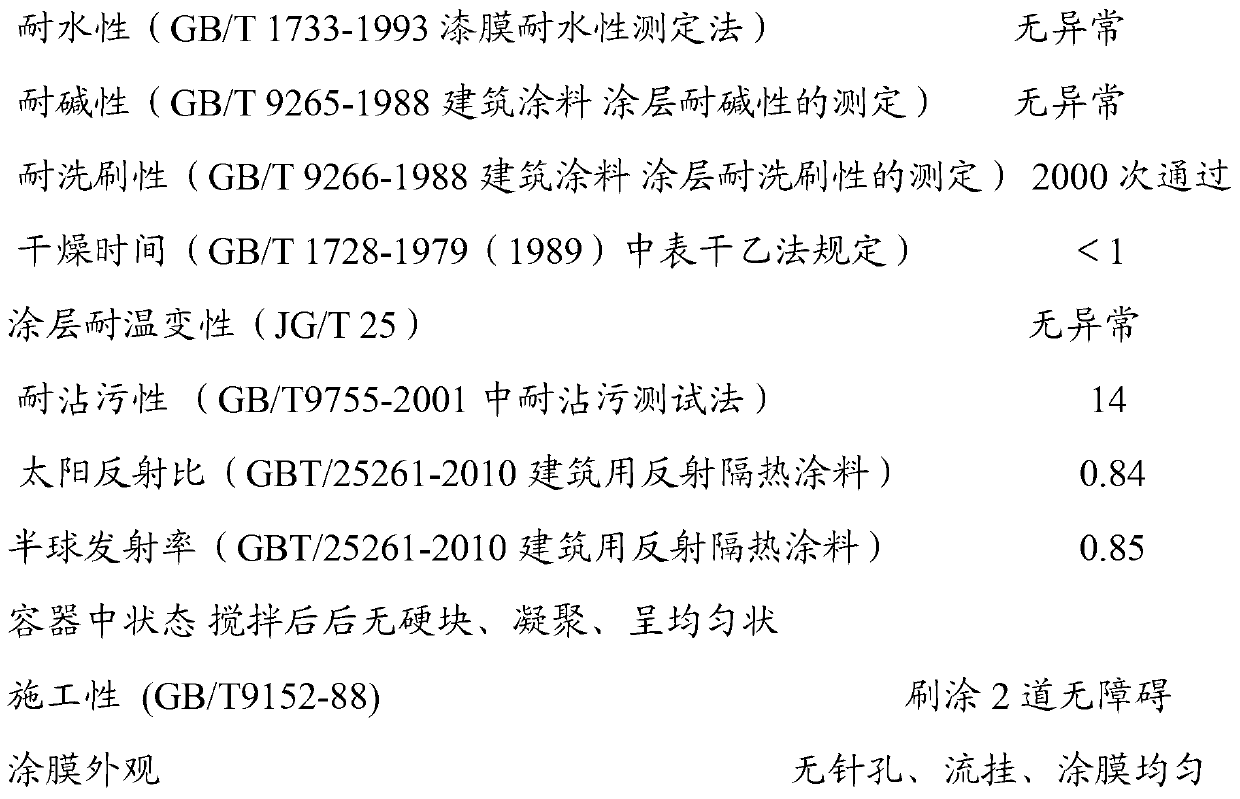

[0019] The elastic thermal insulation coating of the present invention comprises the following components by weight percentage: 45% of acrylic acid emulsion, 18% of rutile nano-titanium dioxide, 8% of hollow glass microspheres, 5% of barium sulfate, 4.5% of polystyrene Ammonium carboxylate, 2.8% low molecular weight alkylene oxide copolymer, 2.5% propylene glycol butyl ether, 0.1% hydroxyethyl cellulose, 0.4% acrylic acid-methacrylic acid copolymer, 0.3% mineral oil and 13.4% water, the particle size of the hollow glass microspheres is 10-125 μm.

[0020] First put water, hydroxyethyl cellulose, polycarboxylate ammonium salt and low molecular weight alkylene oxide copolymer into the tank, stir and disperse evenly, then add rutile nano-titanium dioxide and barium sulfate to fully disperse, and then through horizontal Grinding with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com