High-strength cast iron short-flow quick self-purification smelting technology

A high-strength, self-purifying technology, applied in the field of cast iron production, can solve problems such as the fact that the genetic influence of blast furnace molten iron has not been fundamentally eliminated, the short process of cast iron lacks a solidification link, and the deterioration of graphite morphology and mechanical properties, etc., to achieve the extension of effective incubation time , The effect of saving and reducing emissions is outstanding, and the process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A short-process smelting rapid self-purification smelting technology for high-strength cast iron. The main equipment used are: 130 cubic blast furnace, 5-ton medium-frequency induction furnace, and molten iron state analyzer. Its specific smelting process is:

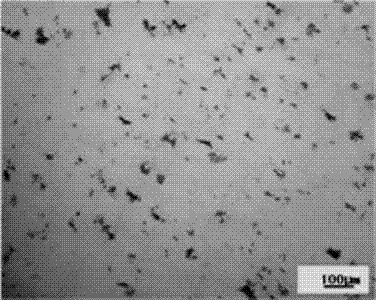

[0037](1) Load the molten iron into the blast furnace and raise the temperature according to the capacity of the intermediate frequency electric furnace, put 100% (parts by weight) of the molten iron into the blast furnace, add 0.3% 65FeMn to adjust the composition, and send electricity to raise the temperature; The holding time is 10 minutes, and the state of molten iron is judged by the rapid molten iron state analyzer in front of the furnace; (3) Inoculation treatment is carried out by SiCaBa alloy, and the addition amount is controlled at 0.6-0.8%, and then the casting is poured. High-strength cast iron with A-type graphite mainly, pearlite reaching 94%, and tensile strength above 250MPa can be obtained.

Embodiment 2

[0039] The equipment adopted in the present embodiment is identical with embodiment 1, and its concrete smelting process is:

[0040] (1) The blast furnace molten iron is loaded and heated up according to the capacity of the intermediate frequency electric furnace, and 90% (by weight) of the blast furnace molten iron is loaded, and 10% (by weight) of scrap steel and 0.4% 65FeMn are added to adjust the composition, and the temperature is raised by power transmission; (2) The molten iron is rapidly purified and smelted Superheat to the self-boiling temperature of 1515°C, hold for 9 minutes, and determine the state of molten iron with a fast molten iron state analyzer in front of the furnace; (3) Inoculation treatment Use SiCaBa alloy for inoculation treatment, the addition amount is controlled at 0.6-0.8%, and then pour the casting. High-strength cast iron with A-type graphite mainly, pearlite reaching 95%, and tensile strength above 270MPa can be obtained.

Embodiment 3

[0042] The equipment adopted in the present embodiment is identical with embodiment 1, and its concrete smelting process is:

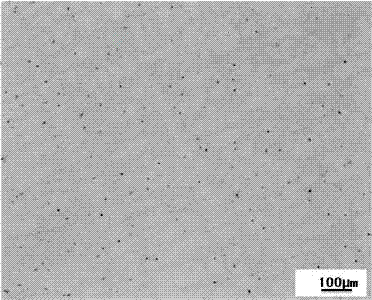

[0043] (1) The blast furnace molten iron is charged and heated up according to the capacity of the intermediate frequency electric furnace, and 85% (weight parts) of the blast furnace molten iron is loaded, and 15% (weight part) of scrap steel and 0.5% 65FeMn are added to adjust the composition, and the temperature is raised by power transmission; (2) The molten iron is rapidly purified and smelted Superheat to the self-boiling temperature of 1520°C, hold for 8 minutes, and determine the state of molten iron with a fast molten iron state analyzer in front of the furnace; (3) Inoculation treatment Use SiCaBa alloy for inoculation treatment, the addition amount is controlled at 0.6-0.8%, and then pour the casting. High-strength cast iron with A-type graphite mainly, pearlite reaching 96%, and tensile strength above 290MPa can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com