Method for adding trace elements during preparation of composite lead-free solder

A technology of lead-free solder and trace elements, which is applied in the field of materials, can solve the problems of harsh addition methods, poor wettability, and unsuitability for industrial production promotion and application, and achieve the effect of reducing processing costs and ensuring the effect of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Based on the above considerations, we have invented this addition method through a large number of experimental attempts and data analysis. Through this addition method, the pure active metal element lanthanum powder in the air atmosphere is successfully added into the brazing filler metal to obtain the same melting temperature as that of vacuum smelting. Compound composition and distribution.

[0036] The method specifically includes the following steps (taking adding highly active pure rare earth lanthanum powder to SnAgCu0307 as an example, the steps of metal elements in other component solders are similar):

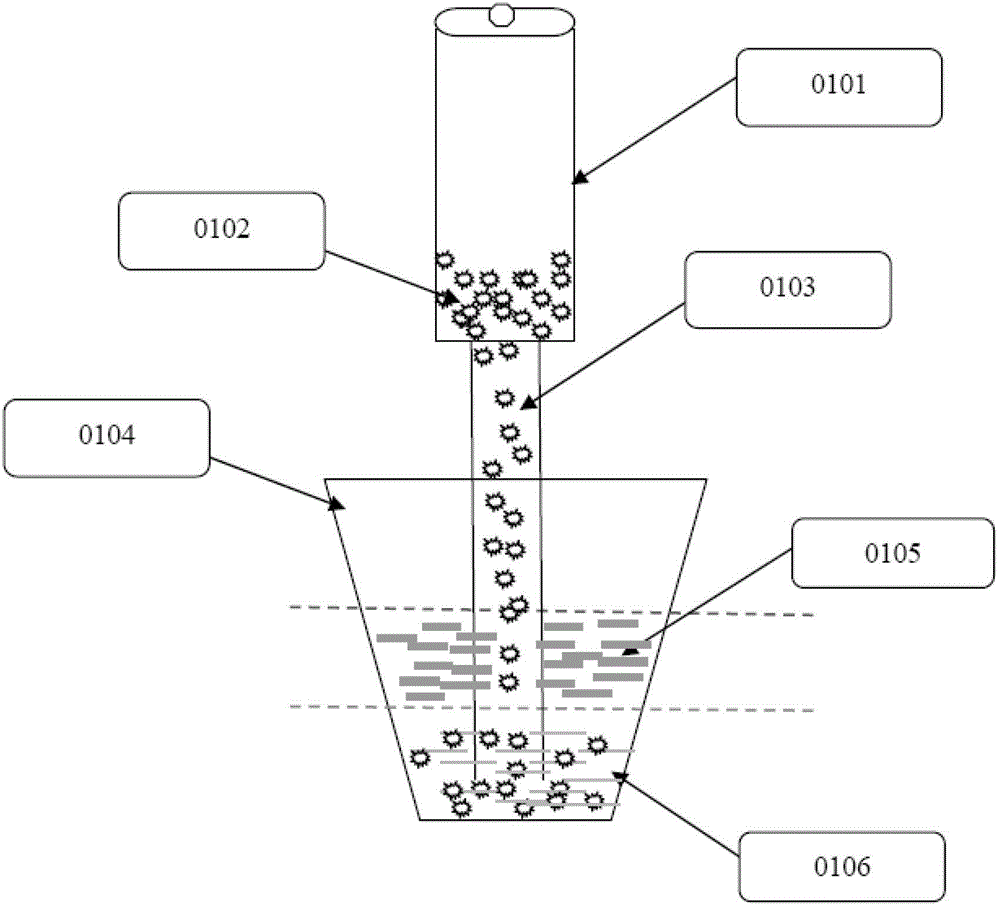

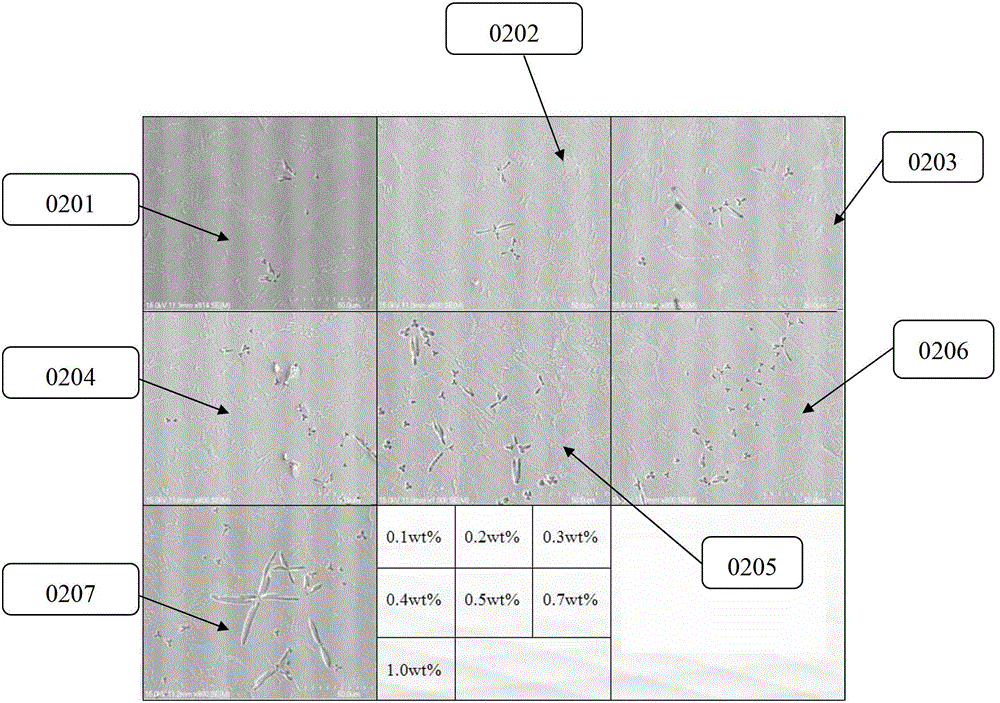

[0037] according to figure 1 and 2 (1), seven groups of composite lead-free solder SnAgCu0307 (0106) weighing 30g are used as the experimental base material, seven parts of anti-oxidation protection salt KCl are weighed, each part of 2.6g; seven parts of LiCl salt, each part of 2g (0105 ). Mix the two salts and cover the previous composite lead-free solder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com