Oscillating-type heating drying system and method used for blanks

A heating and drying, oscillating technology, applied in the direction of heating devices, drying gas arrangement, lighting and heating equipment, etc., can solve the problems of prolonged drying time, cracking, and umbrella drop of electric porcelain insulators, so as to reduce the drying cycle and energy consumption, increase Loading volume, effect of reducing manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

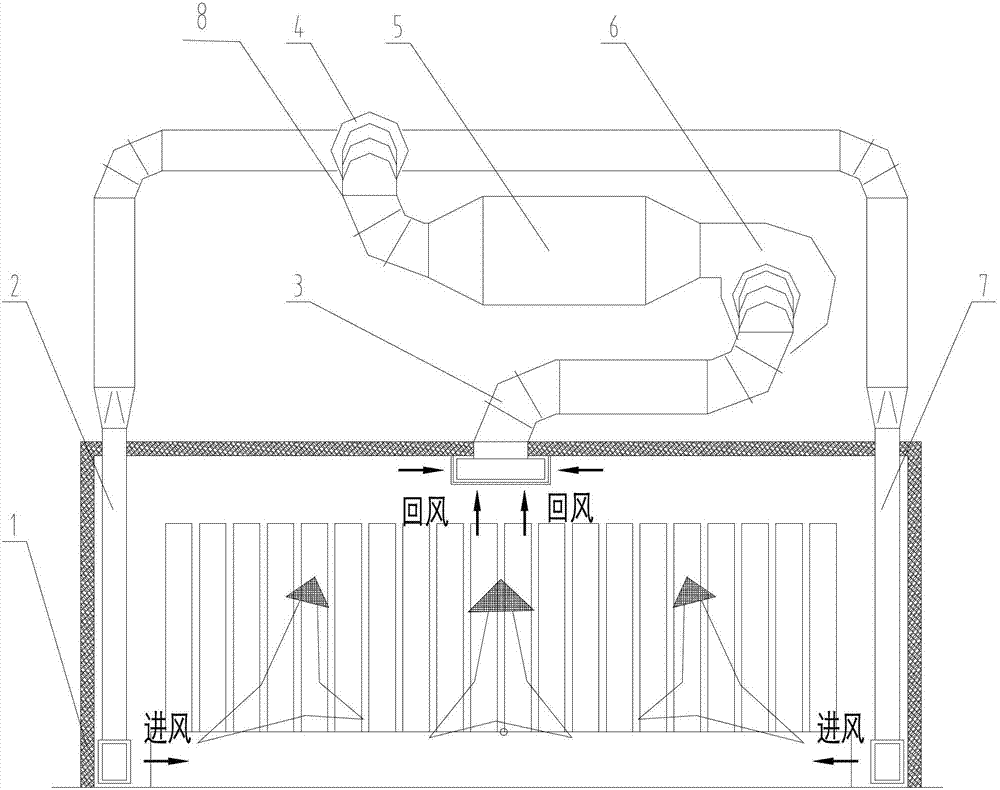

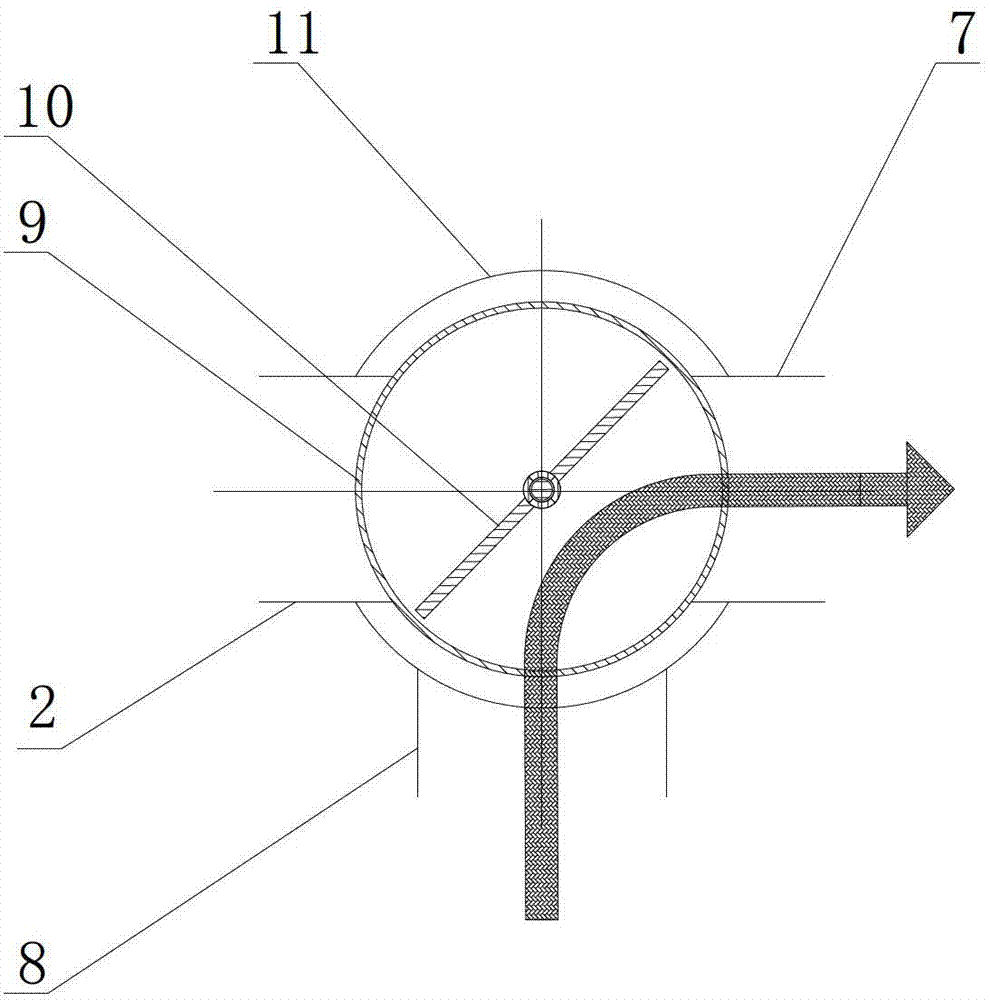

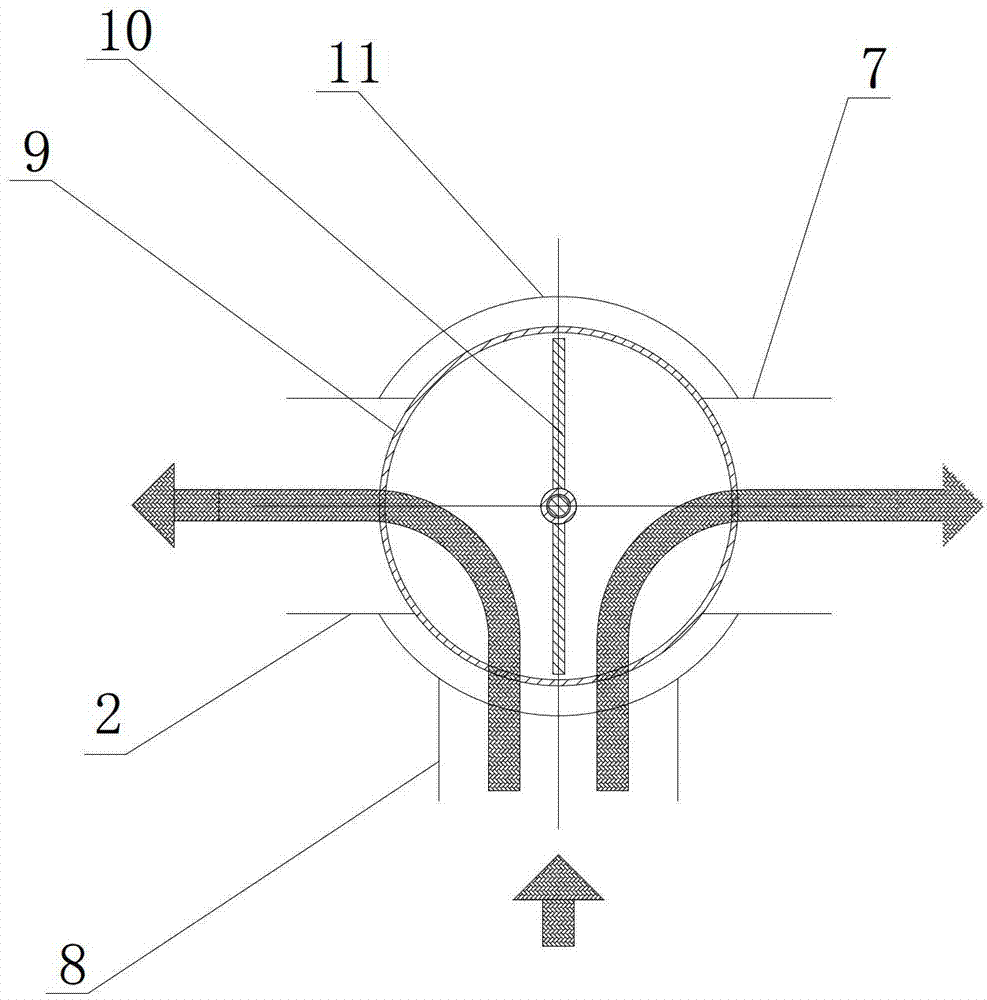

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] In the production of electric porcelain, refractory materials, ceramics, abrasives and other industries, the drying stage is an essential process. The drying process can be divided into the following drying methods according to the type of heat source and the heating method: convection drying, conduction drying, far-infrared drying, microwave drying, freeze drying, vacuum drying, etc. During the drying process, the moisture in the green body to be dried must first migrate from the inside of the green body to the surface of the green body, and then vaporize on the surface and enter the air body. If the process is carried out quickly, the drying time is short and the rate of the drying process is high. However, in industries such as electric porcelain, building materials, refractory materials, daily-use ceramics, and sanitary ware, if the drying speed of the green bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com