Pressure control method for waste heat drying device of waste plastic cracking furnace

A drying device and pressure control technology, applied in the field of automation, can solve problems such as estimation error convergence, achieve the effect of improving accuracy and rapidity, and solving problems of accuracy and rapid convergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing.

[0072] Concrete implementation steps of the present invention are as follows:

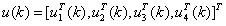

[0073] 1. The establishment of the prediction model of the pressure control system of the drying unit. It is realized through two steps: the first step is to take the valve opening value of the high-temperature flue gas valve, the valve opening value of the cold air valve, the speed of the dryer and the feed amount of waste plastics as the first step. Input the control quantity, use the pressure value of the waste heat drying device collected by the high-precision digital pressure measuring instrument as the output value, and establish the discrete time transfer function model of the pressure control system of the waste heat drying device through the system identification method

[0074]

[0075] in for k The drying gas pressure value collected by the high-precision digital pressure measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com