A production process for improving bipolar transistor bvcbo

A bipolar transistor and production process technology, applied in the field of electronics, can solve the problems of reducing the net doping concentration, limiting the increase and stability of the BVcbo breakdown voltage, and decreasing the radius of curvature of the junction terminal junction, so as to achieve high output power and increase the curvature. Radius, the effect of increasing the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

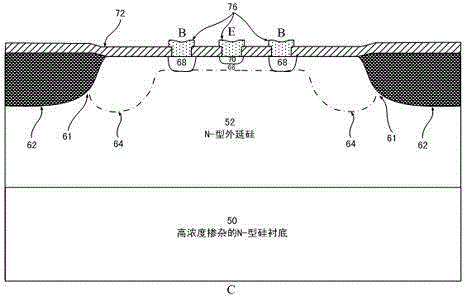

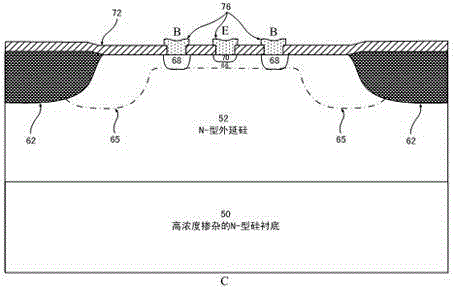

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] The process flow of the above-mentioned NPN silicon bipolar microwave power transistor manufactured by the present invention is described in detail below as shown in the figure.

[0031] A kind of production technology that improves bipolar transistor BVcbo, comprises the steps:

[0032] Step (1): Please refer to image 3, firstly, a highly doped N-type silicon substrate 50 is selected as the extrinsic collector region of the NPN transistor, and the back of the substrate 50 is thinned and gold evaporated after the transistor manufacturing process is completed for forming The collector C of the transistor; the crystal orientation of the substrate 50 can be or , but usually the crystal orientation is selected, and the doped impurity element can be arsenic (As) or It is phosphorus (P) or antimony (Sb), but it is usually arsenic, and the resistivity of the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com