Preparation method of high conductive fluorinated graphene film

A technology of fluorinated graphene and graphene film, which is applied in chemical instruments and methods, carbon fluoride, inorganic chemistry, etc., can solve problems such as unsatisfactory conductivity of graphene film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

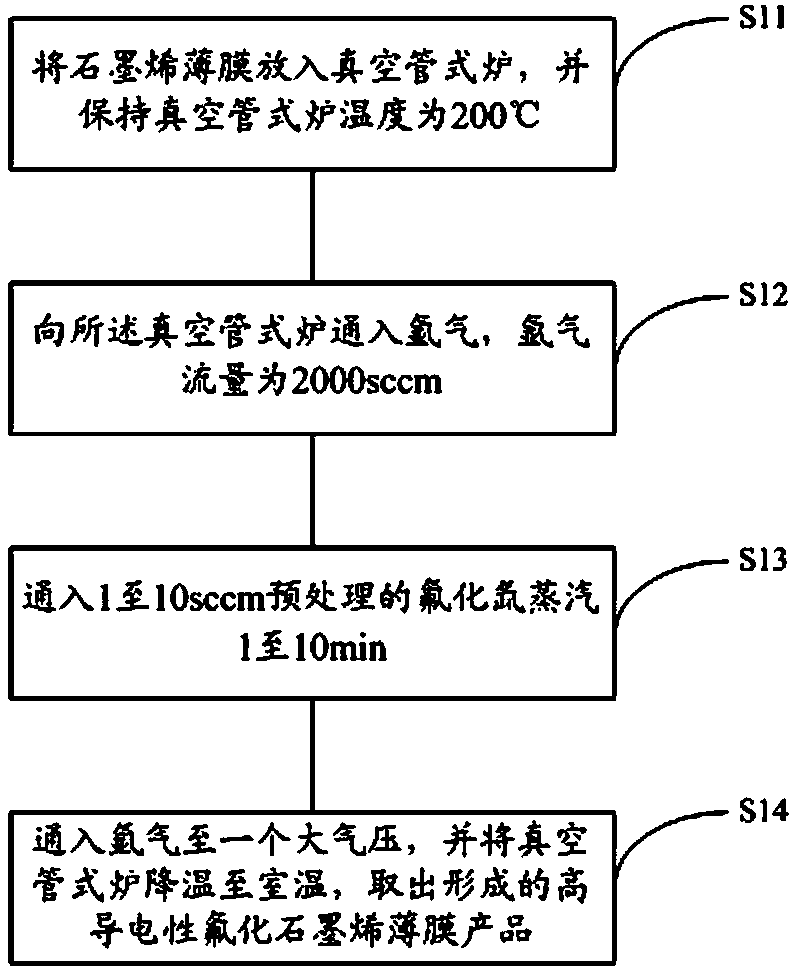

[0018] In view of the above problems, the inventor of the present invention proposes a technical solution, specifically as figure 1 Shown: a preparation method of a highly conductive fluorinated graphene film, comprising the following steps: step S11: put the graphene film into a vacuum tube furnace, and keep the temperature of the vacuum tube furnace at 200 ° C; step S12: add to the The vacuum tube furnace is fed with argon gas, and the flow rate of argon gas is 2000 sccm (Standard Cubic Centimeter per Minute: milliliters per minute); step S13: feed 1 to 10 sccm pretreated xenon fluoride vapor for 1 to 10 min; step S14: feed argon Gas to an atmospheric pressure, and the vacuum tube furnace is cooled to room temperature, and the formed high conductivity fluorinated graphene film product is taken out.

[0019] The preparation method of the highly conductive fluorinated graphene thin film of the present invention is to utilize the characteristics that xenon fluoride has oxidizin...

Embodiment 1

[0022] First, put the 10cm×10cm polished copper sheet into the constant temperature area of the vacuum tube furnace; then, use a vacuum pump to pump the vacuum tube furnace to the background vacuum, about 0.2Pa, and then inject 10sccm hydrogen; put the vacuum tube furnace Heating to 1050°C and keeping at this temperature for 3 minutes; passing 3 sccm methane for 5 minutes, so that the carbon source cracks on the surface of the copper sheet and nucleates and grows to form a graphene film; then, the vacuum tube furnace is naturally cooled to 200 degrees , the argon gas with a flow rate of 2000 sccm is introduced as a protective atmosphere; then the xenon fluoride crystal is preheated for 10 minutes, and the preheating temperature is 100 ° C; after preheating, 10 sccm xenon fluoride vapor is introduced into the vacuum tube furnace for 1 minute; finally , stop heating, turn off the vacuum pump, and pass argon gas to an atmospheric pressure, and after cooling down to room temperat...

Embodiment 2

[0024] First, put the 10cm×10cm polished copper sheet into the constant temperature area of the vacuum tube furnace; use a vacuum pump to pump the vacuum tube furnace to the background vacuum, about 0.5 Pa, and then inject 10 sccm hydrogen; heat the vacuum tube furnace to 800 ℃, kept at this temperature for 20 minutes; 3sccm methane was passed into the vacuum tube furnace for 20 minutes, so that the carbon source was cracked on the surface of the copper sheet and nucleated and grown to form a graphene film; the vacuum tube furnace was naturally cooled to 200 °C; Enter argon as a protective atmosphere, and the flow rate is 2000 sccm; preheat the xenon fluoride crystal for 10 minutes, and the preheating temperature is 180 degrees; then, feed 1 sccm preheated xenon fluoride vapor into the vacuum tube furnace for 10 minutes; keep the vacuum tube The temperature of the furnace is 200°C; finally, stop the heating, turn off the vacuum pump, feed argon to an atmospheric pressure, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com