Tm and Eu mono/co-doped lutecium gallium garnet phosphor

A gallium garnet and phosphor technology, applied in the field of luminescent materials, can solve the problems of precursor powder agglomeration, difficulty in forming precursor powder and difficult control of sedimentation rate, and achieve narrow emission peak, easy ball milling, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

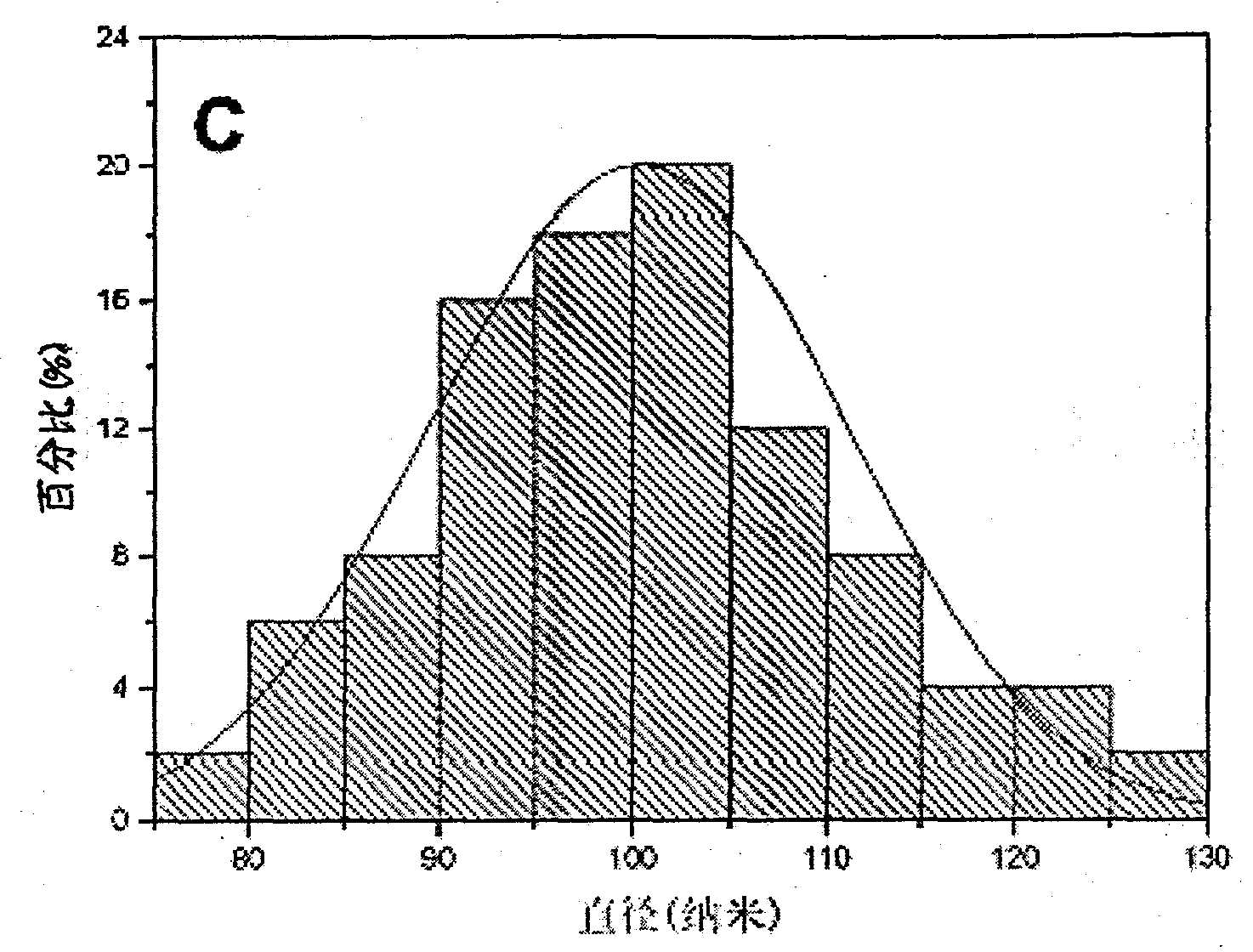

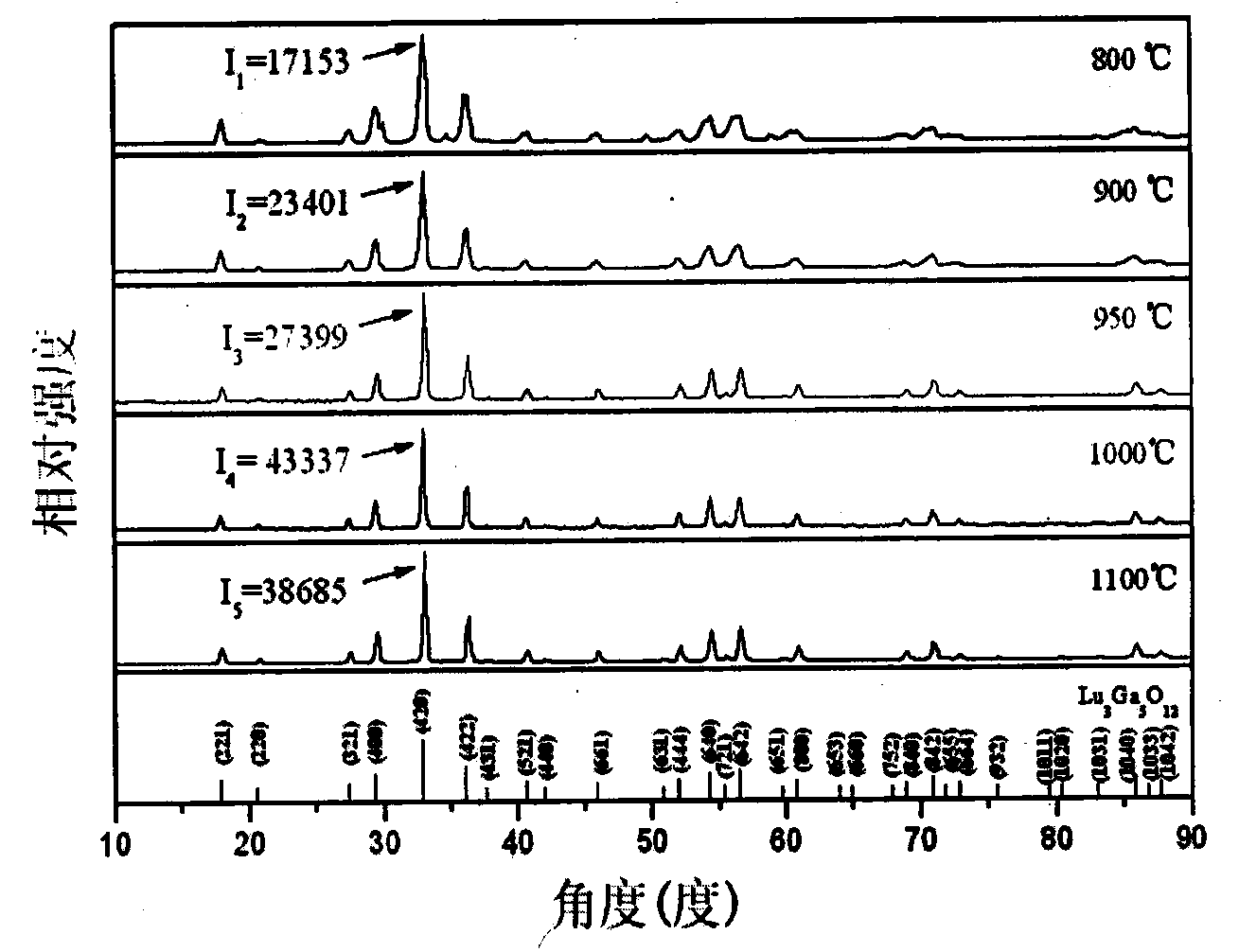

[0024] Embodiment 1 A kind of europium monodoped lutetium gallium garnet (LGG) fluorescent powder, chemical formula is Lu 2.98 Ga 5 o 12 :0.02Eu 3+ ;

[0025] 1) dissolving gallium oxide powder with concentrated nitric acid with a mass fraction of 69%; dissolving europium nitrate and lutetium nitrate in deionized water, mixing the two solutions to form a metal ion solution; wherein, Lu 3+ :Eu 3+ : Ga 3+ The molar ratio is 2.98:0.02:5;

[0026] 2) Add citric acid to the metal ion mixed solution prepared in step 1, and mix well to obtain a mixed solution, wherein the molar ratio of citric acid to the sum of the contents of all metal ions is 1.5:1;

[0027] 3) Put the mixed solution in step 2 in a water bath at 80°C for 0.5h, until all of it turns into a pale yellow gel;

[0028] 4) Move the light yellow gel in step 3 into an oven, and keep the temperature at 250° C. for 2 hours to obtain dark brown bulky powder;

[0029] 5) The dark brown bulky powder obtained in step 4) i...

Embodiment 2

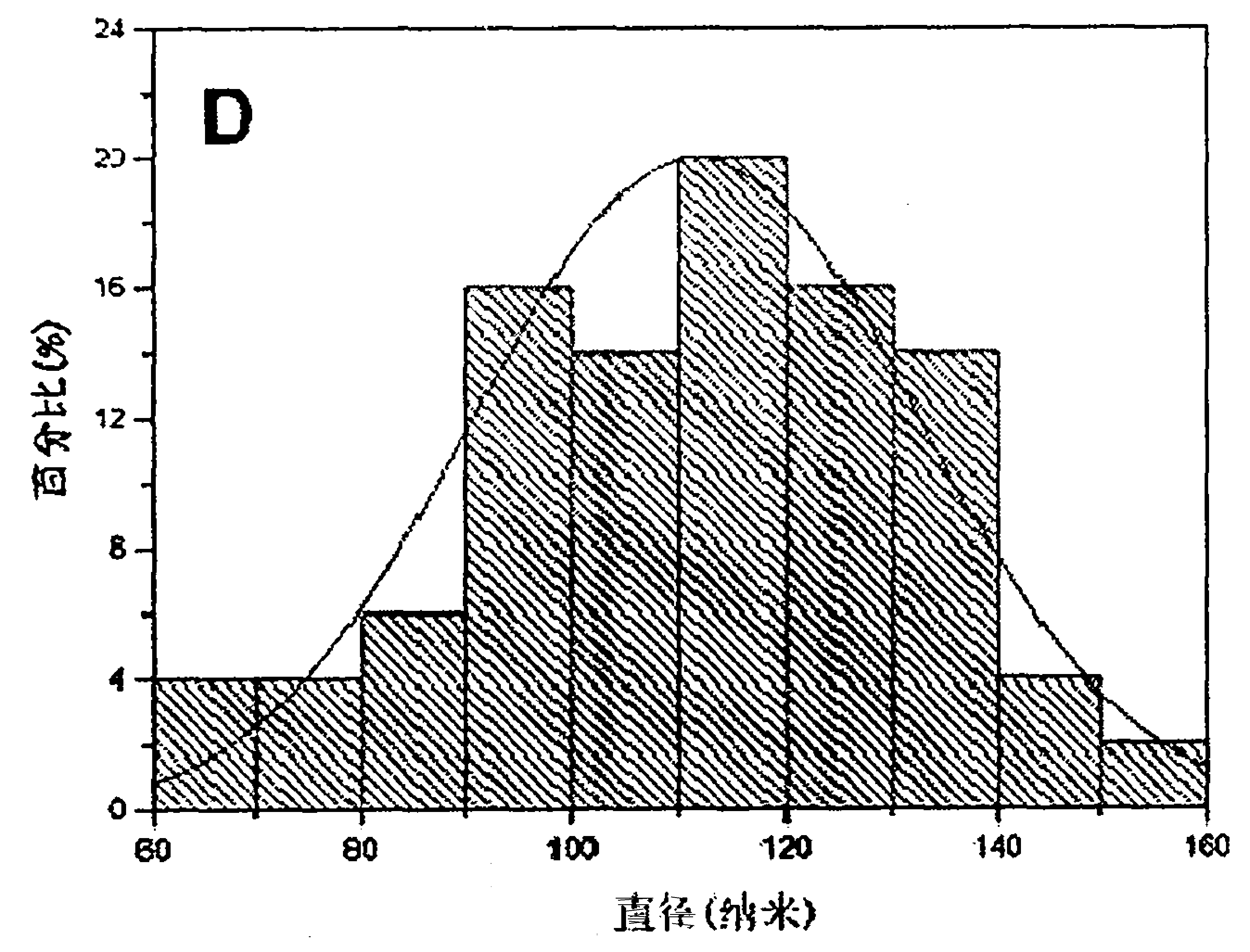

[0031] Embodiment 2 A kind of europium monodoped lutetium gallium garnet (LGG) fluorescent powder, its chemical formula is Lu 2.96 Ga 5 o 12 :0.04Eu 3+ .

[0032] 1) gallium oxide powder is dissolved in concentrated nitric acid with a mass fraction of 69%; europium nitrate and lutetium nitrate are dissolved in deionized water, and the two solutions are mixed to form a metal ion solution; wherein, Lu 3+ :Eu 3+ : Ga 3+ The molar ratio is 2.96:0.04:5;

[0033] 2) Add citric acid to the metal ion mixed solution prepared in step 1, and mix well to obtain a mixed solution, wherein the molar ratio of citric acid to the sum of the contents of all metal ions is 1.5:1;

[0034] 3) Put the mixed solution in step 2 in a water bath at 80°C for 1 hour until all of it turns into a pale yellow gel;

[0035] 4) Move the light yellow gel in step 3 into an oven, and keep the temperature at 250° C. for 4 hours to obtain dark brown bulky powder;

[0036] 5) The dark brown bulky powder obta...

Embodiment 3

[0037] Embodiment 3 A kind of europium monodoped lutetium gallium garnet (LGG) fluorescent powder, its chemical formula is Lu 2.99 Ga 5 o 12 :0.01Eu 3+ .

[0038] 1) dissolving gallium oxide powder with concentrated nitric acid with a mass fraction of 69%; dissolving europium nitrate and lutetium nitrate in deionized water, mixing the two solutions to form a metal ion solution; wherein, Lu 3+ :Eu 3+ : Ga 3+ The molar ratio is 2.99:0.01:5;

[0039] 2) Add citric acid to the metal ion mixed solution prepared in step 1, and mix well to obtain a mixed solution, wherein the molar ratio of citric acid to the sum of the contents of all metal ions is 1.5:1;

[0040] 3) Put the mixed solution in step 2 in a water bath at 80°C for 0.8h, until all of it turns into a pale yellow gel;

[0041] 4) Move the light yellow gel in step 3 into an oven, and keep the temperature at 250° C. for 2 hours to obtain dark brown bulky powder;

[0042] 5) The black-brown bulky powder obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com