Method for preparing YBCO (yttrium barium copper oxide) film by taking ethanol as solvent through low-fluorine MOD (metal organic deposition) method

A technology of ethanol solution and ethanol water solution, which is applied in the field of materials, can solve problems such as the environmental hazards of trifluoroacetic acid gas, and achieve the effects of good application prospects, good superconductivity, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

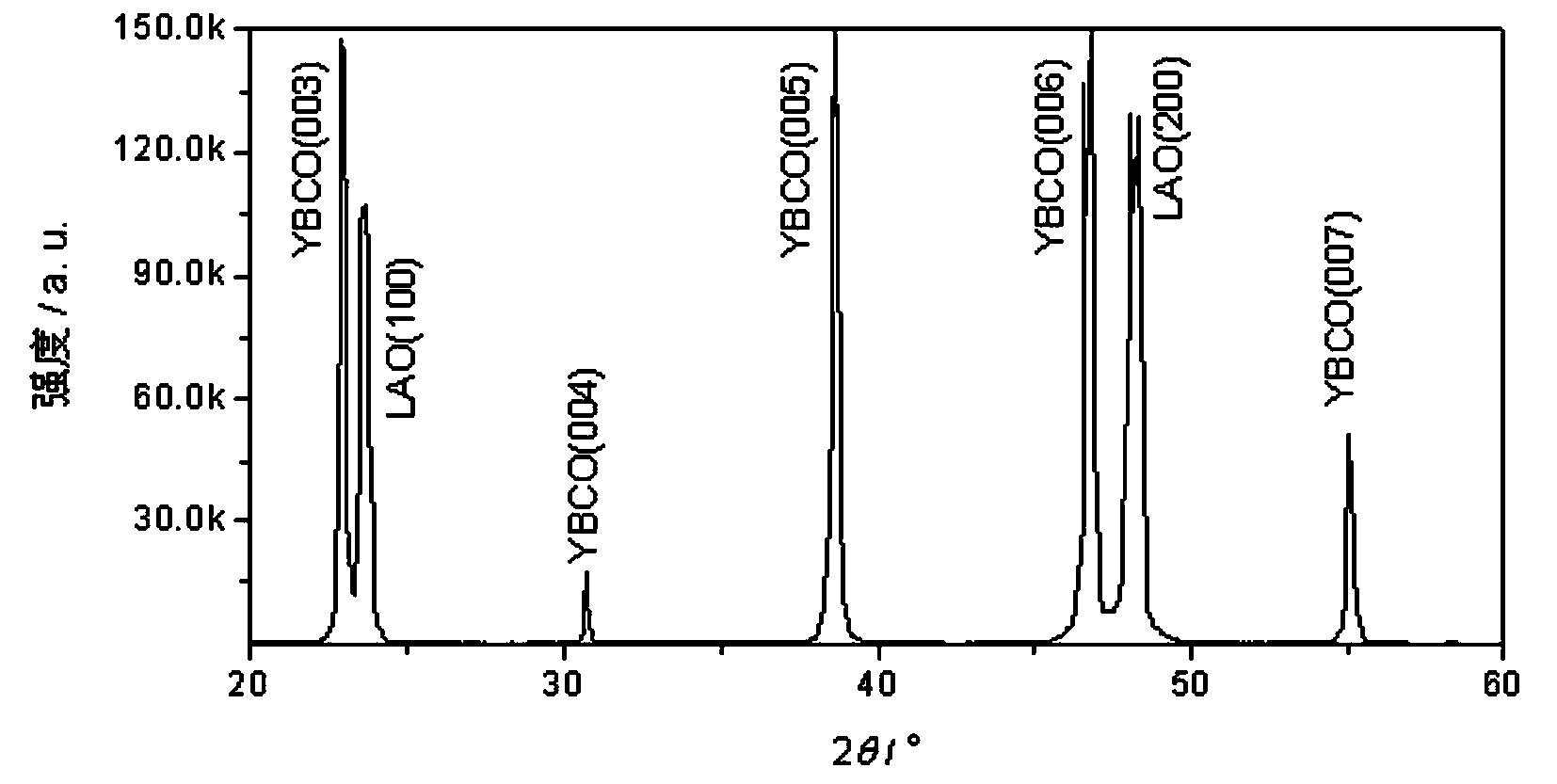

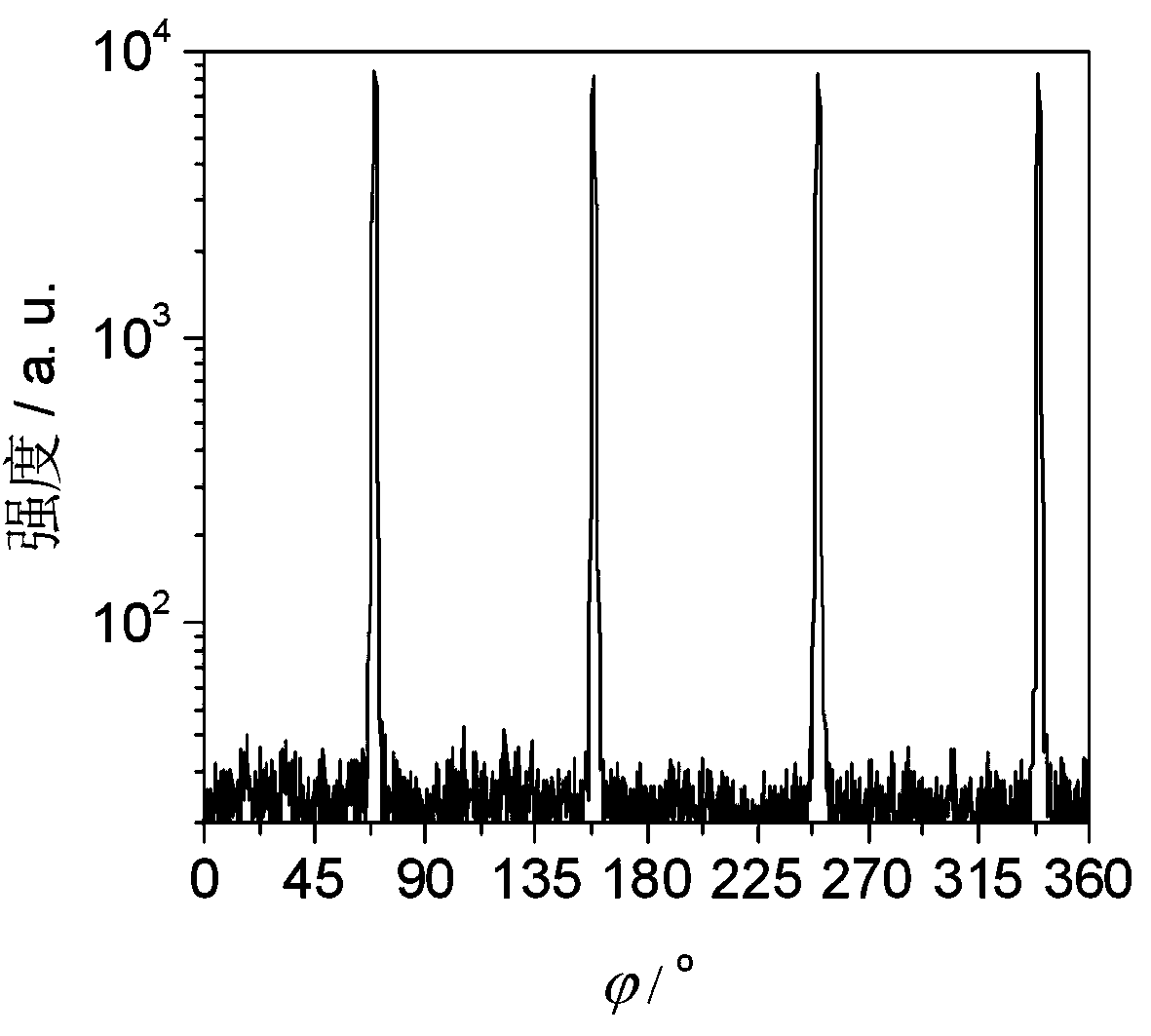

Image

Examples

Embodiment 1

[0049] Dissolve yttrium acetate and barium trifluoroacetate in deionized water. In order to accelerate the dissolution, heat the deionized water to 70~80°C to make yttrium-barium solution. The molar ratio of yttrium ion and barium ion in the yttrium-barium solution is 1: 2. Control the total concentration of yttrium ions and barium ions in the yttrium-barium solution to be 0.25mol / L;

[0050] The yttrium-barium solution is boiled until the total concentration of yttrium ion and barium ion in the yttrium-barium solution is 0.6mol / L;

[0051] Add dehydrated alcohol to the yttrium-barium solution that the total concentration of yttrium ion and barium ion is 0.6mol / L, form the yttrium-barium ethanol solution, control the total concentration of yttrium ion and barium ion in the yttrium-barium ethanol solution to be 0.3mol / L, Then boil until the total concentration of yttrium ion and barium ion is 0.6mol / L; repeat the operation of adding dehydrated alcohol and boiling again 4 times ...

Embodiment 2

[0063] Dissolve yttrium acetate and barium trifluoroacetate in deionized water. In order to accelerate the dissolution, heat the deionized water to 70~80°C to make yttrium-barium solution. The molar ratio of yttrium ion and barium ion in the yttrium-barium solution is 1: 2. Control the total concentration of yttrium ions and barium ions in the yttrium-barium solution to be 0.3mol / L;

[0064] The yttrium-barium solution is boiled until the total concentration of yttrium ion and barium ion in the yttrium-barium solution is 0.5mol / L;

[0065] Add dehydrated alcohol to the yttrium-barium solution that the total concentration of yttrium ion and barium ion is 0.5mol / L, form the yttrium-barium ethanol solution, control the total concentration of yttrium ion and barium ion in the yttrium-barium ethanol solution to be 0.25mol / L, Then boil until the total concentration of yttrium ion and barium ion is 0.5mol / L; repeat the operation of adding dehydrated alcohol and boiling again 5 times ...

Embodiment 3

[0073] Dissolve yttrium acetate and barium trifluoroacetate in deionized water. In order to accelerate the dissolution, heat the deionized water to 70~80°C to make yttrium-barium solution. The molar ratio of yttrium ion and barium ion in the yttrium-barium solution is 1: 2. Control the total concentration of yttrium ions and barium ions in the yttrium-barium solution to be 0.4 mol / L;

[0074] The yttrium-barium solution is boiled until the total concentration of yttrium ion and barium ion in the yttrium-barium solution is 0.8 mol / L;

[0075] Add dehydrated alcohol to the yttrium-barium solution that the total concentration of yttrium ion and barium ion is 0.8 mol / L, form yttrium-barium ethanol solution, control the total concentration of yttrium ion and barium ion in the yttrium-barium ethanol solution to be 0.4 mol / L, Then boil until the total concentration of yttrium ions and barium ions is 0.8 mol / L; repeat the operation of adding absolute ethanol and boiling again 6 times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com