Method for preparing octahedral platinoid alloy nanocrystals and octahedral platinoid alloy nanocrystal prepared through adopting same

A platinum-copper alloy and nanocrystal technology, applied in the field of nanomaterials, can solve the problems of complex reaction process and experimental conditions, difficult large-scale production, etc., and achieve the effects of good size uniformity, high repeatability, and easy preparation and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

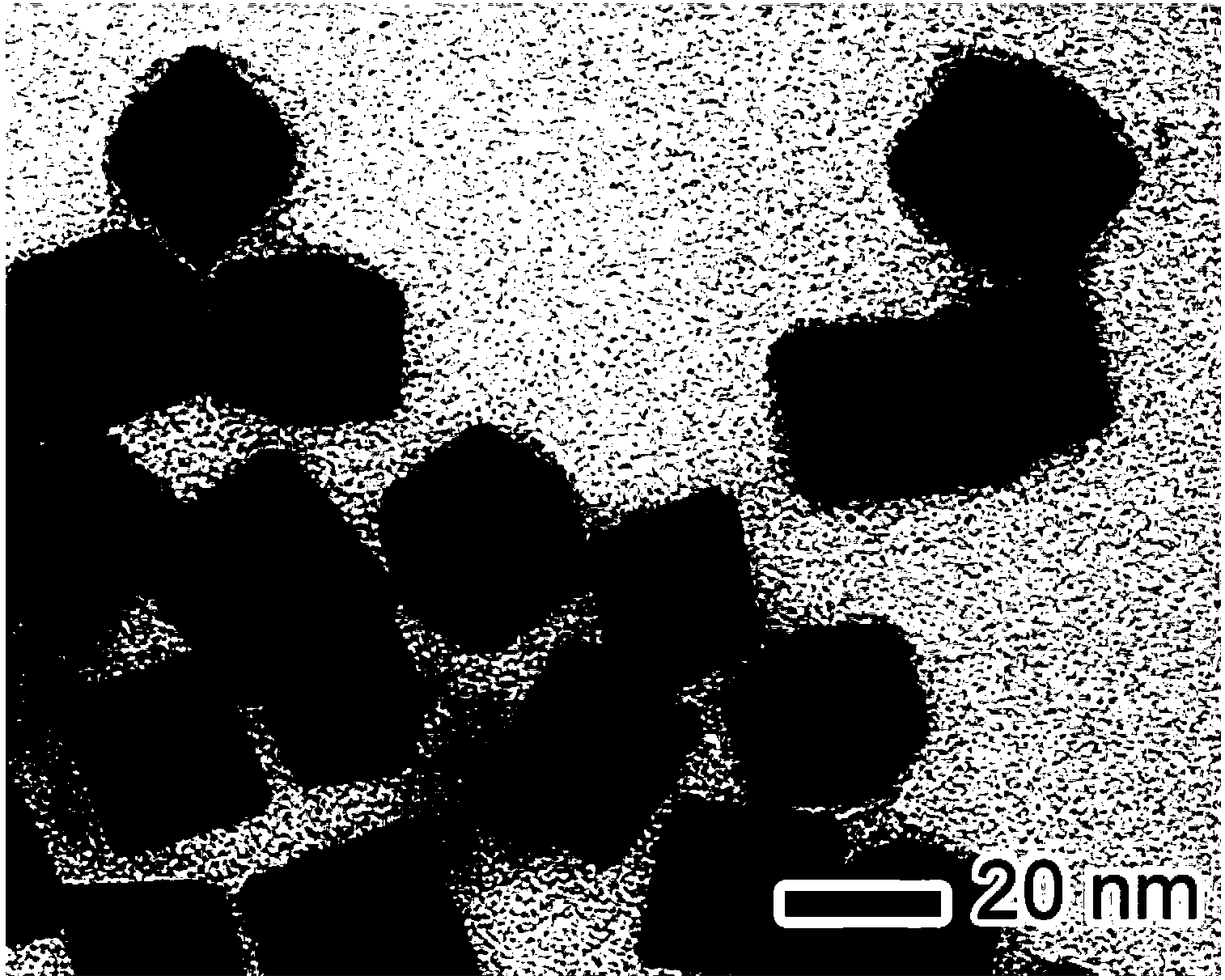

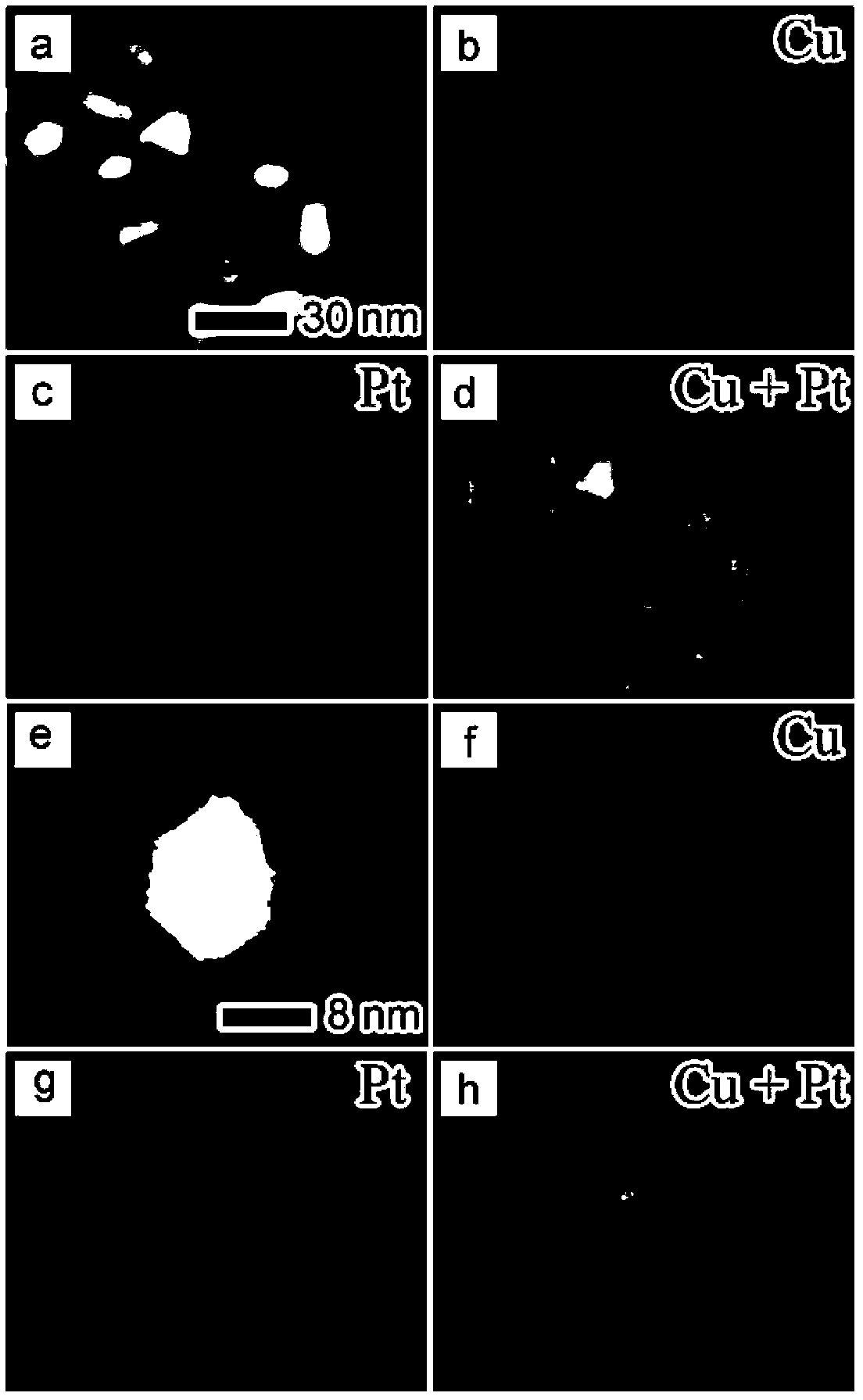

Image

Examples

Embodiment 1

[0027] (1) Equipped with chloroplatinic acid (H 2 PtCl 6 ) and copper chloride (CuCl 2 ) in DMF solution, the concentrations are 0.038mol / L and 0.05mol / L respectively;

[0028] (2) Add 0.18mol / L polyvinylpyrrolidone (PVP) with a molecular weight of 30,000 to 20mL DMF solvent, and dissolve it by ultrasonication for 2-3 minutes;

[0029] (3) Add the prepared chloroplatinic acid and copper chloride solution into (2) the mixed solution, wherein the volume ratio of the copper source solution to the platinum source solution: 6:1, the mixed solution and the DMF solution in step (2) The volume ratio is 1:20, sonicate for 1 to 2 minutes to mix evenly;

[0030] (4) Add the mixed solution obtained in (3) into a hydrothermal kettle with a volume of 40mL, and react at 200°C for 11h;

[0031] (5) Centrifuge the product obtained in (4) at a speed of 12000-13000 rpm for 10 minutes, discard the supernatant, and remove excess PVP;

[0032] (6) Ultrasonic disperse the precipitate obtained i...

Embodiment 2

[0035] (1) Equipped with chloroplatinic acid (H 2 PtCl 6 ) and copper chloride (CuCl 2 ) in DMF solution, the concentrations are 0.045mol / L and 0.03mol / L respectively;

[0036] (2) Add 0.18 mol / l polyethylene glycol (PEG-2000) with a molecular weight of 55,000 into 20 mL of DMF solvent, and dissolve it by ultrasonication for 2-3 minutes;

[0037] (3) Add the prepared potassium platinate and cupric chloride solution into (2) the mixed solution, wherein the volume ratio of the copper source solution to the platinum source solution: 4:1, the ratio of the mixed solution to the DMF solution in step (2) The volume ratio is 1:20, sonicate for 1 to 2 minutes to mix evenly;

[0038] (4) Add the mixed solution obtained in (3) into a hydrothermal kettle with a volume of 40mL, and react at 190°C for 11h;

[0039] (5) Centrifuge the product obtained in (4) at a speed of 12000-13000 rpm for 10 minutes, discard the supernatant, and remove excess PVP;

[0040] (6) Ultrasonic disperse the...

Embodiment 3

[0042] (1) Equipped with potassium chloroplatinate (K 2 PtCl 6 ) and copper chloride (CuCl 2 ) in DMF solution, the concentrations are 0.05mol / L and 0.05mol / L respectively;

[0043](2) Add 0.18mol / l polyethylene glycol with a molecular weight of 2000 to 20ml of DMF solvent, and dissolve it by ultrasonication for 2-3 minutes;

[0044] (3) Add the prepared potassium chloroplatinate and copper chloride solution into (2) the mixed solution, wherein the volume ratio of the copper source solution to the platinum source solution: 3:1, the volume of the mixed solution and the DMF solution in step 2 The ratio is 1:25, ultrasonic 1 ~ 2min to mix evenly;

[0045] (4) Add the mixed solution obtained in (3) into a hydrothermal kettle with a volume of 40mL, and react at 180°C for 11h;

[0046] (5) Centrifuge the product obtained in (4) at a speed of 12000-13000 rpm for 10 minutes, discard the supernatant, and remove excess PEG;

[0047] (6) Ultrasonic disperse the precipitate obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com