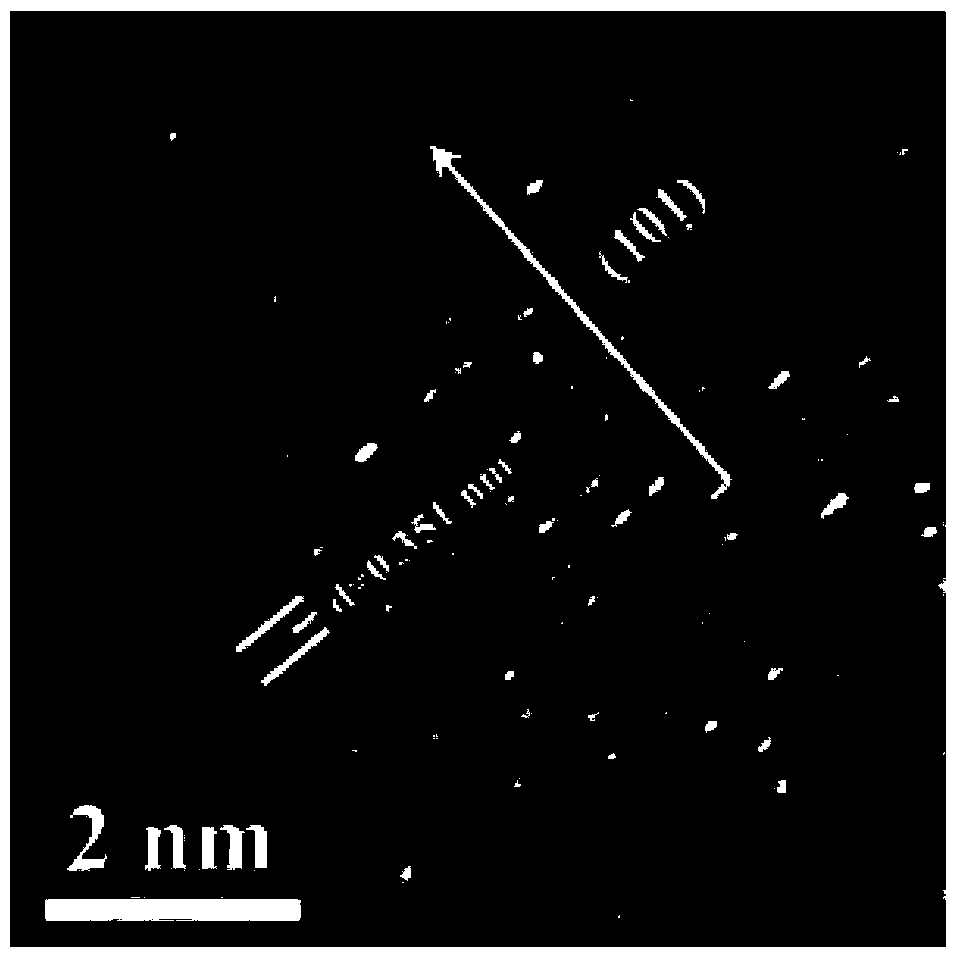

Preparation method for titanium dioxide nanocrystal/carbon composite photocatalyst

A nanocrystal, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor stability, nanocrystal composite, complex preparation methods, etc., and achieve high crystal stability. , the effect of increased photocatalytic performance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment 1: The method for preparing titanium dioxide nanocrystal / carbon composite photocatalyst of this embodiment is specifically carried out according to the following steps:

[0023] 1. Mix titanate and acrylic monomer, magnetically stir for 5h-30h to obtain a mixture, wherein the ratio of the amount of titanate and acrylic monomer is 1:1-10;

[0024] 2. Control the temperature to 70°C, mix the azobisisobutyronitrile and the mixture obtained in step one uniformly, and keep it for 10 to 50 minutes to obtain a prepolymer;

[0025] 3. The prepolymer obtained in step 2 is reacted at a temperature of 70°C for 10h-30h, then at a temperature of 80°C for 0.5h-10h, and then at a temperature of 90°C for 0.5h-10h, Then react at a temperature of 100°C for 0.5h-10h, and then react at a temperature of 120°C for 0.5h-20h to obtain a polymer;

[0026] 4. The polymer obtained in step 3 is heated to a temperature of 900° C., and maintained under a nitrogen atmosphere for 0.5 h to ...

specific Embodiment approach 2

[0027] Specific embodiment two: this embodiment is different from specific embodiment one in that the titanate described in step one is isopropyl titanate, butyl titanate or tetrabutyl titanate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: This embodiment is different from specific embodiment one in that the acrylic monomer in step one is methacrylic acid, ethacrylic acid or dimethacrylic acid. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com