Carrier of silver catalyst for olefin epoxidation as well as preparation method and application thereof

A technology of silver catalyst and alumina carrier, which is applied in the direction of catalyst carrier, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of reducing the rate of decline in catalyst selectivity and achieve selectivity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

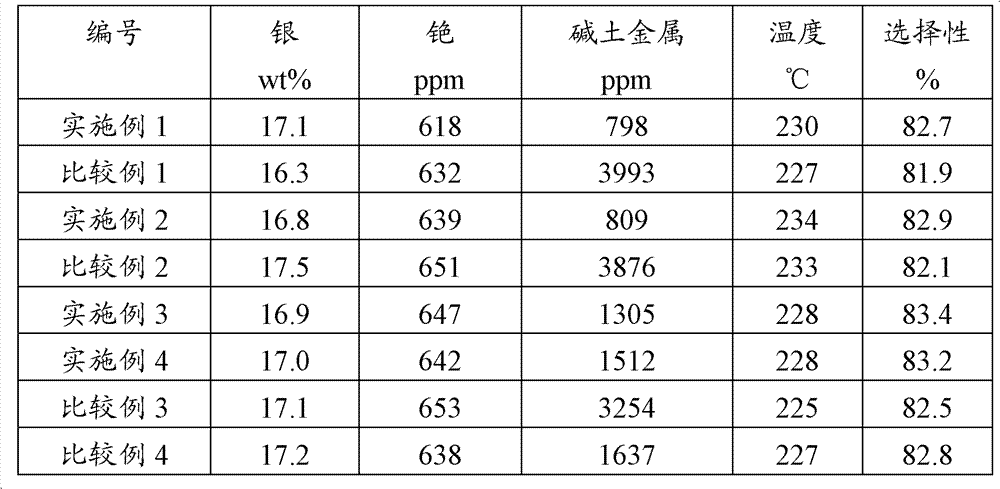

Embodiment 1

[0056] a) Preparation of carrier

[0057] 50-500 mesh, α-trihydrate Al 2 o 3 312g, more than 200 mesh, heavy alkaline earth metal content of 227ppm (by mass) fake Al monohydrate 2 o 3 92g, NH 4 F 7g was put into a mixer and mixed evenly, transferred to a kneader, added 0.12 liters of dilute nitric acid (nitric acid: water=1:3, weight ratio), and kneaded into a paste that could be extruded. Extrude into a five-hole column with an outer diameter of 8.0mm, a length of 6.0mm, and an inner diameter of 1.0mm, and dry it at 80-120°C for more than 2 hours to reduce the free water content to below 10%.

[0058] Put the above-mentioned five-hole column into a bell kiln, raise it from room temperature to 1400°C in about 30 hours, and keep the temperature constant for 4 hours to obtain white α-Al 2 o 3 Carrier samples. The measured carrier performance data are listed in Table 1.

[0059] b) Preparation of silver catalyst

[0060] Take 700g of silver nitrate and dissolve it in 7...

Embodiment 2

[0072] Same as Example 1, except that 61 g of petroleum coke was added when preparing the carrier. Carrier data are shown in Table 1. Silver catalyst data and catalytic performance data are shown in Table 2.

Embodiment 3

[0078] With embodiment 1, difference is that, use heavy alkaline earth metal content to be the α-trihydrate Al of 490ppm 2 o 3 212g, heavy alkaline earth metal content is the false monohydrate Al of 52ppm 2 o3 192g and add Vaseline 10g, NH 4 F7g; the temperature of the five-hole column is raised from room temperature to 1230°C for 12 hours; when preparing the impregnation solution, add 2.8g of strontium acetate instead of 3.6g of barium acetate, 0.3g of lithium sulfate and 0.6g of perrhenic acid; after impregnation The carrier was heated at 220°C. The data of the prepared carrier is shown in Table 1; the data of the silver catalyst and the catalytic performance data are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com