Spontaneous combustion device and method for preparing superfine La2CuO4 powder at low temperature by ultrasonic-combustion method with assistance of spontaneous combustion device

An ultra-fine powder, combustion method technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of inability to prepare ultra-fine powder in large quantities, long self-ignition time, incomplete combustion, etc. Avoid product loss, accelerate dissolution, and promote complete complexation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

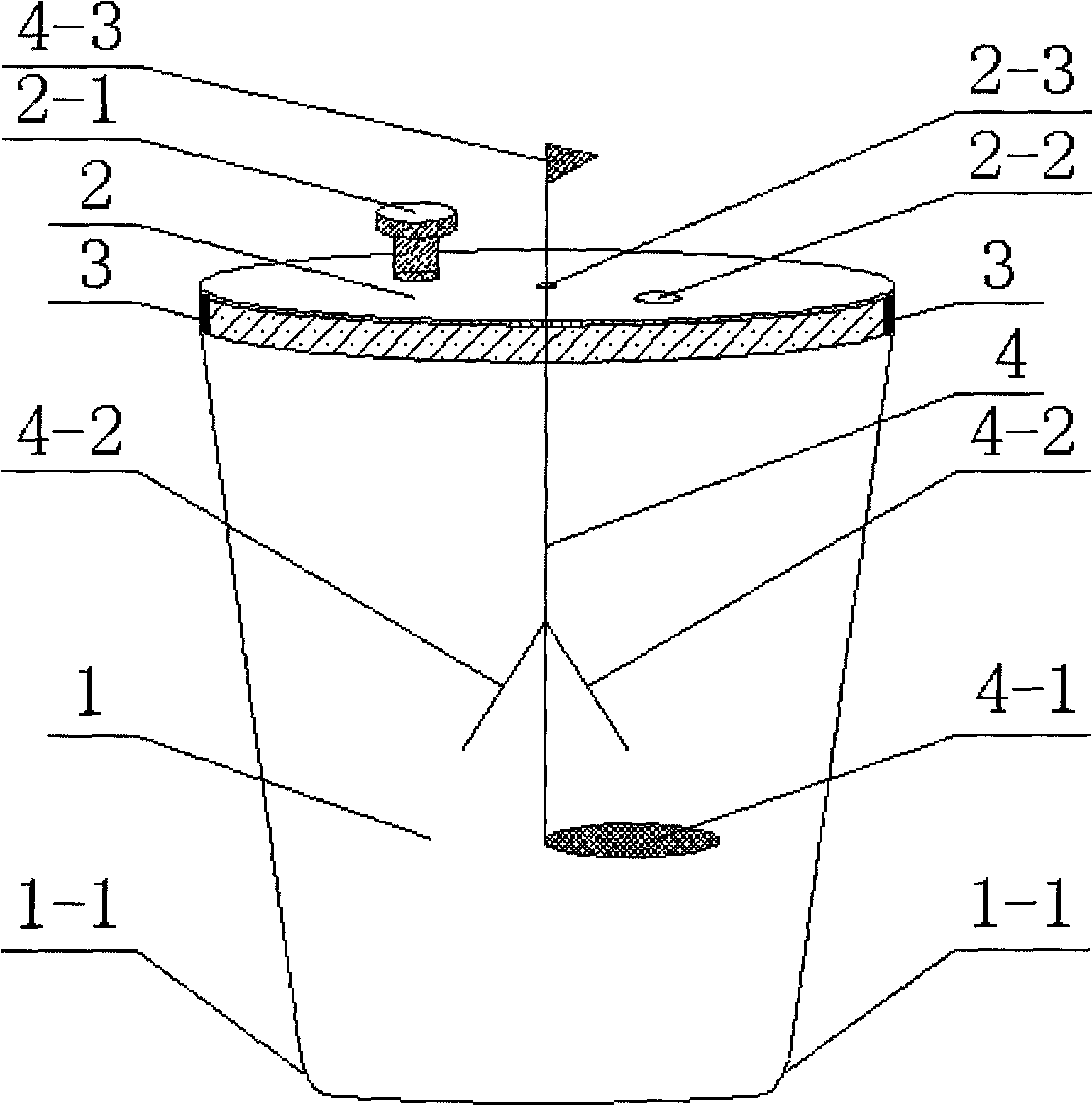

[0015] Specific implementation mode one: combine figure 1 , this embodiment is a self-ignition device, characterized in that the self-ignition device includes a glass body 1, a cup cover 2, a rubber ring 3 and a joystick 4, a handle 2-1 is set on the cup cover 2, and a handle 2-1 is placed on the cup cover 2. Feeding hole 2-2 and small hole 2-3 are set, oval baffle 4-1 is installed at the bottom of joystick 4, stirring handrail 4-3 is installed at the top of joystick 4, and oval shape is arranged on joystick 4 A compressible bracket 4-2 is installed between the baffle 4-1 and the stirring armrest 4-3; the glass body 1 is an inverted conical glass with an open upper end, and the lid 2 is sealed on the glass body 1 by a rubber ring 3 On, the joystick 4 passes through the small hole 2-3 on the cup cover 2, and the stirring armrest 4-3 on the joystick 4 is placed outside the glass body 1, and the oval baffle 4-1 on the joystick 4 and The compressible support 4-2 is installed in t...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 The difference between this embodiment and the first embodiment is that: the cup body and the base of the glass cup body 1 are connected by an arc-shaped corner 1-1. Others are the same as the first embodiment.

[0019] In this embodiment, the corners of the glass cup body are arranged in an arc shape, which is beneficial to the collection of the generated powder.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 The difference between this embodiment and the specific embodiment one or two is: the diameter of the small hole 2-3 is set as M, and the diameter of the joystick 4 is set as N, then: 0.2cm<M-N< 0.4cm. Others are the same as those in Embodiment 1 or 2.

[0021] In the present embodiment, the aperture of the small hole 2-3 is larger than the diameter of the joystick 4, which is convenient for the joystick 4 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com