Preparation method for isoprene and limonene

A technology of isoprene and isoprenoid, applied in the field of preparation of isoprene and limonene, can solve the problem of low production yield of limonene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

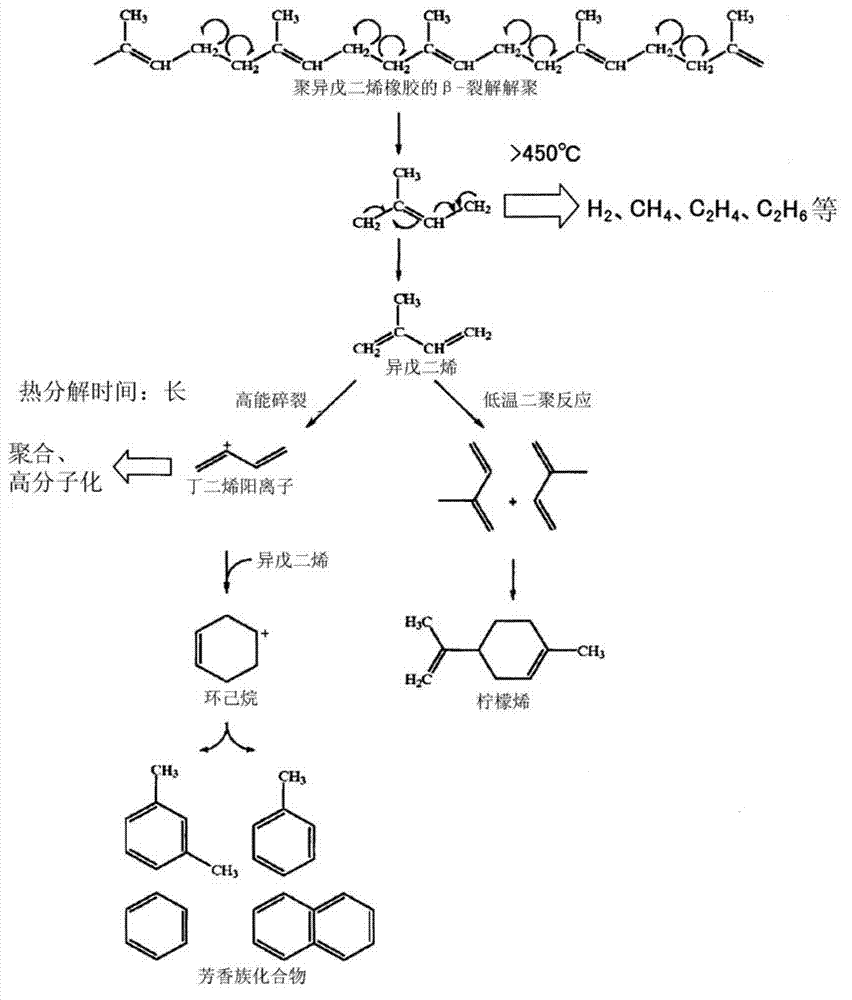

[0033] The preparation method of isoprene and limonene of the present invention includes the step of thermally decomposing a biopolymer mainly composed of isoprenoid. In the method of the present invention, one of isoprene and limonene, or both of isoprene and limonene are produced by the thermal decomposition step.

[0034] In this specification, the so-called isoprene refers to the structural formula CH 2 =C(CH 3 )CH=CH 2 hydrocarbons with two double bonds. There are three types of limonene, d-body, l-body and d / l-body, each of which is composed of two isoprene units. The d-body and the l-body are represented by the following general formula (I).

[0035] [chemical formula 1]

[0036]

[0037] A biopolymer with isoprenoid as the main component is a biopolymer biosynthesized using pentenyl pyrophosphate as an intermediate. The pentenyl pyrophosphate is composed of isopentenyl Diene units are connected continuously, and the pentenyl pyrophosphate is biosynthesized by ...

Embodiment

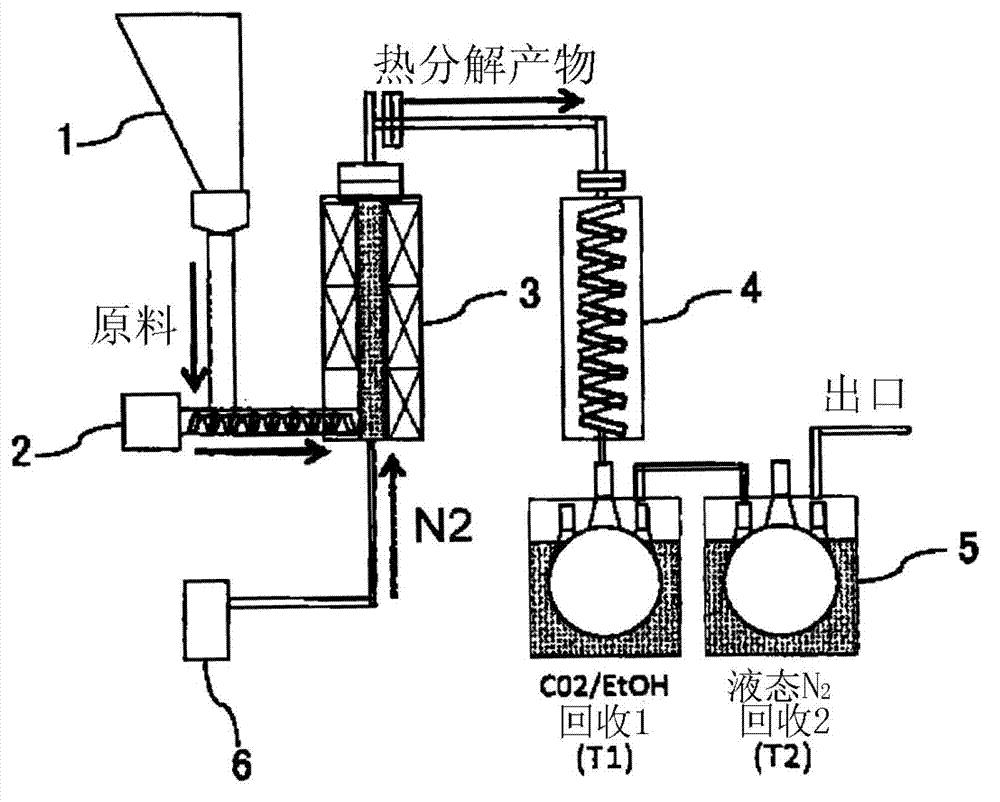

[0056] Below, refer to figure 2 , the present invention will be described in detail through examples, but the present invention is not limited to these examples.

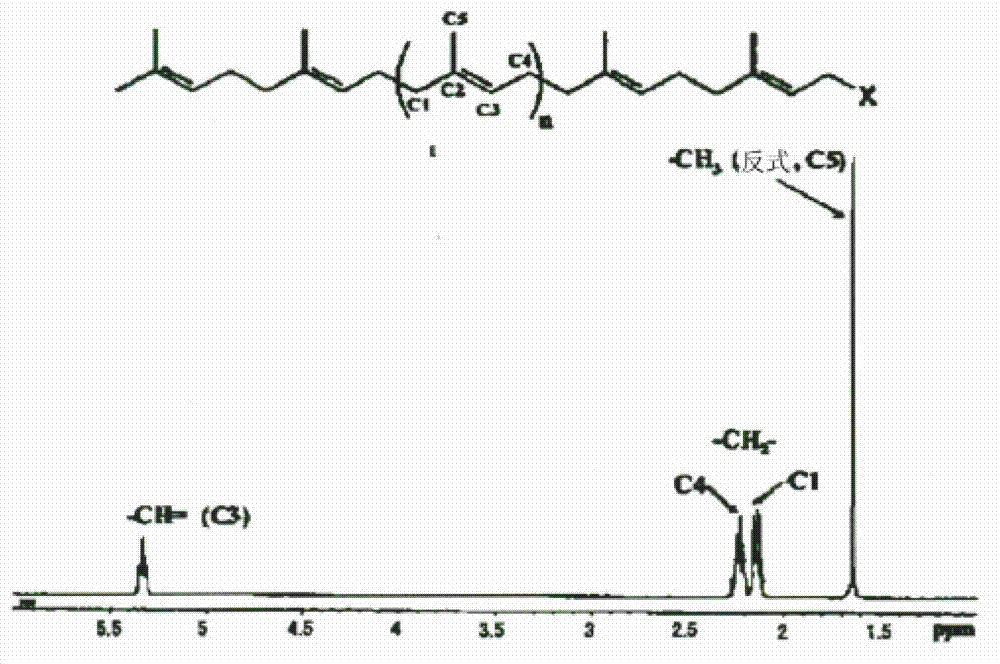

[0057] As a raw material biopolymer, Eucommia rubber purified product 1 obtained by the method described in JP-A-2009-221306 was used. It is mainly composed of trans-type terpenoids, with a weight average molecular weight of 10 3 ~10 6 . The NMR (nuclear magnetic resonance) spectrum and structural formula of the raw materials are as follows image 3 shown.

[0058] Use a pulverizer to pulverize the raw materials, sieve through a sieve with a pore size of 2 mm, and select pulverized materials smaller than 2 mm. Fill 5 kg of crushed and sieved raw materials into the raw material storage tank 1 (filled with nitrogen in advance). Simultaneously with the start of the feedstock filling, the nitrogen filling was terminated.

[0059] Using the raw material supply device 2, the raw material filled in the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com