Composite flame-retardant and antimicrobial PVC-U (unplasticised polyvinyl chloride) pipe and preparation method thereof

A PVC-U, composite flame retardant technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of no functional composite discussion, single performance of disinfectants and flame retardants, etc., to achieve good thermal welding performance, not easy Degradation, good chemical resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A composite flame-retardant and antibacterial PVC-U drainage pipe, the mass percentage of its raw materials is:

[0073] Functional masterbatch 0.1%

[0074] PVC-U masterbatch 99.9%

[0075] A preparation method of a composite flame-retardant and antibacterial PVC-U drainage pipe, the specific steps of which are:

[0076] Raw material+color masterbatch→mixing→vacuum feeding→raw material drying→single-screw extruder→color line extruder→spiral mold→sizing sleeve→spray vacuum calibrating box→spray cooling water tank→jet printer→ Crawler tractor → finished product inspection and packaging PVC-U pipe specifications; color masterbatch can be changed according to actual needs.

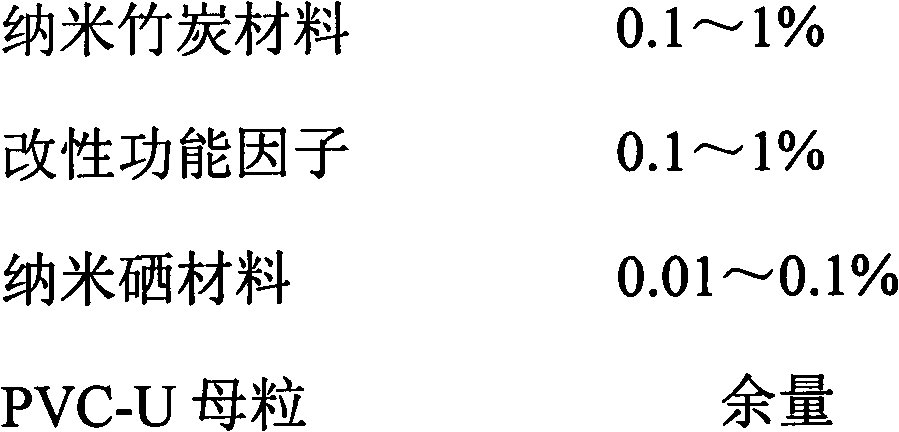

[0077] A kind of functional masterbatch, its raw material mass percentage is:

[0078]

[0079] The particle size of the nano-bamboo charcoal material is 20nm.

Embodiment 2

[0081] A composite flame-retardant and antibacterial PVC-U drainage pipe, the mass percentage of its raw materials is:

[0082] Functional masterbatch 0.3%

[0083] PVC-U masterbatch 99.7%

[0084] A preparation method of a composite flame-retardant and antibacterial PVC-U drainage pipe, the specific steps of which are:

[0085] Raw material+color masterbatch→mixing→vacuum feeding→raw material drying→single-screw extruder→color line extruder→spiral mold→sizing sleeve→spray vacuum calibrating box→spray cooling water tank→jet printer→ Crawler tractor → finished product inspection and packaging PVC-U pipe specifications; color masterbatch can be changed according to actual needs.

[0086] A kind of functional masterbatch, its raw material mass percentage is:

[0087]

[0088] The particle diameter of described nano bamboo charcoal material is 30nm;

Embodiment 3

[0090] A composite flame-retardant and antibacterial PVC-U drainage pipe, the mass percentage of its raw materials is:

[0091] Functional masterbatch 0.5%

[0092] PVC-U masterbatch 99.5%

[0093] A preparation method of a composite flame-retardant and antibacterial PVC-U drainage pipe, the specific steps of which are:

[0094] Raw material+color masterbatch→mixing→vacuum feeding→raw material drying→single-screw extruder→color line extruder→spiral mold→sizing sleeve→spray vacuum calibrating box→spray cooling water tank→jet printer→ Crawler tractor → finished product inspection and packaging PVC-U pipe specifications; color masterbatch can be changed according to actual needs.

[0095] A kind of functional masterbatch, its raw material mass percentage is:

[0096]

[0097] The particle diameter of described nano bamboo charcoal material is 30nm;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com