Multifunctional optical film and composite thereof, as well as multifunctional optical plate and manufacturing method thereof

A composition and multi-functional technology, applied in the direction of diffusing elements, etc., can solve the problems of functional layer performance, large thickness and poor performance affecting the optical film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

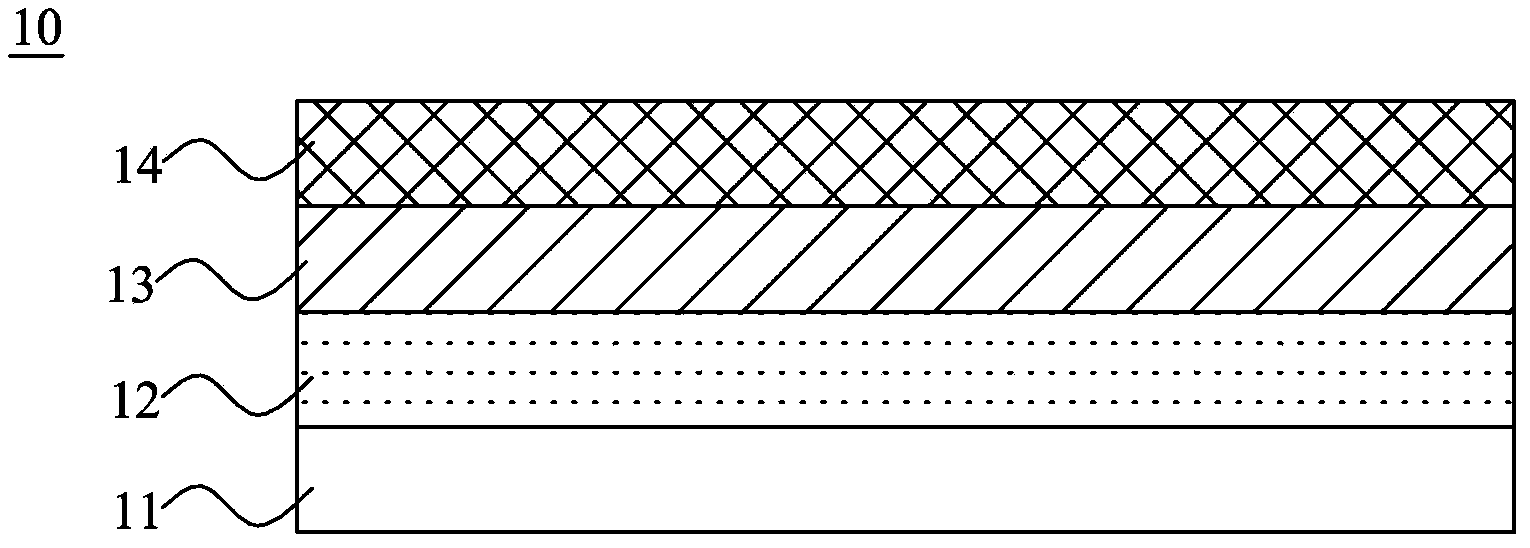

[0049] Please also refer to Figure 7 and Figure 8 , Figure 7 It is a flow chart of the co-extrusion process of the multifunctional optical board in an embodiment of the present invention, Figure 8 It is a schematic diagram of the co-extrusion device made of the multifunctional optical plate of the present invention. The present invention also provides a preparation method of the multifunctional optical plate. The preparation method may include, but is not limited to the following steps:

[0050] In step1, a co-extrusion device is provided. The co-extrusion device has a plurality of extruders and a co-extrusion compound die connected to the plurality of extruders, wherein the co-extrusion compound die is provided with a plurality of runners, and the extruder The quantity of the output machine and the quantity of flow channels can be based on the specific structure of the multifunctional optical plate, for example, according to the above-mentioned Figure 3-Figure 6 The d...

Embodiment 1

[0065] Iodine-doped polyacetylene (mass concentration of iodine in polyacetylene is 1ppm-50ppm) and polymethyl methacrylate resin (number average molecular weight is 70000-80000, purchased from: Taiwan Fude Polymer Co., Ltd.) , according to the proportion of 0.1% and 99.9% of the weight, respectively, into the high-speed mixer, fully stirred to form a composition, the composition is added to the screw extruder, mixed and extruded at a temperature of 210°C-245°C , after extrusion, it is pelletized by a pelletizer and cooled to form an antistatic masterbatch for later use.

[0066] Select a co-extrusion device 100, including a first extruder 101 and a second extruder 102, add the antistatic masterbatch to the first extruder 101, and knead at a temperature of 210°C-245°C to form a melt I , the control screw 103 extrudes the melt I under the rotating speed condition of 16mm / s; Polymethyl methacrylate resin (molecular weight is 70000-80000, purchased from: Taiwan Fude Polymer Co., ...

Embodiment 2 to Embodiment 6

[0068] The preparation method of embodiment 2 to embodiment 6 is identical with embodiment 1, and difference only is that the polyacetylene (the mass concentration of iodine in polyacetylene is 1ppm-50ppm) and polymethyl methacrylate resin (number average) of iodine doping The molecular weight is 70000-80000, purchased from: Taiwan Fude Polymer Co., Ltd.) with different weight percentages, wherein, corresponding to Examples 2 to 6, the weight percentages of iodine-doped polyacetylene are 5%, 10% in turn . ) are 95%, 90%, 85%, 80%, 75% and 70% by weight in sequence.

[0069] Wherein, embodiment 2 to embodiment 6 are to further investigate the content (wt%) of polyacetylene polymer conductive material containing halogen or alkali metal in the multifunctional optical board provided by the present invention, and the influence on the performance of multifunctional optical board . In this embodiment, iodine-doped polyacetylene is used as an example, but it is not limited thereto. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com