Production technology of high-strength wood plastic composite material

A wood-plastic composite material and production process technology, which is applied in the field of composite materials, can solve problems such as poor freeze-thaw resistance, water absorption warping, deterioration of anti-mildew and antibacterial performance, etc., and achieve the effect of increasing strength and reducing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

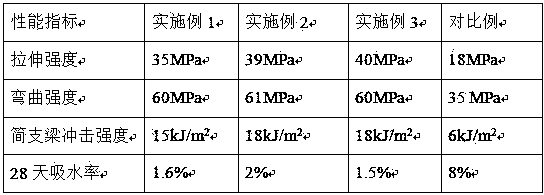

Examples

Embodiment 1

[0028] (1) Dry the wood powder so that the moisture content of the plant fiber is 0.4%;

[0029] (2) Put 60 parts of dried wood powder, 30 parts of thermoplastic PE and 10 parts of maleic anhydride grafted PP into a mixer, and mix it at high speed for 8 minutes, control the stirring speed at 350rpm, and control the temperature at 85°C;

[0030] (3) The mixed material is transported to the parallel twin-screw extruder through the transportation pipeline for the first granulation to obtain wood-plastic particles. The speed of the main machine is 400 rpm, the current is 75% of the rated current of the main machine, and the temperature is controlled during granulation. at 160°C;

[0031] (4) Then add 100 parts of wood-plastic particles, 2 parts of EBS, 2 parts of zinc stearate, and 10 parts of red iron oxide into the mixer and put them in the mixer for cold mixing for 10 minutes. The stirring speed is controlled at 200rpm and the temperature is controlled at 80 ℃, mix well;

[0...

Embodiment 2

[0035] (1) Dry the wood powder and straw powder so that the moisture content of the plant fiber is 0.3%;

[0036] (2) Put 30 parts of dried wood flour, 20 parts of straw powder, 10 parts of PE, 20 parts of PP and 8 parts of maleic anhydride grafted PE into a mixer, and mix them cold for 9 minutes, with the stirring speed controlled at 300rpm. The temperature is controlled at 80°C;

[0037] (3) The mixed material is transported to the parallel twin-screw extruder through the transportation pipeline for the first granulation to obtain wood-plastic particles. The speed of the main machine is 350rpm, the current is 70% of the rated current of the main machine, and the temperature is controlled at 180°C during granulation. ;

[0038] (4) Then add 100 parts of wood-plastic particles, 5 parts of EBS, 5 parts of calcium stearate, and 8 parts of iron oxide red into the mixer for 12 minutes of high-speed cold mixing. The stirring speed is controlled at 300 rpm and the temperature is co...

Embodiment 3

[0042] (1) Dry the wood powder and bamboo powder so that the moisture content of the plant fiber is 0.5%;

[0043] (2) Put 50 parts of dried wood powder, 22 parts of bamboo powder, 10 parts of PE, 15 parts of ABS, 8 parts of maleic anhydride grafted PP, and 5 parts of acrylic acid grafted PP in a mixer, and mix them cold for 10 minutes. The stirring speed is controlled at 200rpm, and the temperature is controlled at 85°C;

[0044] (3) The mixed material is transported to the parallel twin-screw extruder through the transportation pipeline for the first granulation to obtain wood-plastic particles. The speed of the main machine is 300 rpm, the current is 80% of the rated current of the main machine, and the temperature is controlled during granulation. at 190°C;

[0045] (4) Add 100 parts of wood-plastic particles, 1 part of polyol ester, 1 part of calcium stearate, and 1 part of iron oxide red into the mixer for 15 minutes of cold mixing. The stirring speed is controlled at 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com