Genetic engineering microorganism for producing ethanol

A genetic engineering and genetic technology, applied in the field of ethanol production by genetically engineered microorganisms, can solve the problems of not producing ethanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

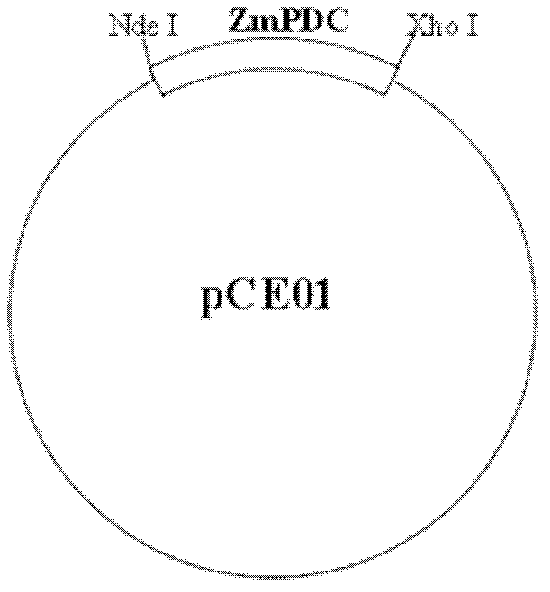

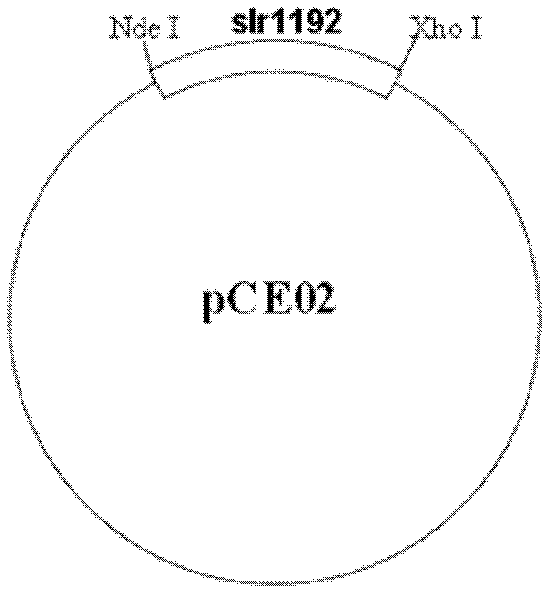

[0092] Example 1: Construction of vectors for expressing pyruvate decarboxylase and alcohol dehydrogenase

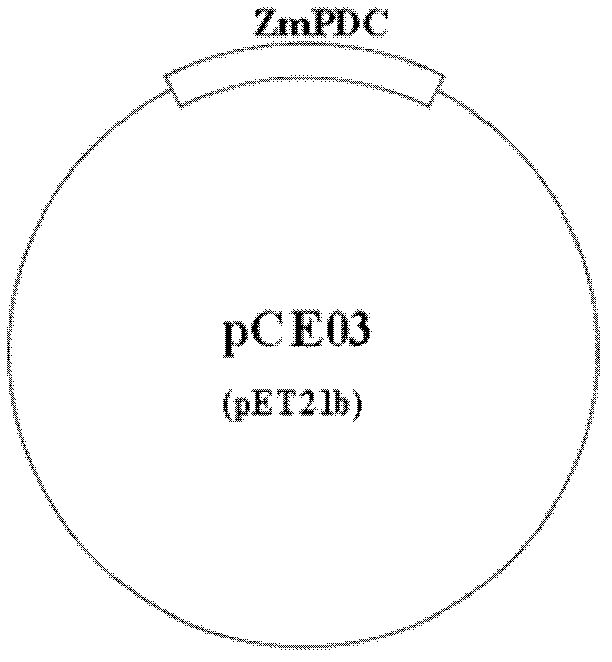

[0093] In order to exogenously introduce pyruvate decarboxylase into cyanobacteria and increase the production of pyruvate decarboxylase and alcohol dehydrogenase in cyanobacteria, the plasmid pCE03 capable of expressing the pyruvate decarboxylase gene ZmPDC derived from Zymomonas mobilis was constructed as follows And the plasmid pCE04 capable of expressing the endogenous alcohol dehydrogenase gene slr1192 derived from cyanobacterium PCC6803.

[0094] 1. Construction of plasmid pCE03

[0095] Using ZmPDC-F (5′-GCG GCA GCC ATA TGA GTT ATA CTG TCG-3′) and ZmPDC-R (5′-AGC TCG TCT CGA GTC TAG AGG AGC TTG-3′) as primers, motile Zymomonas Bacteria (Zymomonas Mobilis) genomic DNA was used as a template for PCR amplification, and according to the manufacturer's instructions, the PCR amplification product was cloned into pMD18-T vector (Takara, Catalog No.: D101A) to obtain pla...

Embodiment 2

[0098] Example 2: Construction of vectors for gene knock-in and gene knock-out

[0099] In order to confirm the role of pyruvate decarboxylase and alcohol dehydrogenase in the production of ethanol in cyanobacteria, and confirm that the production of ethanol in cyanobacteria can be improved by increasing the expression of the enzymes, the following constructions for the production of ethanol by the Prbc promoter The pyruvate decarboxylase gene (ZmPDC) and the alcohol dehydrogenase gene (slr1192) were integrated into the vector pCE09 at the slr0168 site of the cyanobacterial genome, and it was confirmed that by further increasing the pyruvate decarboxylase and alcohol dehydrogenase in ethanologenic cyanobacteria In order to increase the production of ethanol, a vector pCE11 for integrating the pyruvate decarboxylase gene (ZmPDC) and the alcohol dehydrogenase gene (slr1192) driven by the Prbc promoter into the cyanobacteria genome slr1193-1194 site was constructed as follows.

[0...

Embodiment 3

[0107] Embodiment 3: Transformation of cyanobacteria and screening of transformants

[0108] Transformation of cyanobacteria and selection of transformants were carried out as follows:

[0109] 1. Take 10 mL of cyanobacterial cells in the logarithmic growth phase (OD730 is about 0.5-1.0), and collect the cells by centrifugation; wash the cells twice with fresh BG11 medium, and then resuspend the cells in 1 mL of BG11 medium (1.5 g L -1 NaNO3, 40 mg L -1 K 2 HPO 4 ·3H 2 O, 36 mg L -1 CaCl2 2H2O, 6mg / L citric acid, 6mg / L ferric ammonium citrate, 1mg L -1 EDTA disodium salt, 20mg L -1 NaCO 3 , 2.9 mg L -1 h 3 BO 3 , 1.8 mg L -1 MnCl 2 4H 2 O, 0.22 mg L -1 ZnSO 4 7H2O, 0.39 mg L -1 NaMoO 4 2H 2 O, 0.079 mg L -1 CuSO 4 ·5H 2 O and 0.01 mg L -1 CoCl 2 ·6H 2 O).

[0110] 2. Take 0.2mL cell suspension into a new EP tube, add 2~3μg expression plasmid, mix well, and place at 30℃, 30μEm -2 the s -1 Incubate for 5 hours under light conditions.

[0111] 3. Spre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com