Additive for biogas fermentation

A biogas fermentation and additive technology, applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of low gas production rate and long time, and achieve the effect of improving gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] 1. Production of additives

[0010] It is prepared by uniformly mixing 30 kg of sucrose, 30 kg of flour, 3 kg of yeast powder and 40 kg of starch residue.

[0011] 2. Preparation of biogas digester and feed liquid

[0012] 1. Digester: 8 cubic meters

[0013] 2. Livestock and poultry manure is used as the fermentation raw material, and the percentage concentration of organic matter in the feed liquid of the biogas tank is between 2 and 5% (that is, the biogas has not yet started, and the percentage concentration of organic matter in the feed liquid of the biogas tank should usually be > 5% when the biogas is started), The pH value of the feed liquid is between 5 and 8.5.

[0014] 3. Experiment

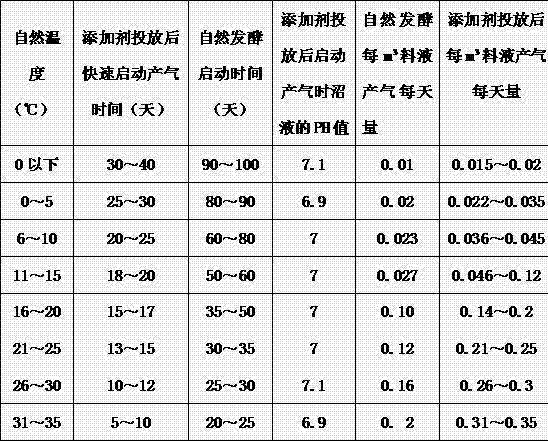

[0015] Take 4 kg of the above-mentioned additive, add it to the above-mentioned biogas digester at an outdoor temperature of 0-35°C, and compare the measured data with the start-up time without adding the additive as follows:

[0016]

[0017] Four, show according to abov...

Embodiment 2

[0020] 1. Production of additives

[0021] Mix 40 kg of sucrose, 30 kg of wheat bran, 30 kg of flour, and 4 kg of yeast powder

[0022] be made of.

[0023] 2. Preparation of biogas digester and feed liquid

[0024] 1. Digester: 100 cubic meters

[0025] 2. Use crop stalks as fermentation raw materials, and the percentage concentration of organic matter in the feed liquid of the biogas tank is between 2 and 5% (that is, the biogas has not yet started, and the percentage concentration of organic matter in the feed liquid of the biogas tank should usually be > 5% when the biogas is started). The pH value of the liquid is between 5 and 8.5.

[0026] 3. Experiment

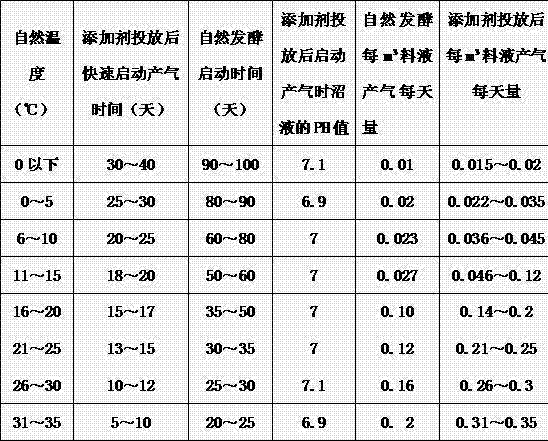

[0027] Take 50 kg of the above-mentioned additive, add it into the above-mentioned biogas digester at an outdoor temperature of 0-35°C, and compare the measured data with the start-up time without adding the additive as follows:

[0028]

[0029] Four, show according to above-mentioned experimental data, ado...

Embodiment 3

[0032] 1. Production of additives

[0033] It is prepared by uniformly mixing 45 kg of sucrose, 20 kg of rice bran, 25 kg of wheat bran and 10 kg of ammonium bicarbonate.

[0034] 2. Preparation of biogas digester and feed liquid

[0035] 1. Digester: 300 cubic meters

[0036] 2. Use aquaculture sewage as the raw material for fermentation, and the percentage concentration of organic matter in the feed liquid of the biogas tank is between 2 and 5% (that is, the biogas has not yet started, and the percentage concentration of organic matter in the feed liquid of the biogas tank should usually be > 5% when the biogas is started). The pH value of the liquid is between 5 and 8.5.

[0037] 3. Experiment

[0038] Take 150 kg of additives and add them to the above-mentioned biogas digester at an outdoor temperature of 0-35°C. The specific data measured and compared with the start-up time without adding additives are as follows:

[0039]

[0040] Four, show according to above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com