Method for preparing column-shaped nano-tungsten

A kind of metal tungsten and nanotechnology, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems that are not suitable for insulating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This embodiment includes the following steps:

[0015] (1) Fabrication of the sample holder

[0016] Car out an aluminum cylinder with a specified size, with an outer diameter of 5.8cm and an inner diameter of 5.1cm. The wall of the cylinder is divided into four rows of holes. The distance between the two holes in each row is 2.0cm, and the sample holder is 2.5cm. In the well, the sample is fixed on the sample holder.

[0017] (2) Cleaning of the substrate

[0018] Graphite substrates of 1cm*1cm were ultrasonically cleaned in ethanol, acetone, and deionized water for 10 minutes in sequence, and then dried with high-pressure airflow. Finally it is fixed at a specific angle on the sample holder.

[0019] (3) Preparation of nano-columnar tungsten film

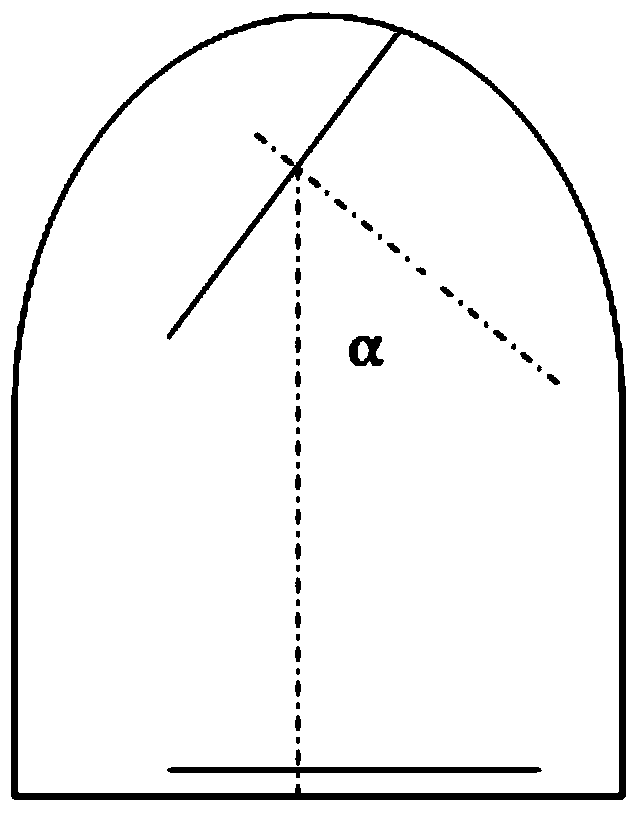

[0020] Using the method of grazing angle deposition and oblique growth, under the conditions of background vacuum 3*10-4Pa, current 0.15A, and voltage 300V, by changing the angle α between the normal direction of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com