Method for measuring iodine content in iodine absorption circulating liquid

A technology of absorption cycle and iodine content, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problem of lack of iodine circulation absorption liquid analysis and determination method of iodine content. , to achieve the effect of improving precision and accuracy, good repeatability and reproducibility, and stable analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

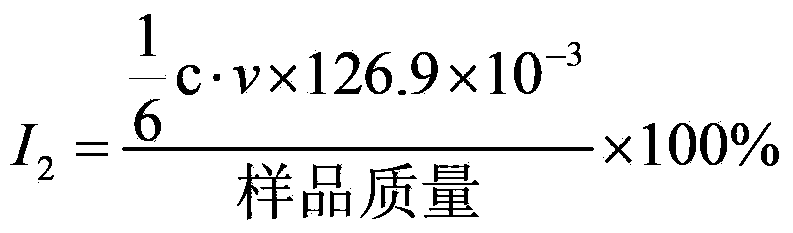

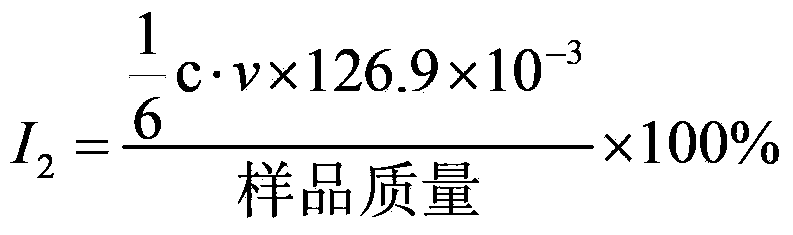

Method used

Image

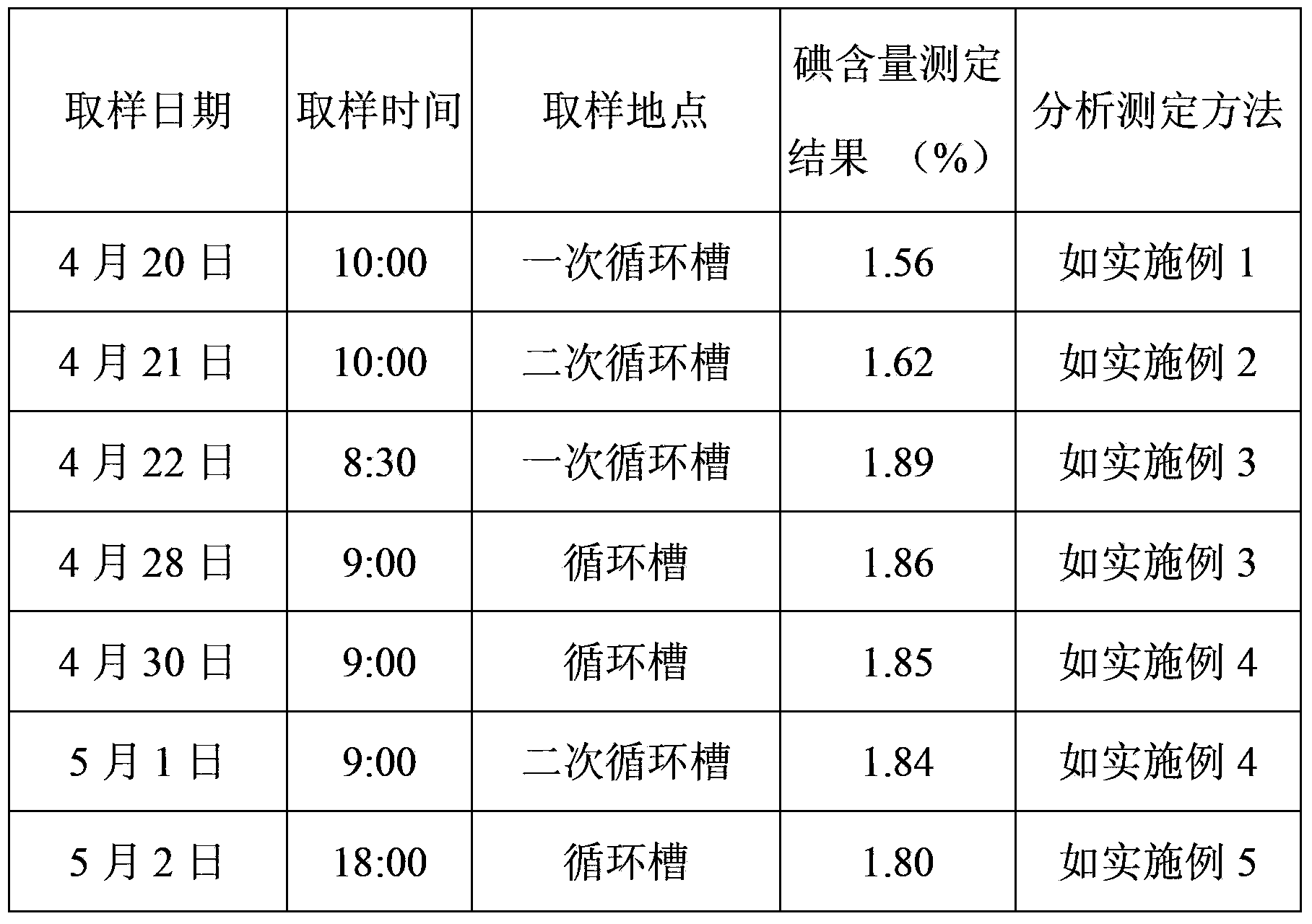

Examples

Embodiment 1

[0077] (1) Accurate sampling and dilution:

[0078] Sampling the circulating liquid produced by the process of extracting iodine with wet phosphoric acid from the absorption circulation tank to be determined, accurately weighed 0.4g of the fully mixed circulating liquid sample, accurate to 0.0001g, and added 80mL of it to a 250mL iodine measuring bottle Dilute with water, add 2mL of hydrochloric acid with a concentration of 1mol / L, shake well;

[0079] (2) Add saturated bromine water:

[0080] Add 14-16mL saturated bromine water and let stand for 5min;

[0081] (3) Add sodium formate solution and mix well:

[0082] Add 5 mL of sodium formate solution with a mass concentration of 10% to the solution obtained in step (2), mix well, and let it stand until the yellow color fades;

[0083] (4) Heat to boiling, add sodium fluoride solution after cooling:

[0084] Place the solution obtained in step (3) on an electric furnace and heat it to boiling for 2 minutes, then cool to roo...

Embodiment 2

[0094] (1) Accurate sampling and dilution:

[0095] Sampling the circulating liquid produced by the process of extracting iodine with wet-process phosphoric acid from the absorption circulation tank to be determined, accurately weighed 0.45g of the fully mixed circulating liquid sample, accurate to 0.0001g, and added 80mL of it to a 250mL iodine measuring bottle Dilute with water, add 2 mL of hydrochloric acid with a concentration of 1 mol / L, and shake well;

[0096] (2) Add saturated bromine water:

[0097] Add 14.5mL saturated bromine water and let stand for 5min;

[0098] (3) Add sodium formate solution and mix well:

[0099] Add 5 mL of sodium formate solution with a mass concentration of 10% to the solution obtained in step (2), mix well, and let it stand until the yellow color fades;

[0100] (4) Heat to boiling, add sodium fluoride solution after cooling:

[0101] Place the solution obtained in step (3) on an electric furnace and heat it to boiling for 2.5 minutes, ...

Embodiment 3

[0111] (1) Accurate sampling and dilution:

[0112] Sampling the circulating liquid produced by the process of extracting iodine with wet-process phosphoric acid from the absorption circulation tank to be determined, accurately weighed 0.5g of the fully mixed circulating liquid sample, accurate to 0.0001g, and added 80mL of it to a 250mL iodine measuring bottle Dilute with water, add 3mL hydrochloric acid with a concentration of 1mol / L, shake well;

[0113] (2) Add saturated bromine water:

[0114] Add 15mL saturated bromine water and let stand for 5min;

[0115] (3) Add sodium formate solution and mix well:

[0116] Add 5 mL of sodium formate solution with a mass concentration of 10% to the solution obtained in step (2), mix well, and let it stand until the yellow color fades;

[0117] (4) Heat to boiling, add sodium fluoride solution after cooling:

[0118] Place the solution obtained in step (3) on an electric furnace and heat it to boiling for 2.5 minutes, then cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com