Method for manufacturing rear side local contact silicon solar cell

A silicon solar cell, local contact technology, applied in the final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of silicon wafer pollution, difficult to burn through the passivation layer, difficult ohmic contact, etc., and achieve the goal of reducing damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The purpose and effects of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

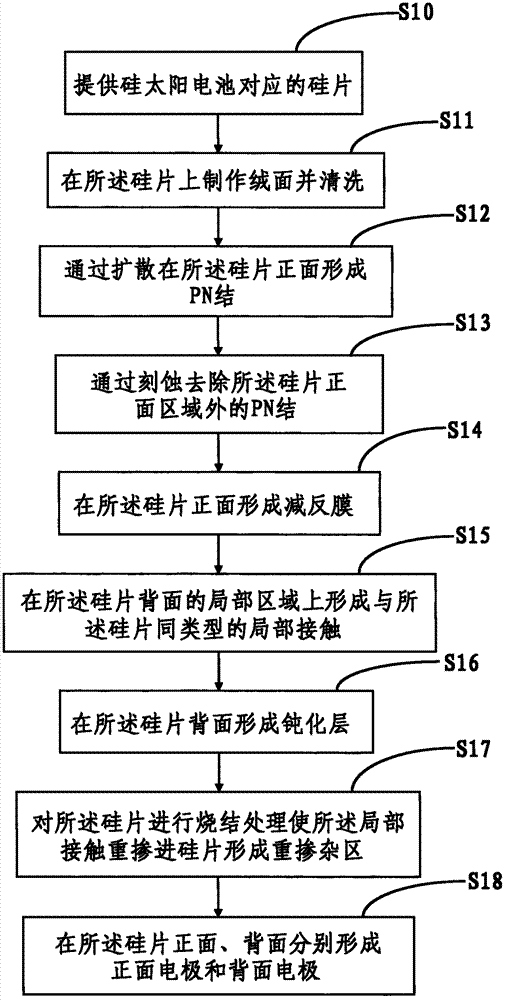

[0022] see figure 1 , the method for manufacturing a silicon solar cell with backside partial contact firstly proceeds to step S10 to provide a silicon wafer corresponding to the silicon solar cell. In this embodiment, the silicon wafer is a P-type single crystal silicon wafer, its resistivity is 0.5˜10 Ω·cm, its thickness is 200 μm˜400 μm, and its size is 125 mm×125 mm.

[0023] Then continue to step S11, making a textured surface on the silicon wafer and cleaning it, adopting different texturing methods for single crystal silicon wafers and polycrystalline silicon wafers, and using alkaline solutions such as potassium hydroxide or sodium hydroxide for single crystal silicon wafers Form a pyramid-like suede surface on the silicon wafer. When it is a polycrystalline silicon wafer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com