Multimetal reforming catalyst and preparation and applications thereof

A reforming catalyst and catalyst technology, which can be used in physical/chemical process catalysts, reformed naphtha, chemical instruments and methods, etc. The effect of carbon deposition capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

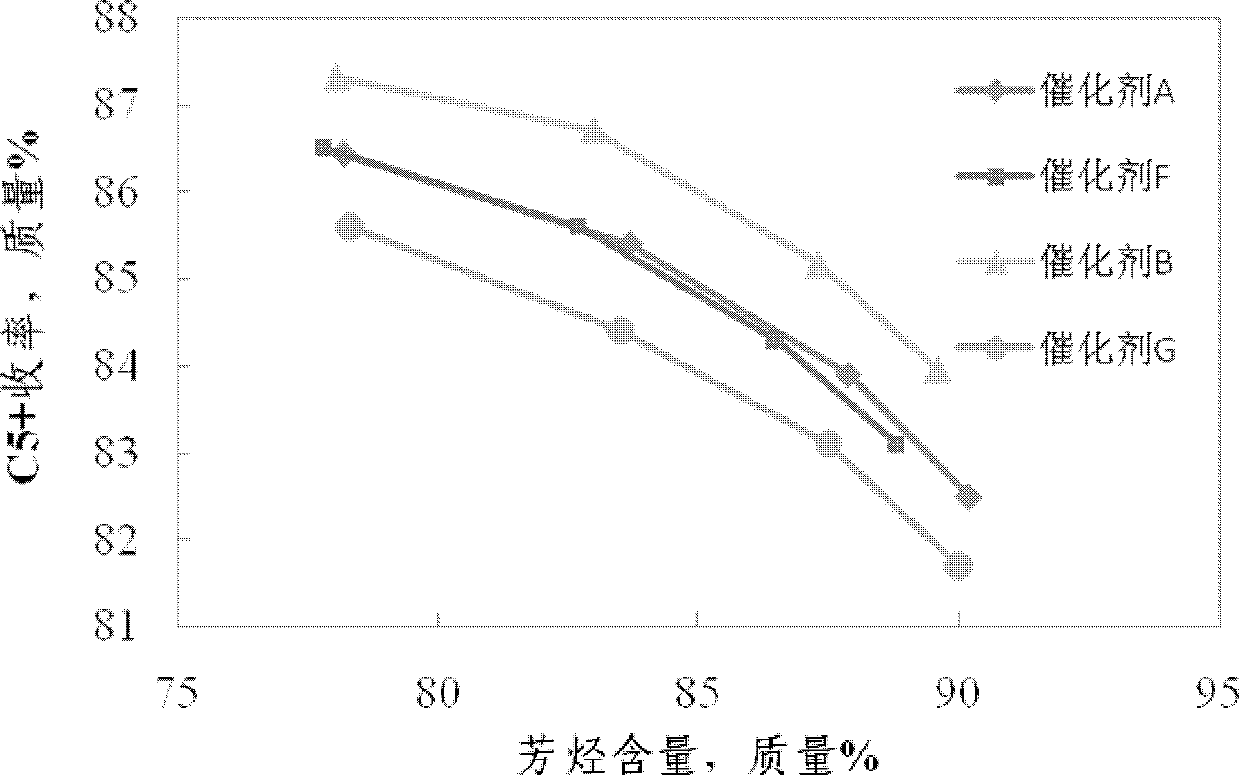

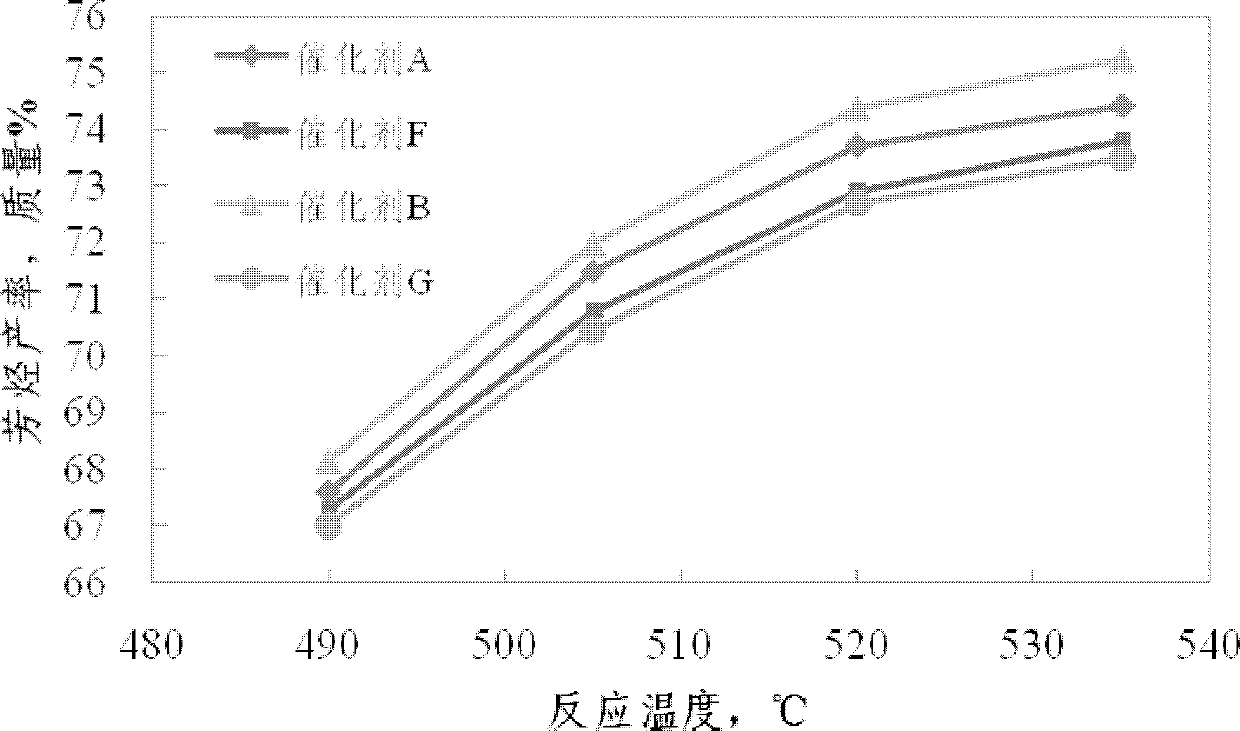

Examples

preparation example Construction

[0041]The preparation of the catalyst provided by the invention can adopt two methods, one is to introduce Sm and Ce by sub-leaching method, and the other is to introduce Sm and Ce by co-impregnation method.

[0042] The preparation method of the catalyst that introduces Sm and Ce by sub-impregnation method includes impregnating the inorganic oxide carrier containing IVA group metal with the solution containing Sm and Ce respectively, introducing Sm and Ce respectively in the carrier, and then using the solution containing VIII The carrier is impregnated with the solution of the group metal compound, and the carrier obtained after each impregnation and introduction of the metal component needs to be dried and calcined. Preferably, the carrier introduced with Sm and Ce is calcined with air containing water vapor, and the content of water in the air is preferably 1 ~8% by mass.

[0043] The preparation method of the catalyst that adopts the co-impregnation method to introduce Sm...

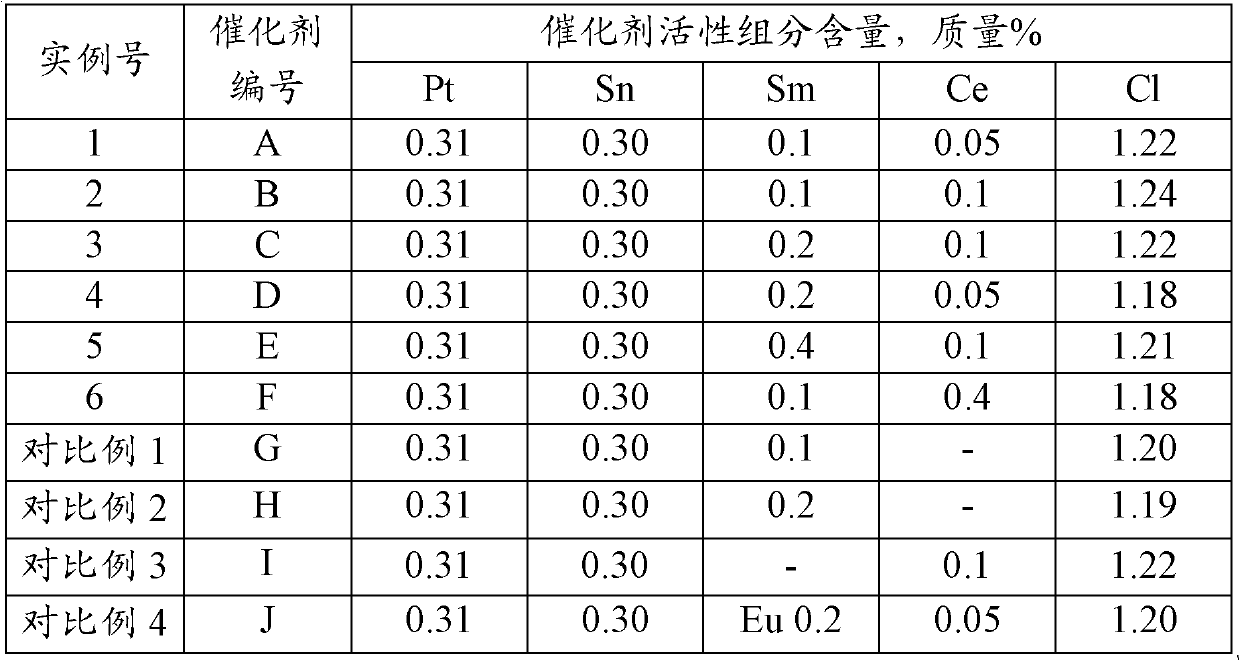

example 1

[0058] Catalysts described in the present invention are prepared.

[0059] (1) Preparation of Sn-containing Al 2 o 3 carrier

[0060] According to the method of CN1150169A, 100g of SB aluminum hydroxide powder (manufactured by Sasol Company) was mixed with an appropriate amount of deionized water, so that the liquid / solid mass ratio was 2.0, and stirred for slurrying. Add 7.5mL of dilute nitric acid with a volume ratio of 1:1, 30g of urea and a predetermined amount of stannous chloride hydrochloric acid solution, so that the Sn content in the hydrochloric acid is 0.3% by mass relative to the dry basis alumina, stir for 1 hour, and add 30g Kerosene and 3g fatty alcohol polyoxyethylene ether are dropped into balls in the oil ammonia column. The wet bulb was solidified in ammonia water for 1 hour, then filtered, rinsed with deionized water for 2 to 3 times, dried at 60°C for 6 hours, dried at 120°C for 10 hours, and calcined at 600°C for 4 hours to obtain the Sn-containing car...

example 2

[0068] Catalyst B is prepared by the method of example 1, the difference is that (3) step prepares the used CeCl of impregnation solution 3 ·7H 2 The amount of O is 0.2658g, and the active component content of the prepared catalyst B is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com