Method for improving water solubility of nanomaterial through surface modification and nanomaterial modified by method

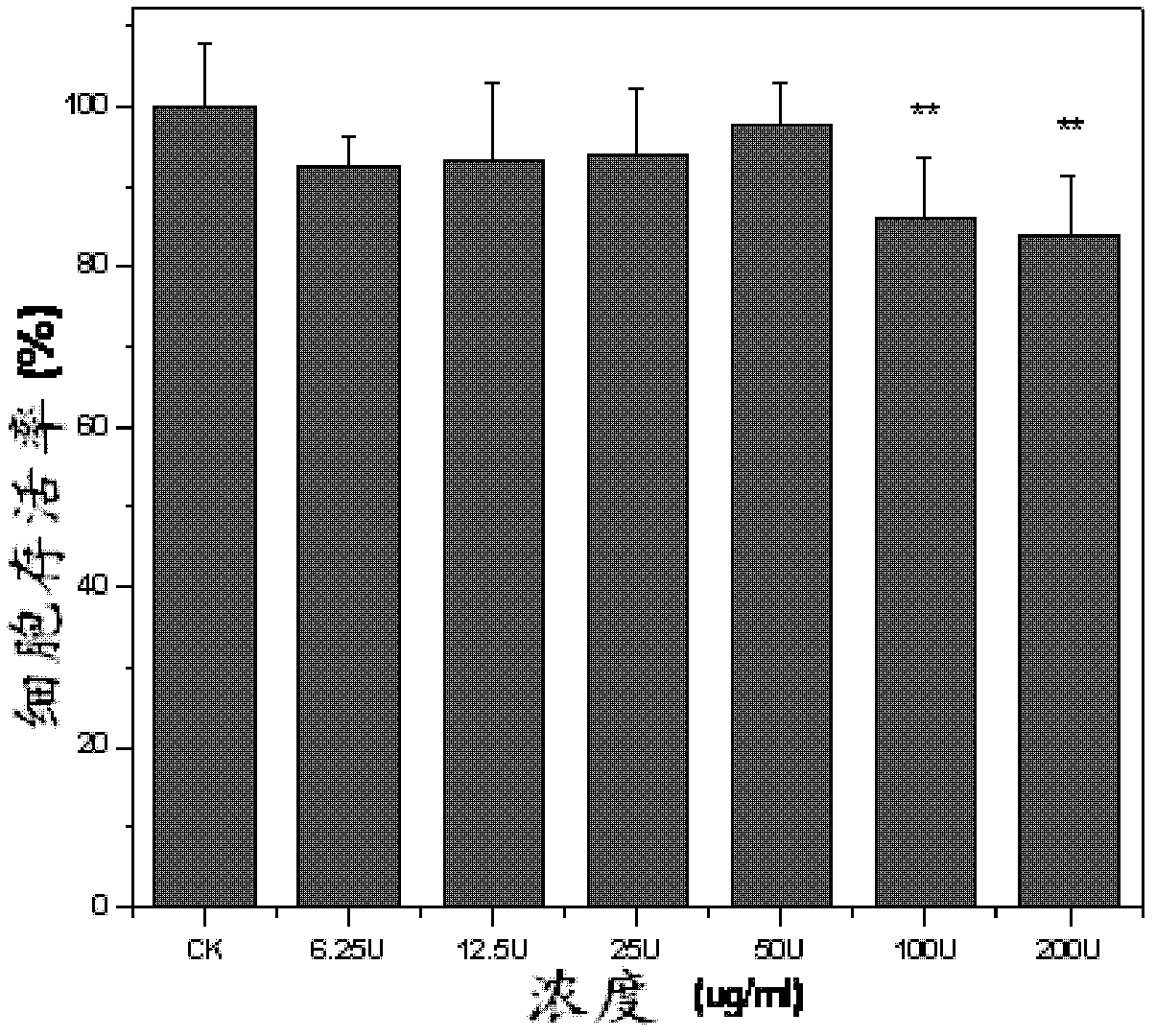

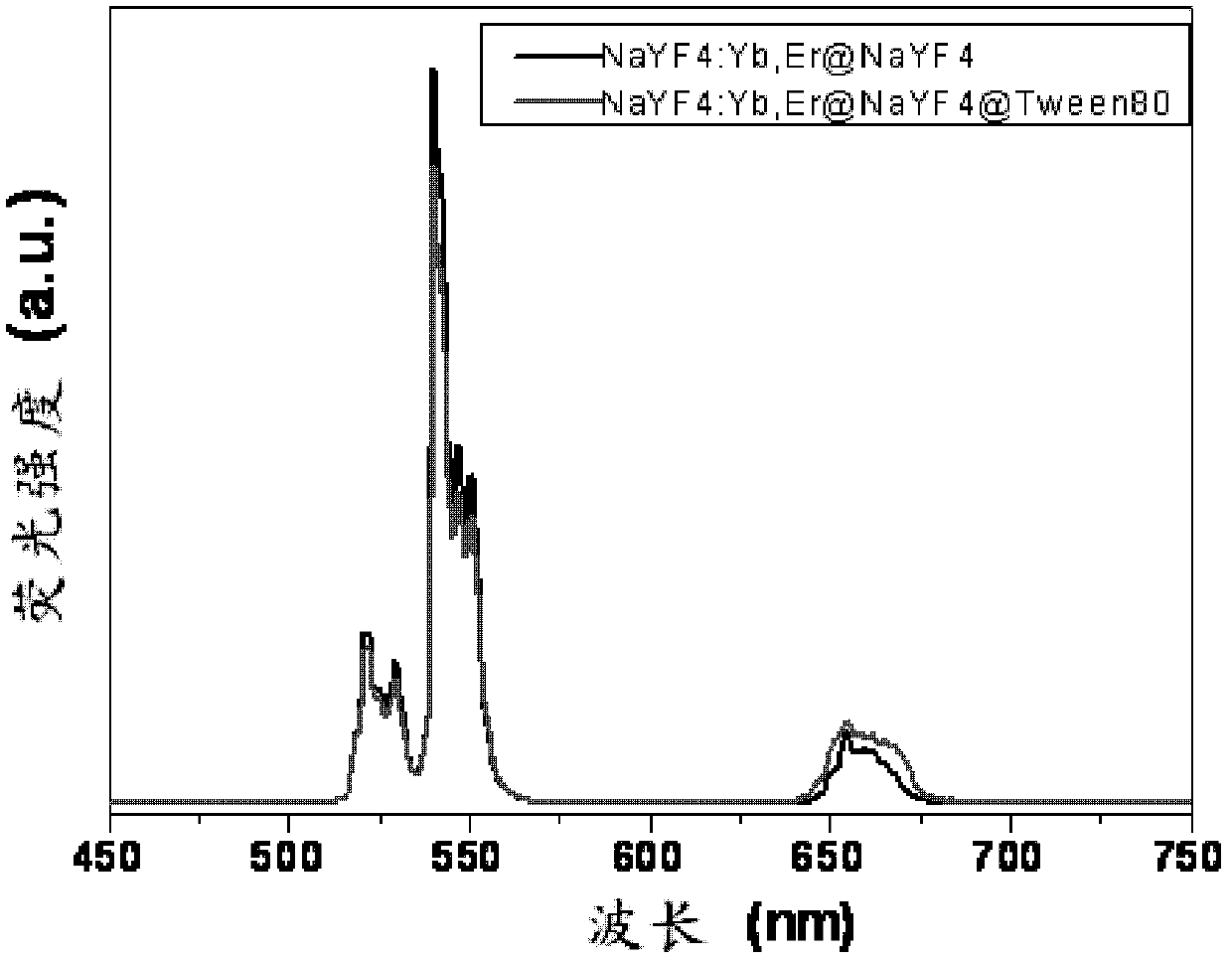

A nanomaterial and surface modification technology, applied in the field of nanomaterials, can solve the problems of high toxicity of polymers, expensive polymers, and easy aggregation of particles, and achieve the effect of low cytotoxicity, simple method, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh up 3 mg of up-converting fluorescent nanoparticles and add it into 2 mL of cyclohexane to prepare a solution of up-converting fluorescent nanoparticles. Then sonicate for 20 minutes until the up-converting fluorescent nanoparticles are completely dissolved in the organic solvent, add 20 μL of Tween-20, and stir at 1250 r / min for 1 h until the Tween-20 is completely dissolved in the organic solvent for up-conversion Nano fluorescent nanoparticle solution. Then put the up-converting fluorescent nanoparticles solution in a water bath, heat and stir, add 10 mL of deionized water, keep the temperature at 70° C. for 4 hours, until the organic solvent evaporates completely, the solution becomes clear and transparent, and the reaction ends. After the reaction, the reaction solution is centrifuged at a speed of 12,000 rpm in a centrifuge, and the up-conversion nanoparticles after centrifugation are washed once with deionized water and dried to collect the powder, which is ...

Embodiment 2

[0041] Weigh 5 mg of up-converting fluorescent nanoparticles and add it into 3 mL of cyclohexane to prepare a solution of up-converting fluorescent nanoparticles. Then sonicate for 30 minutes until the upconverting fluorescent nanoparticles are completely dissolved in the organic solvent, add 50 μL of Tween-40, and stir at 1700 r / min for 2 hours until the Tween-40 is completely dissolved in the organic solvent to obtain upconverting nanoparticles. Fluorescent Nanoparticle Solution. Then put the up-converting nano fluorescent nanoparticle solution in a water bath, heat and stir, add 8mL of phosphate buffer solution with a concentration of 0.01mol / L, keep the temperature at 40°C for 5 hours, until the organic solvent is volatilized and the solution is clear and transparent , the reaction ends. After the reaction, the reaction solution is centrifuged at a speed of 10,000 rpm in a centrifuge, and the centrifuged up-conversion nanoparticles are washed once with deionized water and...

Embodiment 3

[0043] Weigh 5 mg of up-converting fluorescent nanoparticles and add it into 10 mL of cyclohexane to prepare an up-converting fluorescent nanoparticles solution. Then sonicate for 25 minutes until the upconversion fluorescent nanoparticles are completely dissolved in the organic solvent, add 30 μL of Tween-60, and stir at 2400r / min for 2h until the Tween-60 is completely dissolved in the organic solvent to obtain the upconversion nanoparticle. Fluorescent Nanoparticle Solution. Then put the up-conversion nano fluorescent nanoparticle solution in a water bath, heat and stir, add 12mL of distilled water, keep the temperature at 80°C for 3 hours, until the organic solvent evaporates completely, the solution is clear and transparent, and the reaction ends. After the reaction, the reaction solution was centrifuged at a speed of 11,000 rpm in a centrifuge, and the centrifuged up-conversion nanoparticles were washed once with distilled water and then dried, and the powder was collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com