Method for detecting paeoniflorin

A technology for paeoniflorin and content, which is applied in the fields of medicine and chemistry, can solve the problems of long analysis time, complex pretreatment, online monitoring of difficult paeoniflorin, etc., and achieves the effects of rapid analysis, reduced instrument noise, and accurate and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] 1 Instruments and reagents

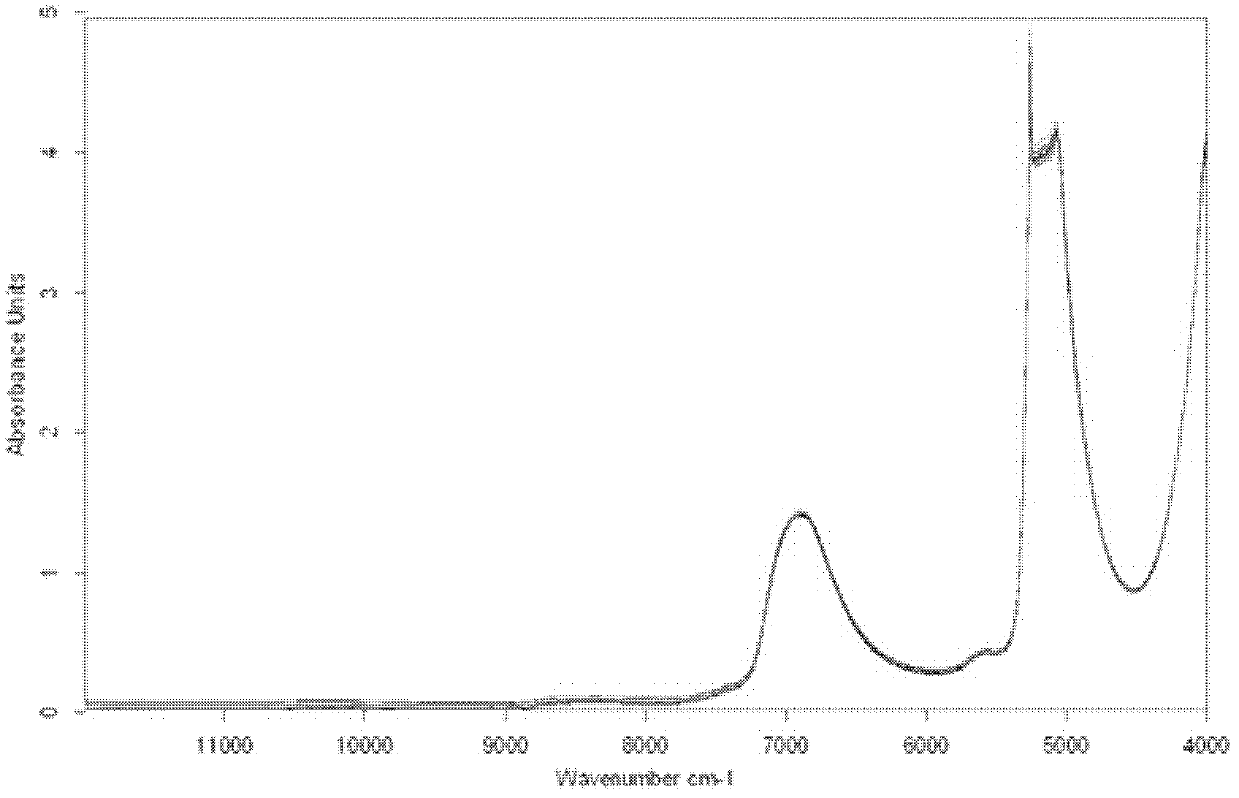

[0072] BRUKER TENSOR37 Fourier transform near-infrared spectrometer (Bruker, Germany), equipped with quantitative analysis software OPUS 6.5 (Bruker, Germany); Agilent1100 high performance liquid chromatography (Agilent Technology, USA); Mettler XS105 electronic balance (Shanghai Mei Teller Toledo Instrument Co., Ltd.); Paeoniflorin standard substance (National Institute for the Control of Pharmaceutical and Biological Products, batch number: 110736-201035, in 96.5%); Water for extraction is purified water, and water for liquid phase is ultrapure water (Millipore), Chromatographic acetonitrile (Merck, Germany), and other reagents were of analytical grade.

[0073] The three batches of Radix Paeoniae Rubra were all produced in Inner Mongolia.

[0074] 2HPLC Determination of Paeoniflorin Content

[0075] 2.1 Preparation of paeoniflorin standard substance

[0076] Paeoniflorin 2.66mg (according to 96.5%) was dissolved in a 5ml volumetric fla...

Embodiment 2

[0093] 1 Instruments and reagents

[0094] Three batches of Paeoniae Alba were all produced in Anhui.

[0095] All the other are with embodiment 1.

[0096] 2HPLC Determination of Paeoniflorin Content

[0097] 2.1 Preparation of paeoniflorin standard substance

[0098] With embodiment 1.

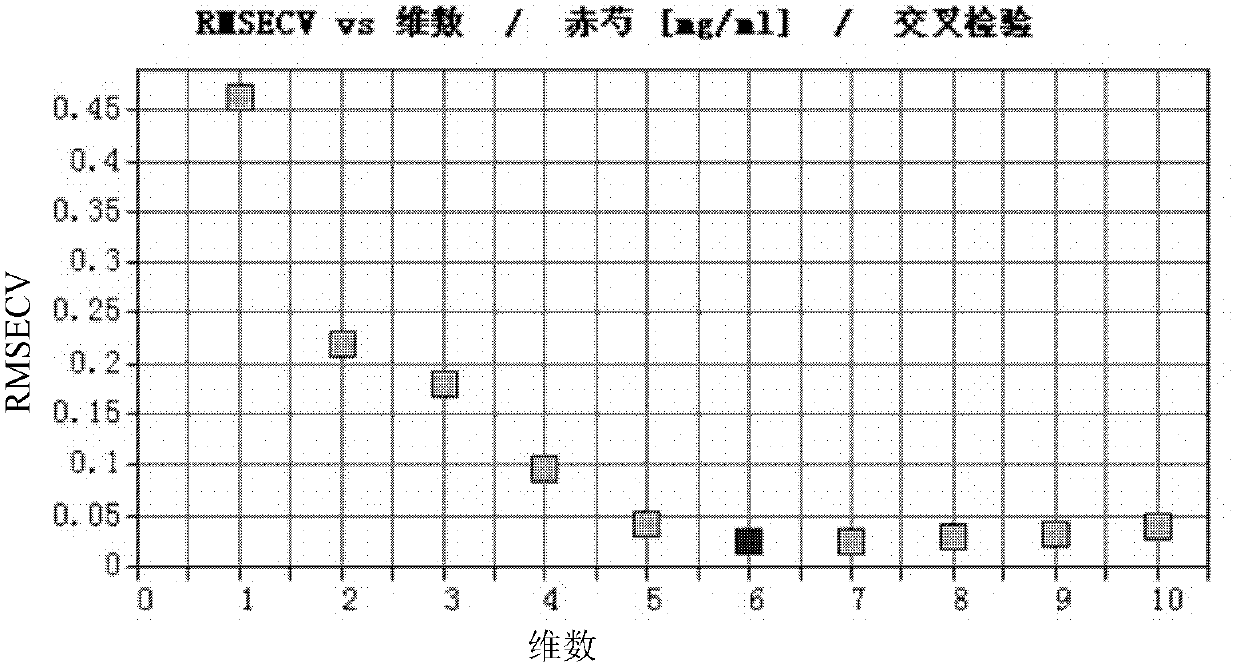

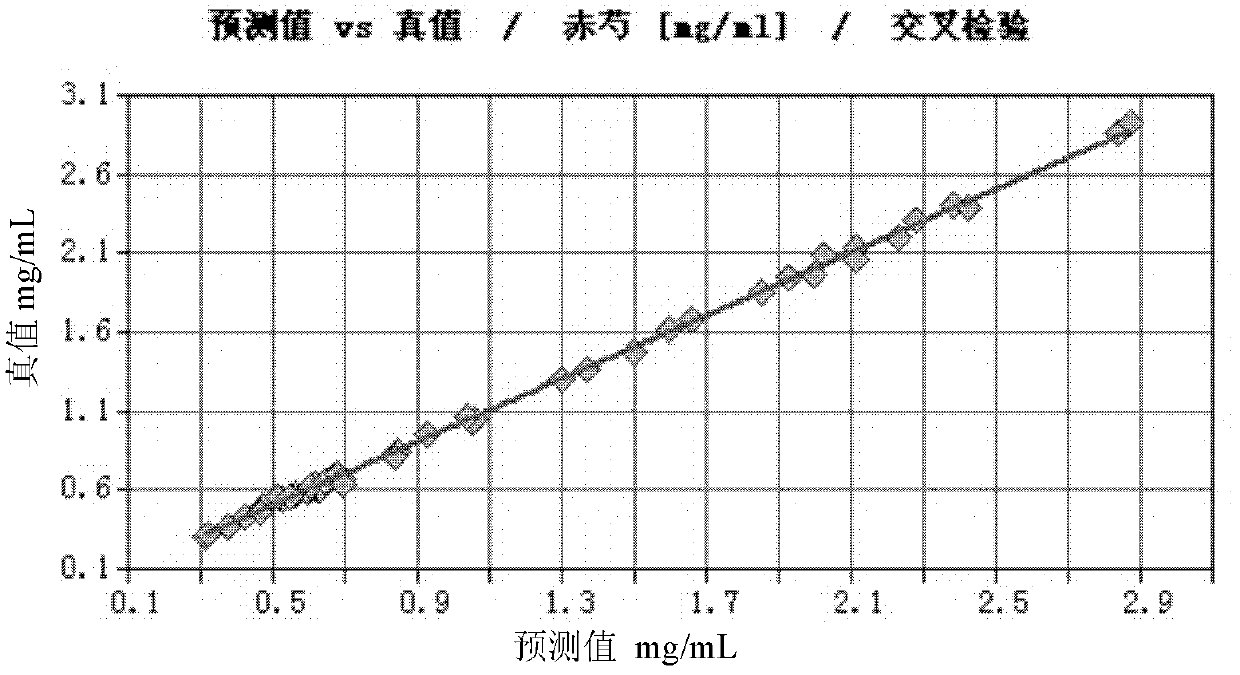

[0099] 2.2 Preparation of calibration set samples and validation set samples

[0100] Three batches of Radix Paeoniae Alba, each batch weighed 400g of medicinal materials, added 10 times the amount of purified water into a 5L round bottom flask, decocted with a 5L electric heating mantle until it boiled slightly for one hour; after the first decoction, add 8 times Measure purified water, decoct to a slight boil for one hour. Take 10mL extract every 10min for each decoction, and the mixture of the first decoction and the second decoction is also used as a sampling point. A total of 72 samples were obtained through three batch extraction processes. Among them, 56 extracts were selected ...

Embodiment 3

[0115] 1 Instruments and reagents

[0116] The three batches of peony bark are all produced in Anhui.

[0117] All the other are with embodiment 1.

[0118] 2HPLC Determination of Paeoniflorin Content

[0119] 2.1 Preparation of paeoniflorin standard substance

[0120] With embodiment 1.

[0121] 2.2 Preparation of calibration set samples and validation set samples

[0122] Three batches of peony cortex, weigh 400g of medicinal materials for each batch, add 10 times the amount of purified water into a 5L round bottom flask, decoct with a 5L electric heating mantle until it boils slightly for one hour; after the first decoction, add 8 times the amount of purified water , and cook until slightly boiled for one hour. Take 10mL extract every 10min for each decoction, and the mixture of the first decoction and the second decoction is also used as a sampling point. A total of 74 samples were obtained through three batch extraction processes. Among them, 58 extracts were selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com