Lithium ion battery positive pole piece and preparation method thereof

A lithium-ion battery, positive electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of complex technical solutions, can not solve the problem of battery over-discharge, etc., to reduce the response speed and prolong battery life , The effect of slowing down the discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

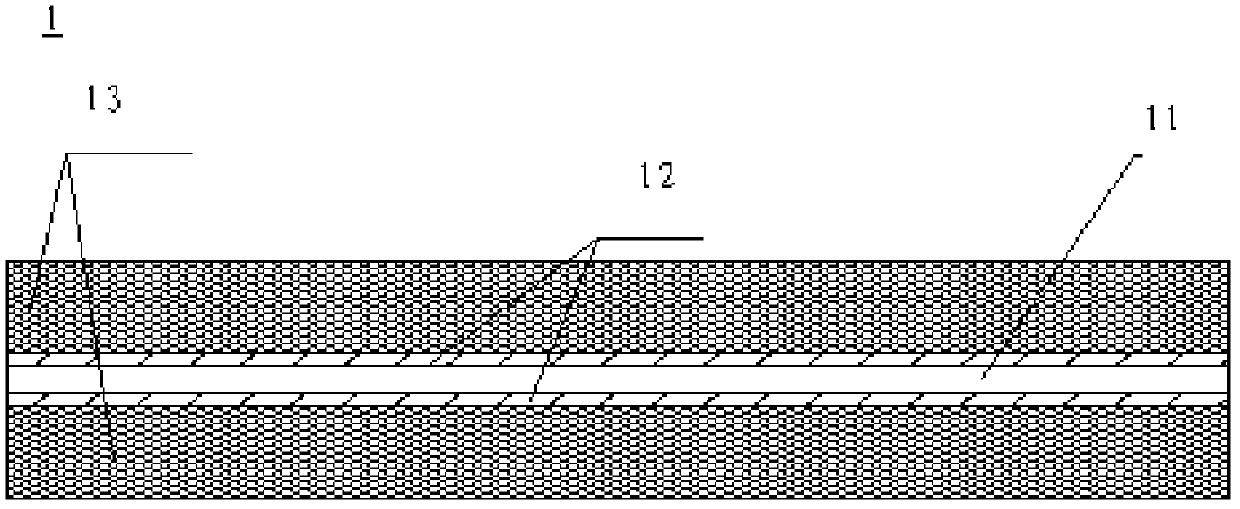

[0034] Such as figure 1 As shown, the present invention provides a method for preparing a positive electrode sheet of a lithium ion battery, the preparation method at least includes the steps: first, after coating a lithium iron phosphate mixed slurry layer 12 on at least one surface of a current collector 11, drying Then, on the lithium iron phosphate mixed slurry layer, an active coating 13 is applied and dried to prepare the positive electrode sheet of the lithium ion battery; the material of the active coating is nickel cobalt lithium manganate, lithium manganate or One or several kinds of lithium cobalt oxides.

[0035] Specifically, first coat a layer of mixed slurry mainly composed of lithium iron phosphate material (also including binder PVDF and conductive agent SP) on one surface or the upper and lower surfaces of the current collector 11, and dry to form lithium iron phosphate Mixed slurry layer 12; then one or more of nickel-cobalt lithium manganese oxide, lithium...

Embodiment 1

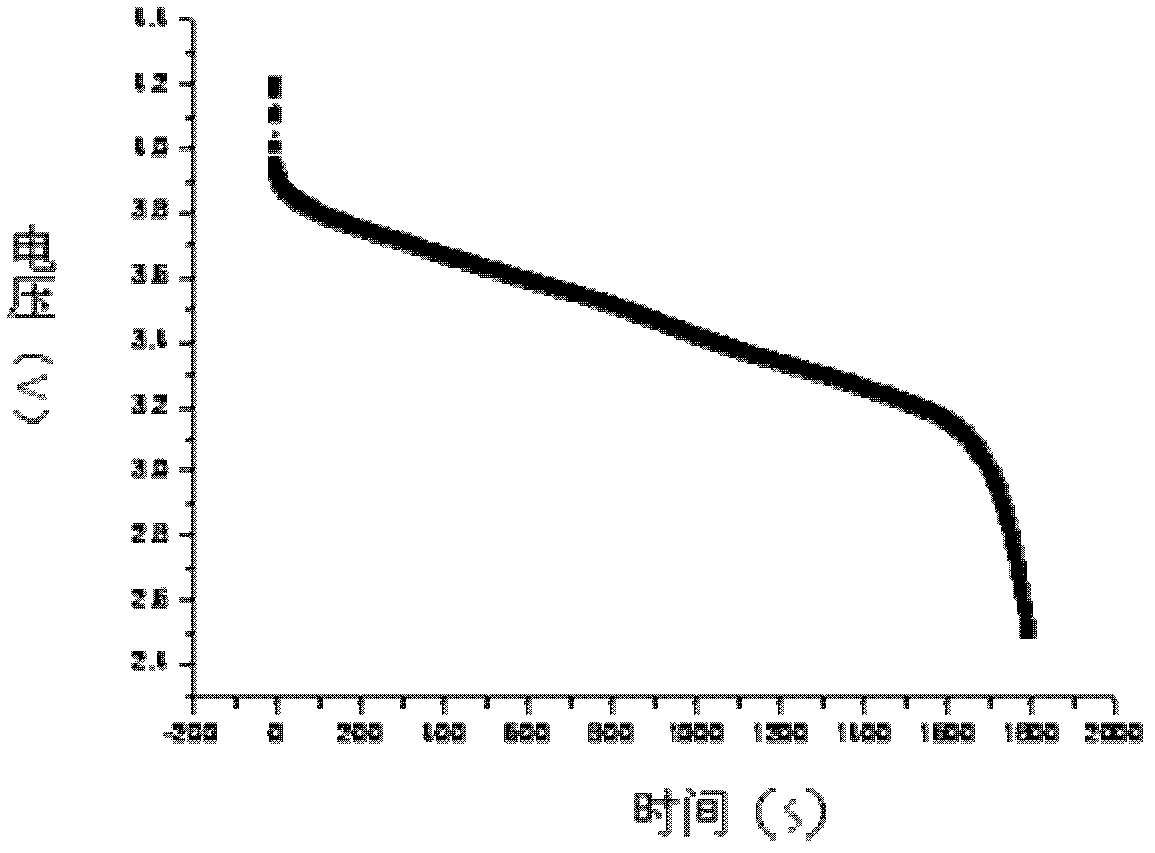

[0044]Preparation of a lithium-ion battery positive electrode sheet: Lithium iron phosphate, conductive agent SP and binder polyvinylidene fluoride (PVDF) are mixed into a slurry with NMP as a solvent in a weight ratio of 91:4:5, and evenly coated Cover on the aluminum foil substrate (current collector), and form a double-layer 5u thick coating after drying. Dry mix 9.3kg lithium manganate and 0.3kg SP in advance, then add 0.4kg PVDF NMP solution and mix at room temperature to form a slurry, evenly coat on the lithium manganate coating, dry, roll, and cut into positive electrodes pole piece. A lithium battery is made from the positive pole piece, and it is measured in experiments that the lithium ion battery with the positive pole piece is discharged to 2.5V 8.7 minutes later than the existing lithium iron phosphate battery.

Embodiment 2

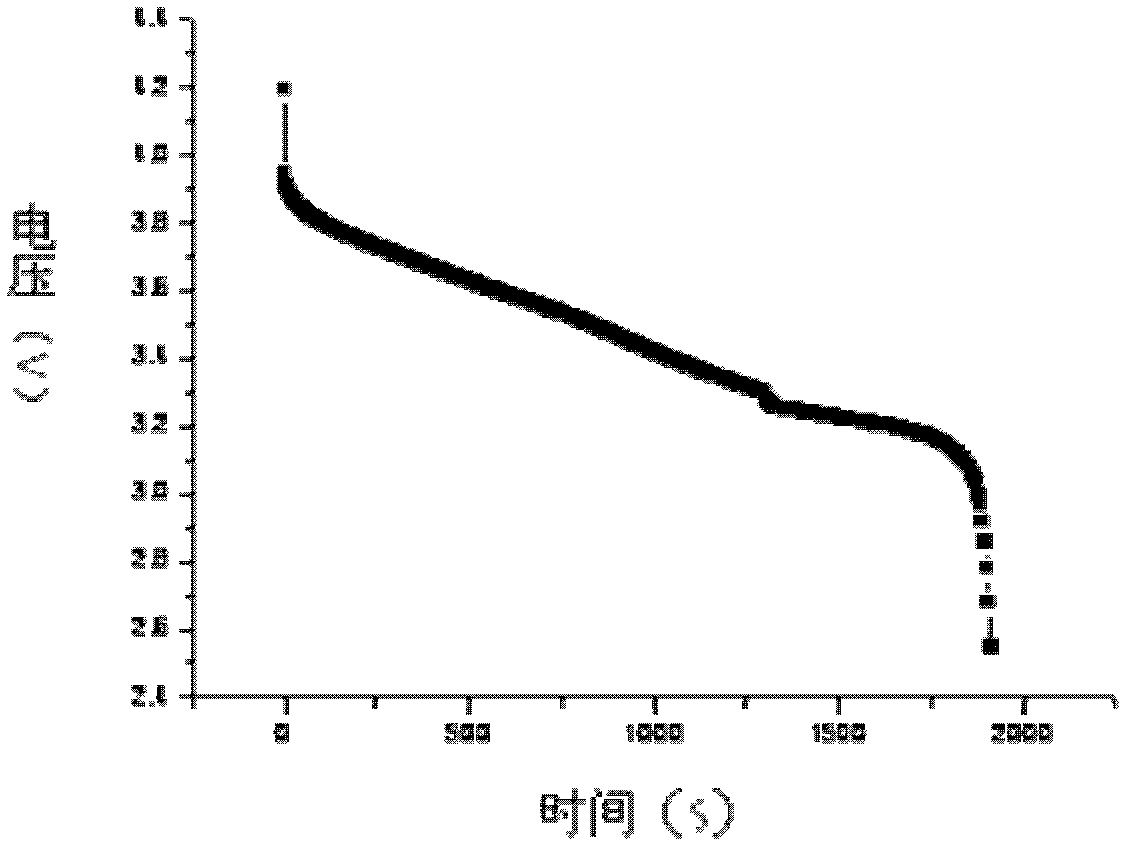

[0046] Preparation of a lithium-ion battery positive pole piece: Lithium iron phosphate, conductive agent SP and binder PVDF are mixed in a weight ratio of 91:4:5, and NMP is used as a solvent to form a slurry, and evenly coated on an aluminum foil substrate , formed a double-layer 5u thick coating after drying. Dry mix 9.3kg nickel-cobalt lithium manganate and 0.3kg SP in advance, then add 0.4kg PVDF NMP solution and mix at room temperature to form a slurry, which is evenly coated on the nickel-cobalt lithium manganese oxide coating, dried, and rolled. Cut into positive pole pieces. A lithium battery is made from the positive electrode sheet. Experiments have measured that the discharge of the lithium ion battery with the positive electrode sheet to 3.8V is delayed by 11.2 minutes compared with the existing lithium iron phosphate battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com