Wood-plastic composite board and preparation technology and equipment thereof

A preparation process and wood-plastic composite technology, which is applied in the field of building materials, can solve the problems of reducing the environmental protection of composite boards, reducing the amount of consumption, complex processes, etc., and achieve the effects of prolonging the effective service life, excellent performance of composite boards, and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

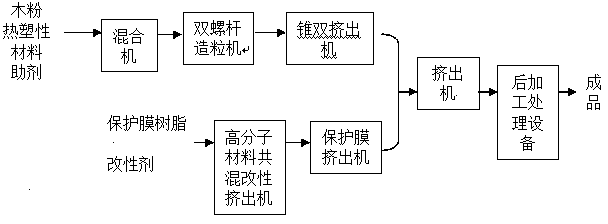

[0035] The specific embodiments of the present invention will be described below. The invention discloses a wood-plastic composite board. The wood-plastic composite board includes a core layer material and a surface protective film material. The core layer material includes wood powder, a thermoplastic material and an auxiliary agent. In order to save costs, recycled HDPE can be used as thermoplastic materials, and rice husks, crop residues and four twigs can be used as raw materials for wood flour. Surface protective film materials include protective film resins and modifiers. Among them, the wood powder in the core material is 51-60%, and the thermoplastic material is 35-40%. The above percentages are mass percentages. Modifiers include anti-ultraviolet agents, antifungal compatibilizers and lubricants.

[0036] The invention also discloses the preparation process of the above-mentioned wood-plastic composite board, which comprises the following steps:

[0037] Core material: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com